With the TruBend Series 8000 you can bend oversize-format components particularly quickly and efficiently. Thanks to numerous automation functions, the machine is also ideal for your Smart Factory.

Flexible large-format machine

The machines in the TruBend Series 8000 impress with their precise versatility, a usable open height of up to 875 mm, large throat depths and a maximum press force of 1,000 tons. You can process particularly large and heavy parts up to a length of 8 m. You can also bend smaller workpieces at several tool stations. Innovative characteristics such as lower tool displacement, CNC-controlled crowning and the 6-axis backgauge provide you with complete application freedom. The work of the operator is made easier thanks to numerous options such as the angle measuring system, the control – which is simple and intuitive to use – as well as clever ergonomic solutions such as the ToolShuttle.

875 mm open height, 620 mm throat depth, 1,000 t press force and 8 m bending length

The crowning and tool clamps have a load capacity of up to 6,000 kN per metre.

With the multi-touch control, operation is as easy and intuitive as with a standard tablet PC.

Numerous equipment options make production more enjoyable, safer and more productive.

The LCB system measures angles without contact, without wear and independent of the tool.

Surface-mounted versions up to 6 m save expensive foundations.

The 6-axis backgauge provides you with complete production freedom.

Simple setup for heavy tools; space-saving storage at the machine.

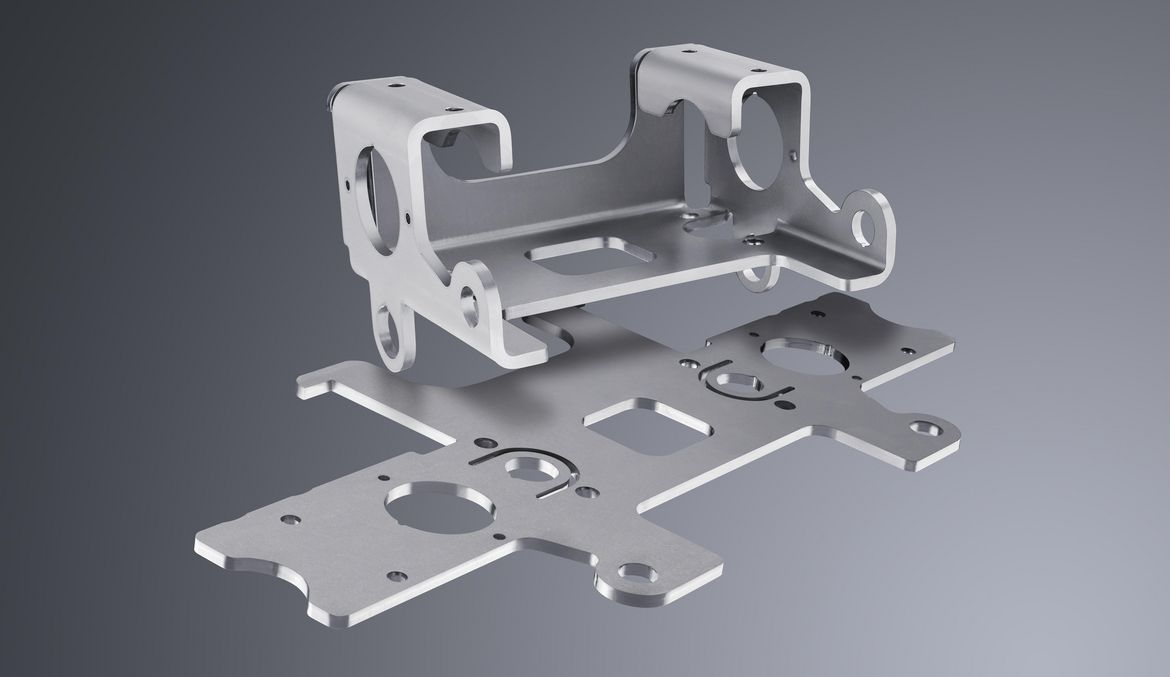

The TruBend press brakes are so flexible that you can use them to solve the most varied tasks

Whether for large or small, complex or simple components – our patented technology ensures that the bending angle is correct right from the start.

The TruBend Series 8000 also achieves high angular accuracy in thick sheet parts.

The TruBend Series 8000 even bends long profiles in a straight line with a high level of angular accuracy.

The TruBend Series 8000 easily processes thick sheet parts – even step bends.

Whether for large or small, complex or simple components – our patented technology ensures that the bending angle is correct right from the start.

Whether for large or small, thick or thin, complex or simple components – the TruBend Series 8000 ensures that the bending angle is right from the very beginning.

The TruBend Series 8000 also achieves high angular accuracy in thick sheet parts.

Easily process thick sheet parts with the TruBend Series 8000 – even high-tensile materials are easy to bend.

The TruBend Series 8000 even bends long profiles in a straight line with a high level of angular accuracy

Oversize format processing: The TruLaser Series 8000 enables you to laser cut sheet metal with a length of up to 16 metres. With the TruBend Series 8000 you can bend parts up to 8 metres, or even 16 metres in tandem operation.

|

TruBend 8400 (5 m)

Compare product

|

TruBend 8400 (6 m)

Compare product

|

TruBend 8500 (4 m)

Compare product

|

TruBend 8600 (5 m)

Compare product

|

TruBend 8600 (6 m)

Compare product

|

TruBend 8800 (6 m)

Compare product

|

TruBend 8800 (7 m)

Compare product

|

TruBend 8800 (8 m)

Compare product

|

TruBend 81000 (7 m)

Compare product

|

TruBend 81000 (8 m)

Compare product

|

|

|---|---|---|---|---|---|---|---|---|---|---|

| Press force | 4000 kN | 4000 kN | 5000 kN | 6000 kN | 6000 kN | 8000 kN | 8000 kN | 8000 kN | 10000 kN | 10000 kN |

| Bending length | 5050 mm | 6050 mm | 4050 mm | 5050 mm | 6050 mm | 6050 mm | 7050 mm | 8050 mm | 7050 mm | 8050 mm |

| Width between columns | 4050 mm | 5050 mm | 3050 mm | 4050 mm | 5050 mm | 5050 mm | 6050 mm | 7050 mm | 6050 mm | 7050 mm |

| Usable open height for TRUMPF tool systems | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm |

| Throat depth | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm |

| User interface | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control |

| Maximum speed Y axis, operation | 10 mm/s | 10 mm/s | 10 mm/s | 9 mm/s | 9 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 8 mm/s | 8 mm/s |

| Dimensions, weights | ||||||||||

| Length | 6100 mm | 7280 mm | 5280 mm | 6280 mm | 7280 mm | 7280 mm | 8280 mm | 9280 mm | 8280 mm | 9280 mm |

| Width | 2160 mm | 2160 mm | 2720 mm | 2720 mm | 2720 mm | 2760 mm | 2760 mm | 2760 mm | 2910 mm | 2910 mm |

| Height | 4020 mm | 4320 mm | 4070 mm | 4170 mm | 4470 mm | 4570 mm | 4570 mm | 4770 mm | 4750 mm | 4850 mm |

| Weight | 34000 kg | 39000 kg | 37600 kg | 51000 kg | 55000 kg | 70000 kg | 80000 kg | 85000 kg | 90000 kg | 102000 kg |

|

TruBend 8400 (5 m)

|

TruBend 8400 (6 m)

|

TruBend 8500 (4 m)

|

TruBend 8600 (5 m)

|

TruBend 8600 (6 m)

|

TruBend 8800 (6 m)

|

TruBend 8800 (7 m)

|

TruBend 8800 (8 m)

|

TruBend 81000 (7 m)

|

TruBend 81000 (8 m)

|

|

|---|---|---|---|---|---|---|---|---|---|---|

| Press force | 4000 kN | 4000 kN | 5000 kN | 6000 kN | 6000 kN | 8000 kN | 8000 kN | 8000 kN | 10000 kN | 10000 kN |

| Bending length | 5050 mm | 6050 mm | 4050 mm | 5050 mm | 6050 mm | 6050 mm | 7050 mm | 8050 mm | 7050 mm | 8050 mm |

| Width between columns | 4050 mm | 5050 mm | 3050 mm | 4050 mm | 5050 mm | 5050 mm | 6050 mm | 7050 mm | 6050 mm | 7050 mm |

| Usable open height for TRUMPF tool systems | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm | 675 mm |

| Throat depth | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm | 420 mm |

| User interface | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control | T8000T multi-touch control |

| Maximum speed Y axis, operation | 10 mm/s | 10 mm/s | 10 mm/s | 9 mm/s | 9 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 8 mm/s | 8 mm/s |

| Dimensions, weights | ||||||||||

| Length | 6100 mm | 7280 mm | 5280 mm | 6280 mm | 7280 mm | 7280 mm | 8280 mm | 9280 mm | 8280 mm | 9280 mm |

| Width | 2160 mm | 2160 mm | 2720 mm | 2720 mm | 2720 mm | 2760 mm | 2760 mm | 2760 mm | 2910 mm | 2910 mm |

| Height | 4020 mm | 4320 mm | 4070 mm | 4170 mm | 4470 mm | 4570 mm | 4570 mm | 4770 mm | 4750 mm | 4850 mm |

| Weight | 34000 kg | 39000 kg | 37600 kg | 51000 kg | 55000 kg | 70000 kg | 80000 kg | 85000 kg | 90000 kg | 102000 kg |

The technical data of all product versions as a download.

Numerous functions make working with the TruBend Series 8000 even safer, easier, more ergonomic and more productive.

Precision combined with productivity

The LCB (Laser Controlled Bending) optical angle measuring system ensures precise angles from the first part. LCB measures an angle without contact and without wear by using a laser which projects a line onto the sheet and a camera which detects the angle. This decreases material costs and increases productivity. The system, which operates irrespective of the tool, does not require any setup time and is easy to use.

You are equipped for almost any eventuality with up to 6 CNC-controlled backgauge axes. Your workpieces are positioned precisely and securely – for perfect bending results.

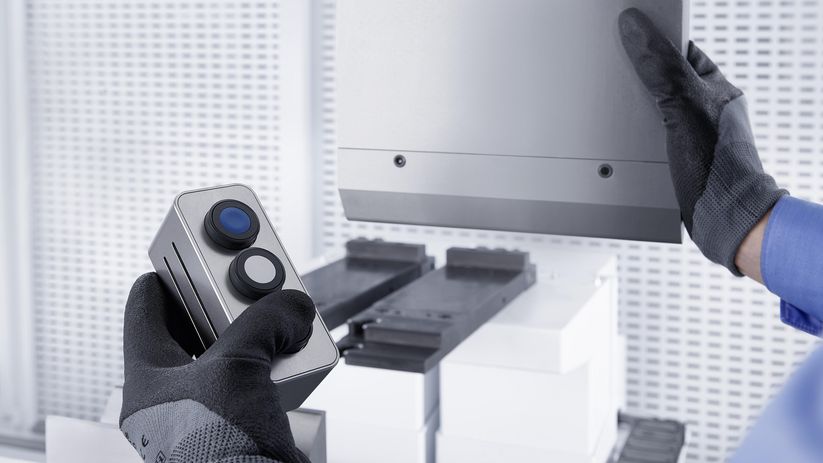

MobileControl, the handy mobile control unit, can be flexibly attached to metallic surfaces, such as the press beam, with magnets. This means the most important functions are always at hand and travel is reduced.

The automatic crowning is sophisticated right up to the last detail. You can adjust the crowning curve optimally to your bending task every 250 mm. The crowning facility has a load capacity of up to 6,000 kN/m.

Seamless integration of many TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

Ergonomics

The practical bending aid including automatic height adjustment provides valuable help – in particular when bending heavy or large parts. It has a load capacity of up to 300 kg.

Support brackets which can be variably adjusted in their height make component handling easier. The robust support brackets each have a load capacity of up to 300 kg and are available with different supports.

Flexibility

With the lower tool displacement you can perform two different bending operations with one tool. This increases part variety whilst also saving setup time and investment costs. The lower tool displacement enables special applications such as folding to be produced productively.

TruTops Boost

Program your bending machines intelligently using TruTops Boost, the all-in-one solution for 3D design. Numerous automated processes save you time-consuming routine processes. You also profit from a comprehensive ruleset with the bundled technical expertise of TRUMPF.

TecZone Bend

Program faster than ever before: with TecZone Bend you can combine bend programming in the office with shop floor programming at the TruBend bending machine. A program suggestion is automatically created in a few seconds based on 2D and 3D data – including NC program.

Software

The software portfolio from TRUMPF optimises your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customised Industry 4.0 solutions for your Smart Factory.

ToolShuttle, the practical tool magazine, stands directly next to your TruBend Series 8000 machine. During setup, tools are simply slid in and out of the machine, something that is particularly useful for heavy tools, saving time. The ToolShuttle has space for nearly 60 m of tools and ensures everything is organised.

You can choose between more than 150 upper and lower tool types for your personal range. You can order tools individually or as a set.

During the processing of galvanised sheets, even after just a few bends, there may be zinc deposits on the die, resulting in cold welding. This can lead to imprints on the component and imprecision. This can be avoided with the TRUMPF LASERdur ZN bending tools. These combine a high level of surface hardness with excellent sliding properties, are corrosion resistant and do not need to be cleaned.

For specific requirements, TRUMPF will develop your own personal tool solutions. To guarantee the quality of your parts, we test the tools in advance with your specific material and create initial sample parts.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.