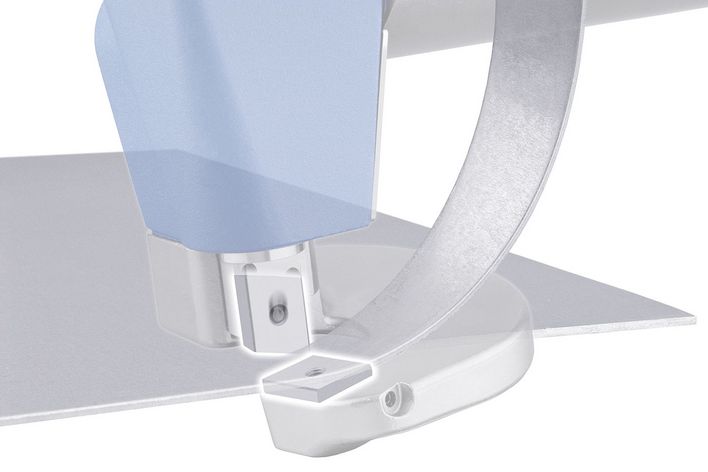

The shear principle allows deformation of the material, but no material is lost in the form of scrap chips. When cutting with the sheet metal cutters ,the upper moving cutter blade moves against the fixed lower cutting table blade. This puts high tension on the material to be machined and creates what is known as a lead crack. With sheet metal cutters, the material is sheared off at a high cutting speed and the cutting table blade absorbs the entire shear force of the moving cutter blade.

Advantages

- Excellent performance on curves

- Quick, precise cutting

- Long tool life

- Chip-free cutting

- Great cut quality