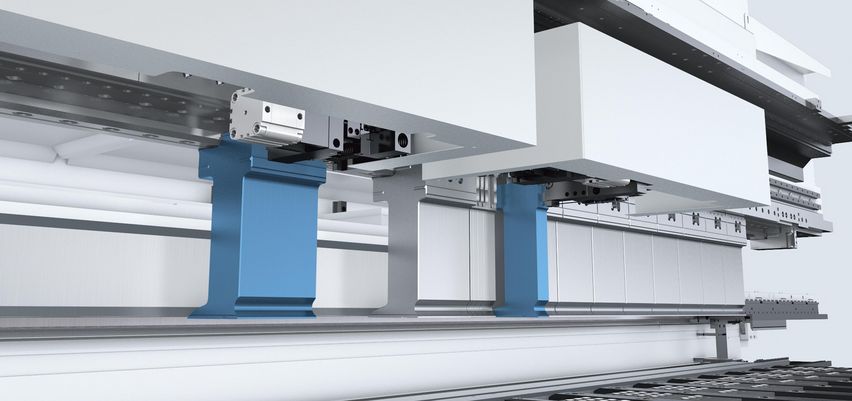

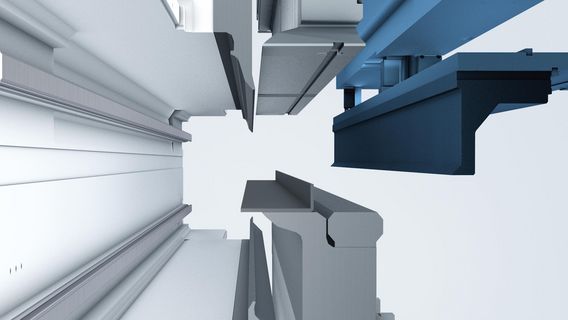

With its ingeniously simple continuous path control, the innovative angle drive of the TruBend Center ensures maximum accuracy. The interaction between two axes provides the ideal traverse path to protect the surface of your component. The drive design also makes your TruBend Center particularly robust for everyday industrial applications.

Semi-automatic panel bender

The TruBend Center 5030 sets the standard when it comes to flexibility during panel bending. Discover what is arguably the widest range of parts in this machinery category with the semi-automatic TruBend Center 5030. Going far beyond the classic panel bending range, you can also process complex workpieces quickly and flexibly. Produce components for an array of industrial purposes and applications, from delicate shrouds up to large-scale trays.

The 2-axis part manipulator positions the sheet metal and even enables negative bends.

Simple offline programming with TecZone Fold.

First part, perfect part – thanks to ACB laser.

Set up the right blank holder tools automatically with the integrated tool changer ToolMaster Bend.

Various gripper systems help to hold the components.

The on-demand servo drive works quickly, quietly and in an energy-efficient way.

Mild steel drawer, sheet thickness 0.6 mm

High repeatability for different bends.

Mild steel housing cover

Maximum accuracy, even in thicker materials.

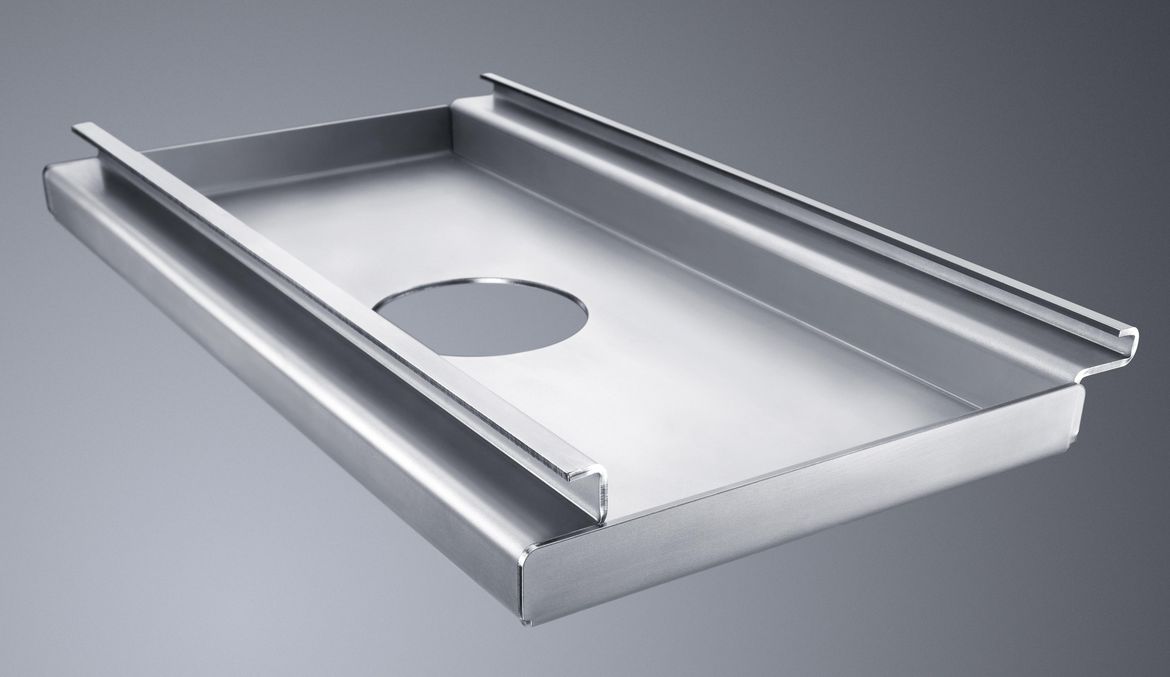

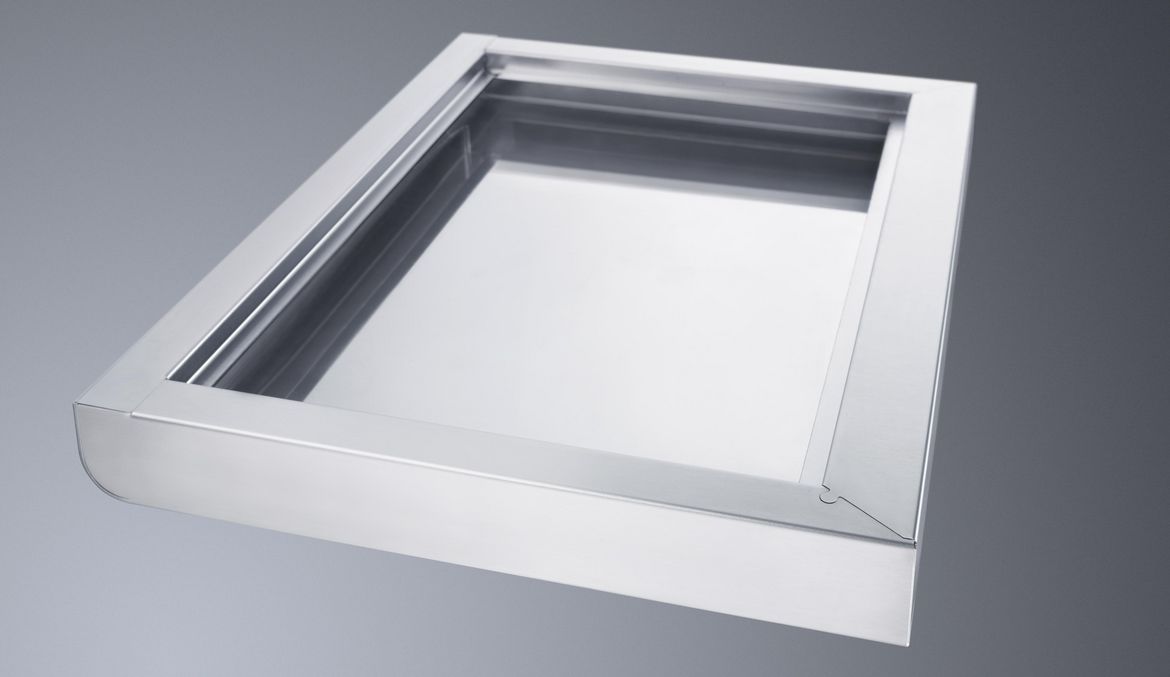

Stainless steel drawer

Radius bending with double sheet.

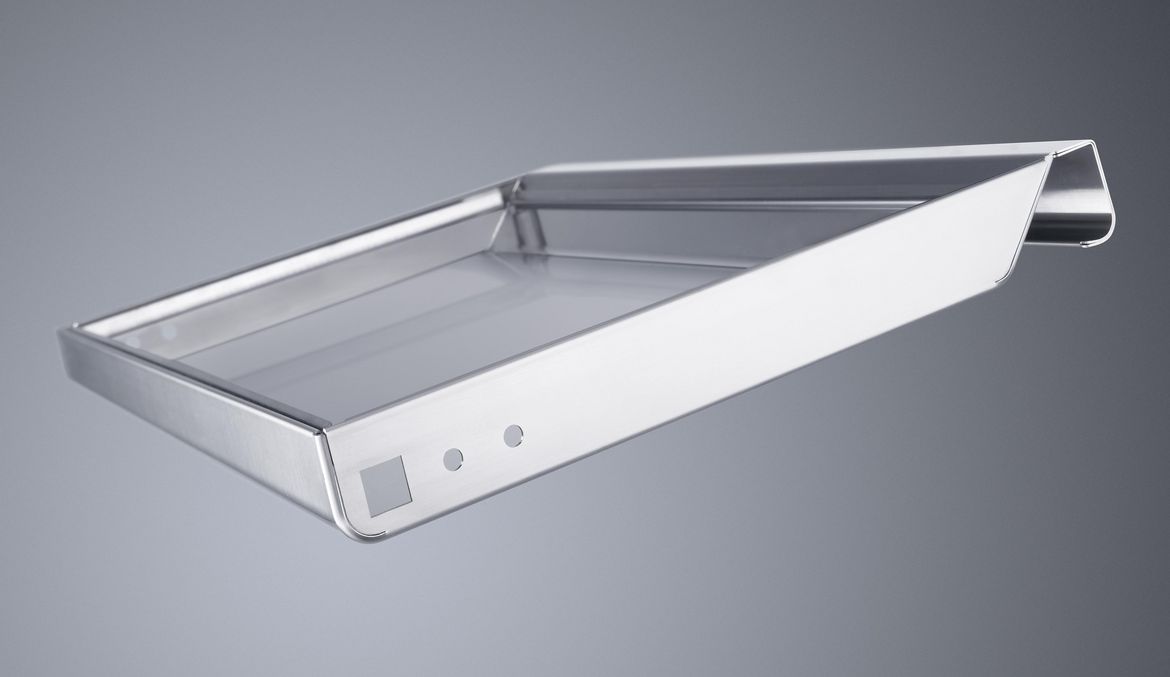

Stainless steel screen trim

Short sides combined with radius bending.

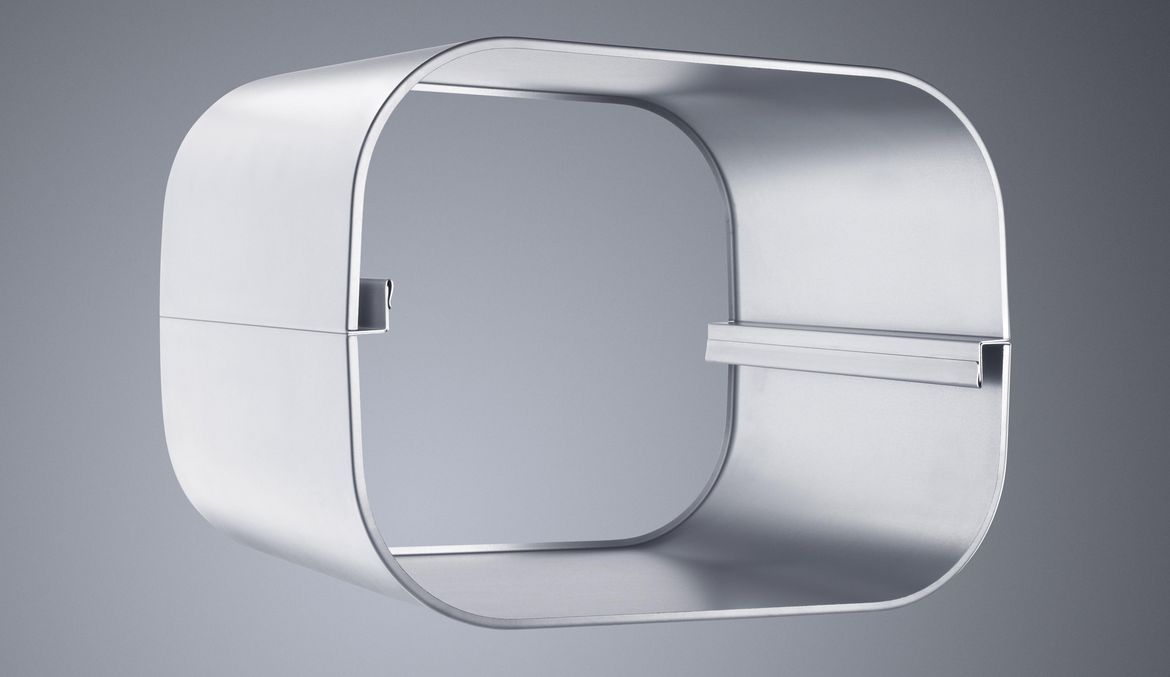

Mild steel container

Maximum accuracy during production.

Mild steel guard plate

High repetition accuracy for a variety of bends.

|

TruBend Center 5030

|

|

|---|---|

| Maximum bending length | 3123 mm |

| Minimum bending length | 80 mm |

| Maximum box height | 220 mm |

The technical data of all product versions as a download.

Numerous functions ensure the TruBend Center 5030 is precise and productive.

ACB laser is an optical bending angle correction system that operates without contact: a laser projects a line onto the sheet, and a camera then detects the angle.

The 3-surface suction module positions the sheet using suction cups on the front face, top and bottom. If there is an insufficient suction area, magnetic or gripper modules take on this task.

For components with an insufficient suction area, other gripper systems take over the positioning of the sheet. So-called magnetic or gripper modules are used for these generally smaller components.

You can call up the right bending programme in an instant using the 2D code scanner or a Bluetooth scanner. The 2D code scanner is connected to the machine, reads a bar code or Data Matrix Code from the paper, and automatically loads the programme; the Bluetooth scanner can even scan the sheet metal.

Program parallel to production and produce without paper – the additional monitor on the machine control shows you further information in addition to the required screens and drawings for programming and production. This allows you to program and produce at the same time by using shop floor programming, for example.

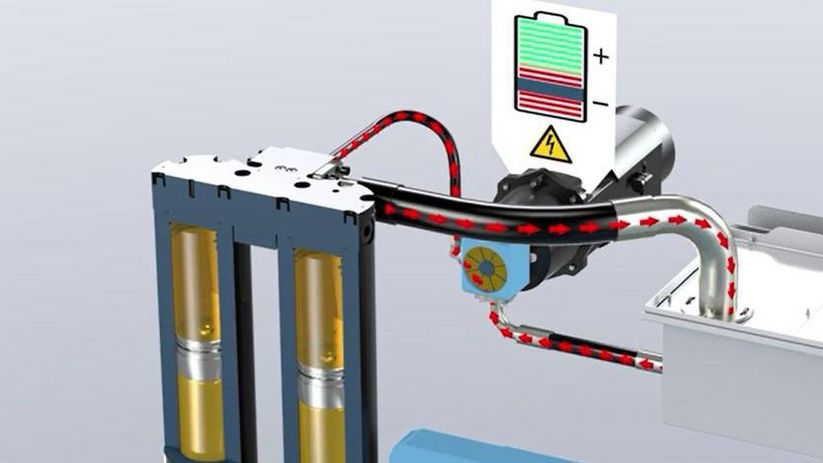

The on-demand servo drive supplies your TruBend machine with precisely the amount of energy needed. It only runs during the bending process; otherwise the hydraulic system is stationary and does not use any energy. If the press beam has to overcome a large pressing depth, it supports it with increased working speed. The drive operates economically, quickly and extremely quietly.

Seamless integration of many TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

TecZone Fold

Save yourself time and increase quality during the automatic creation of your programmes on the basis of 2D or 3D data. Using TecZone Fold, the programming system for the automatic offline programming of TruBend Center panel benders.

Software

The software portfolio from TRUMPF optimises your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customised Industry 4.0 solutions for your Smart Factory.

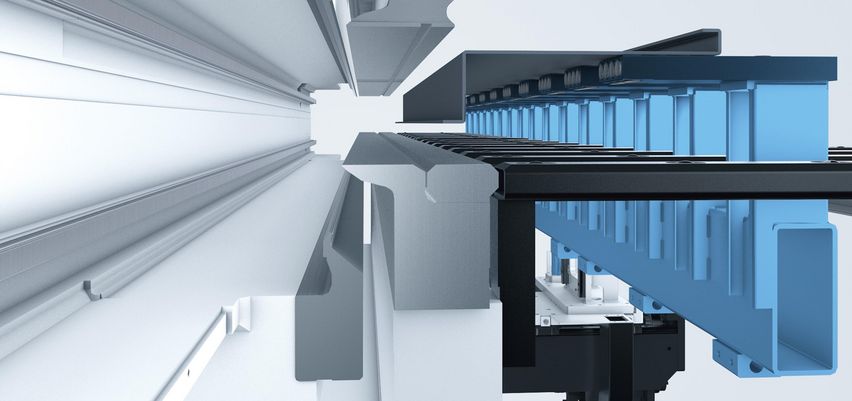

With additional blank holders, you can also produce very narrow profiles or components with formed sections near the bending lines. If required, the machine automatically swivels in the ENW extra blank holder tool from above. The available standard blank holders do not need to be replaced or modified for this.

Extra bending tools can be set up automatically in order to bend flanges or offset bends. When needed, the tools move automatically to the correct position from their parking position on the side, and process the sheet without the use of the remaining bending tools.

You can easily produce nestings with inner edges thanks to the horn blank holders. The "horns" extend and retract automatically at an angle. This means that the blank holder can move downwards without causing a collision between the tool and the bend.

More bending freedom: Benefit from our comprehensive range of bending tools or have special tools created to your requirements.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.