The BendMaster can handle a load of 60 kg.

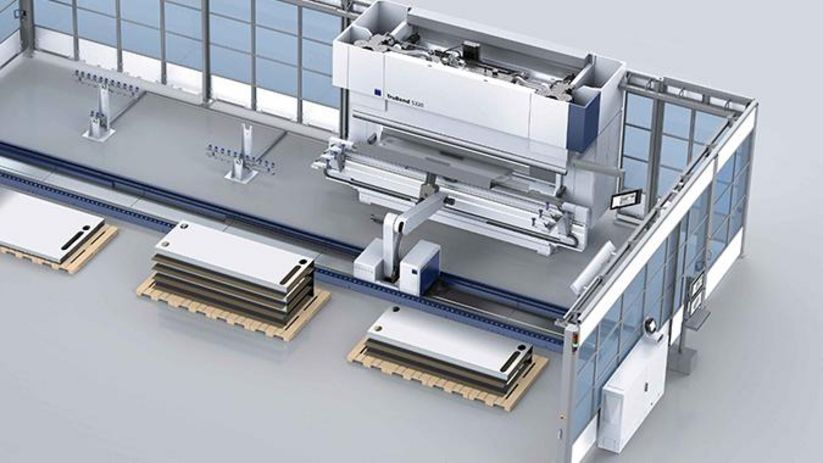

Cost-effective productive bending cell

The TruBend Cell 5000 Lean Edition is programmed in no time for fast, precise bends. It is the ideal solution for productive and flexible automation for a wide variety of parts. Achieve high-quality bends with ease, thanks to intuitive programming and straightforward gripper changes.

The TecZone Bend programming system is extremely fast and easy to use.

You can bend small and medium-sized parts, as well as parts weighing up to 40 kg, thanks to the combination of gripper and vacuum gripping technology.

The automatic gripper change saves you time.

A sheet sensor helps the gripper to pick up the blanks correctly.

Multigripper medium on the TruBend Cell 5000 Lean Edition

Grippers with vacuum technology make part handling much easier.

Pivoting-jaw gripper on the TruBend Cell 5000 Lean Edition

The pivoting-jaw gripper helps to bend small parts automatically. The linear and rotary axes reduce time-consuming regripping.

Multigripper small on the TruBend Cell 5000 Lean Edition

The adjustable multigripper small is suitable for smaller parts. Quick-release fasteners enable you to adjust it to the part in a few simple steps. With its 180-degree rotation unit, it also significantly reduces valuable cycle time when bending nests.

|

TruBend Cell 5000 Lean Edition

|

|

|---|---|

| Machine | |

| Press force | 850 kN |

| Bending length | 2210 mm |

| Width between columns | 1750 mm |

| Usable open height | 615 mm |

| Throat depth | 420 mm |

| Speeds | |

| Rapid downward movement | 220 mm/s |

| Maximum Y press operation | 10 mm/s |

| BendMaster (60) | |

| Maximum carrying capacity | 60 kg |

| Maximum sheet weight | 40 kg |

| Maximum blank dimension | 1000 mm x 2000 mm |

| Minimum sheet thickness | 0.7 mm |

| Dimensions and weights | |

| Weight, basic machine | 8300 kg |

| TruBend machine | 3020 mm x 1800 mm x 2840 mm |

The technical data of all product versions as a download.

The small parts package consists of a sheet removal station and a pivoting-jaw gripper. The sheet removal station separates and produces parts parallel to production in a single operation. The pivoting-jaw gripper enables the automated bending of small parts. Its linear and rotary axes reduce time-consuming regripping.

The adjustable multigripper makes time-consuming gripper construction a thing of the past. You can configure your gripper in the TRUMPF offline programming system in just a few minutes. With a few simple manual moves, you can adapt your multigripper to the part geometry with the help of the setup plan. You benefit from a substantial reduction in non-productive time. This frees up time for your skilled workers to generate additional value.

The console swaps grippers automatically and can complete orders without the need for manual intervention.

TecZone Bend

With TecZone Bend, you can program faster than ever as the software creates a program suggestion in a few seconds based on 2D and 3D data – including NC program.

Software

The software portfolio from TRUMPF optimises your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customised Industry 4.0 solutions for your Smart Factory.

You can choose between more than 150 upper and lower tool types for your personal range. You can order tools individually or as a set.

During the processing of galvanised sheets, even after just a few bends, there may be zinc deposits on the die, resulting in cold welding. This can lead to imprints on the component and imprecision. This can be avoided with the coated LASERdur ZN TRUMPF bending tools. These combine a high level of surface hardness with excellent sliding properties, are corrosion-resistant and do not require cleaning.

For specific requirements, TRUMPF will develop your own personal tool solution. To guarantee the quality of your parts, we test the tools in advance with your specific material and create initial sample parts.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.