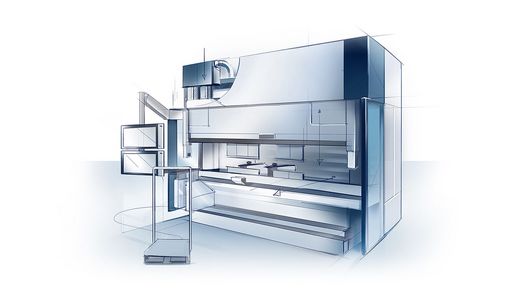

Less set up, more bending

The TecZone Bend programming system creates the programs for your bending parts. The Tool Setup Optimizer option checks which parts you need the same tools for and how the tool stations can be best combined. This enables you to bend the maximum number of parts with only one tool setup.