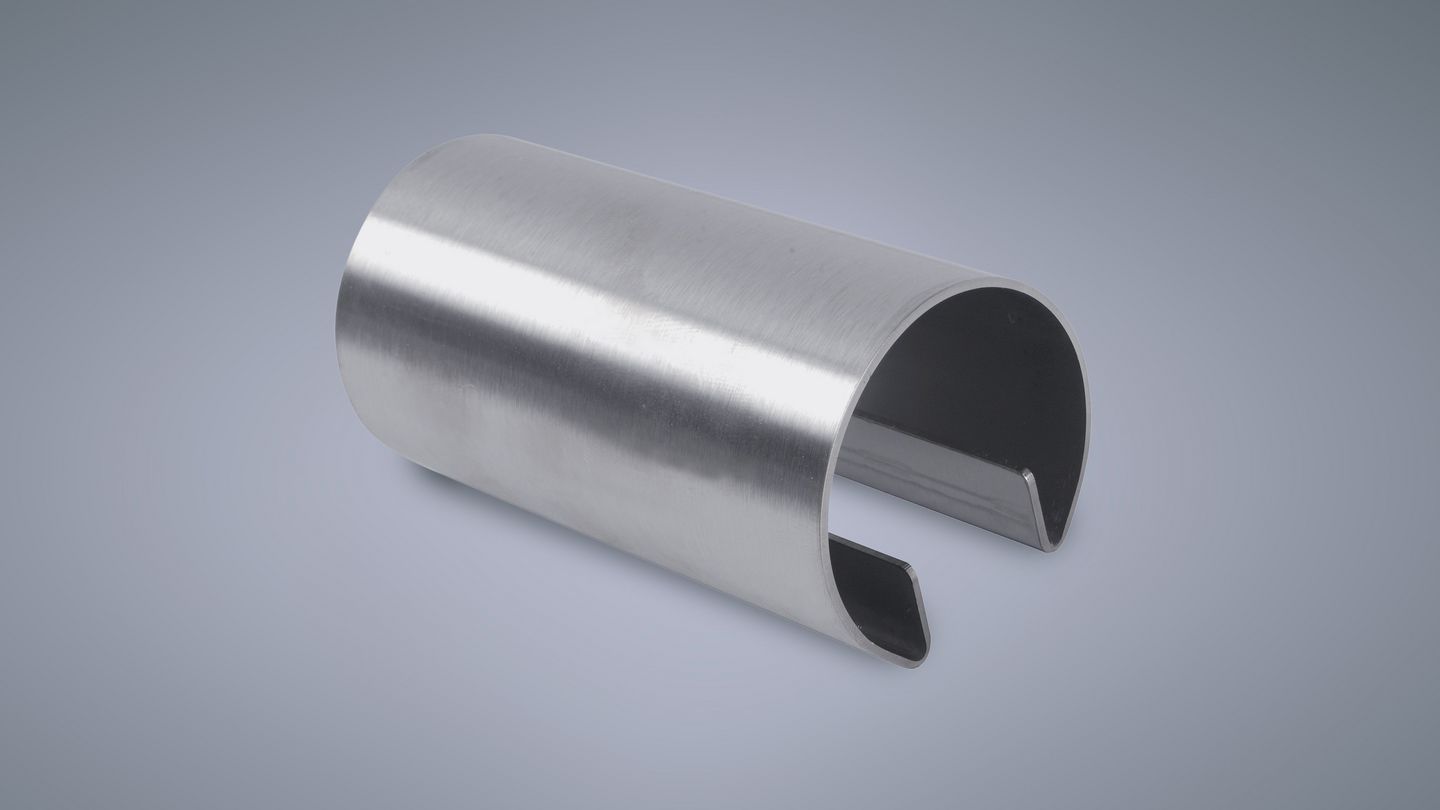

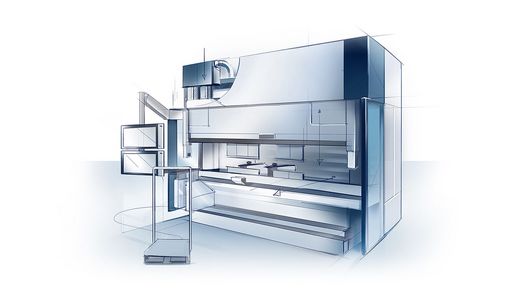

Standard tools

You can order all TRUMPF bending tools as a set or individually. With more than 150 various upper and lower tool versions in stock, plenty of part geometries are possible. The Data Matrix Code enables simple scanning and therefore makes it possible to automatically load the tools into the control.