Step-by-step adaptation

Are you ready to take the next step in advancing your networked production? Boost the efficiency and quality of your production and maintain your competitive edge. Continue to enhance the degree of automation in your production. Explore tailor-made solutions from TRUMPF designed to perfectly suit your company's needs. Together we will take your Smart Factory to a new level!

Find the solution that's right for you!

Find your tailor-made solution!

Find the perfect TRUMPF solution for your production process. You can discover the ideal manufacturing solution by answering three simple questions. Give it a try, then contact our Smart Factory consultants to discuss the result.

Connected, intelligent, efficient

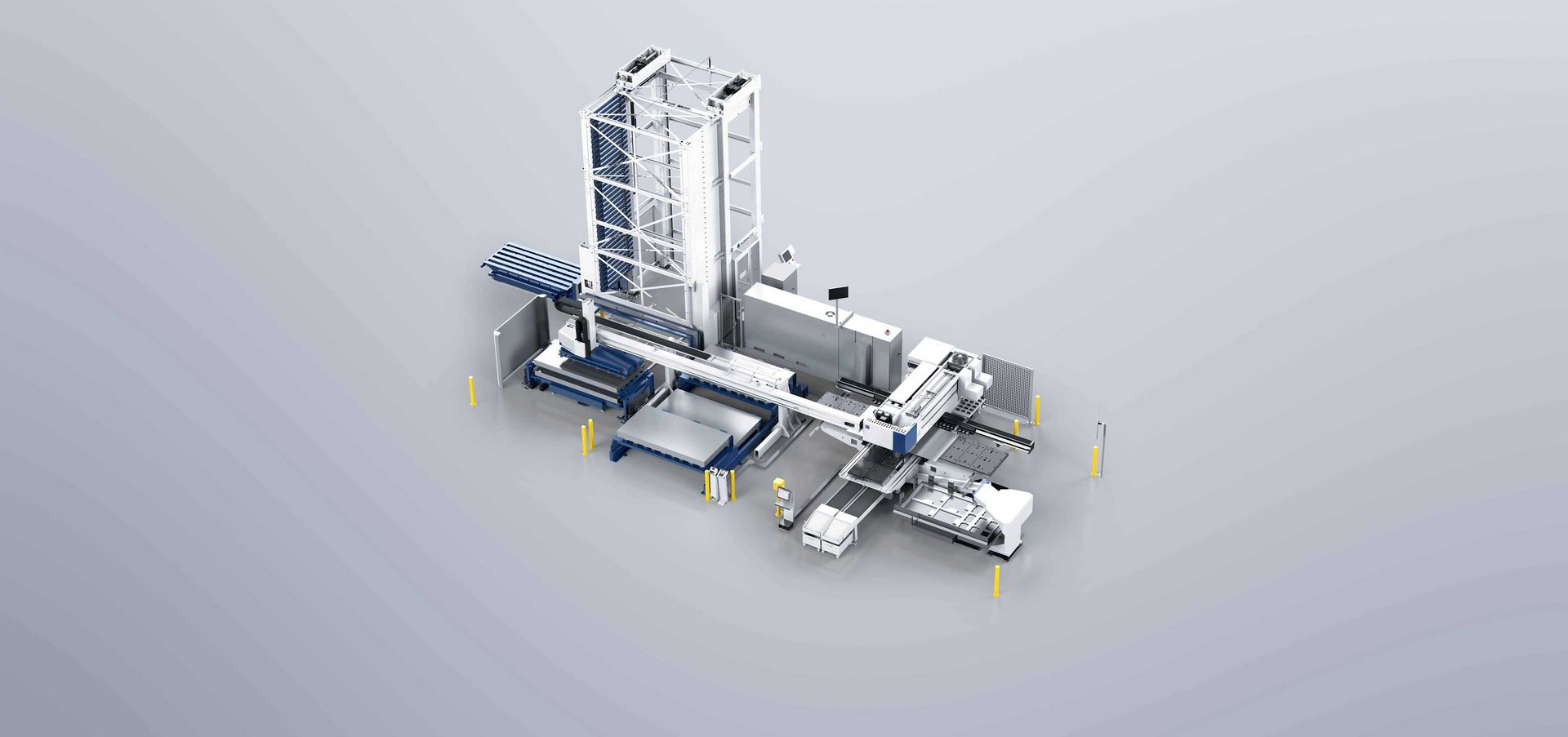

Unique manufacturing, customised solutions. Our seasoned Smart Factory experts collaborate with you to create the perfect plan for your transition to a Smart Factory. Here is an example of how you can adapt your Smart Factory step by step:

1. Optimum loading and unloading

The SheetMaster enables you to load and unload your punching or punch laser machine and sort parts reliably. The sheets or blanks are lifted from the sheet station using suction cups and transported to the machine table. By using various suction cups, you can process an extensive variety of applications, depending on the machine type.

2. Supporting and optimising material flow

The dual cart allows front loading and unloading, and supports the material flow from one side to the other.

3. Automatically dispose of scrap skeletons

The GripMaster ensures convenient scrap skeleton handling on the TruPunch punching machines and TruMatic punch laser machines. The automatic unloading process increases the machine runtime, speeds up job processing and increases occupational safety.

4. Flexible and scratch-free production

The TruMatic 7000 combines the advantages of punch and laser processing in a particularly cost-efficient way. It also meets high demands as regards part quality, productivity and flexibility.

5. Remain flexible in the long term

The modular TruStore 3030 compact store with short material change cycles helps to boost your flexibility and productivity. It grows dynamically to meet your requirements, reduces space needs and can be expanded into a fully automated system.

Find your tailor-made solution!

Find the perfect TRUMPF solution for your production process. You can discover the ideal manufacturing solution by answering three simple questions. Give it a try, then contact our Smart Factory consultants to discuss the result.

Request consultation

Would you prefer to schedule a consultation directly? In our consulting service, you will work with one of our Smart Factory experts to find the optimal solution for increasing the level of automation in your production.