The bending process offers sheet metal processing companies enormous potential to boost their productivity. Currently, only around 10% of all bending machines worldwide are automated. New developments in this area enable significant efficiency increases. This is where TRUMPF's solutions come in. Digitalization, automation, and AI-powered programming are taking bending productivity to a new level.

TruBend 3000: 40% less throughput time

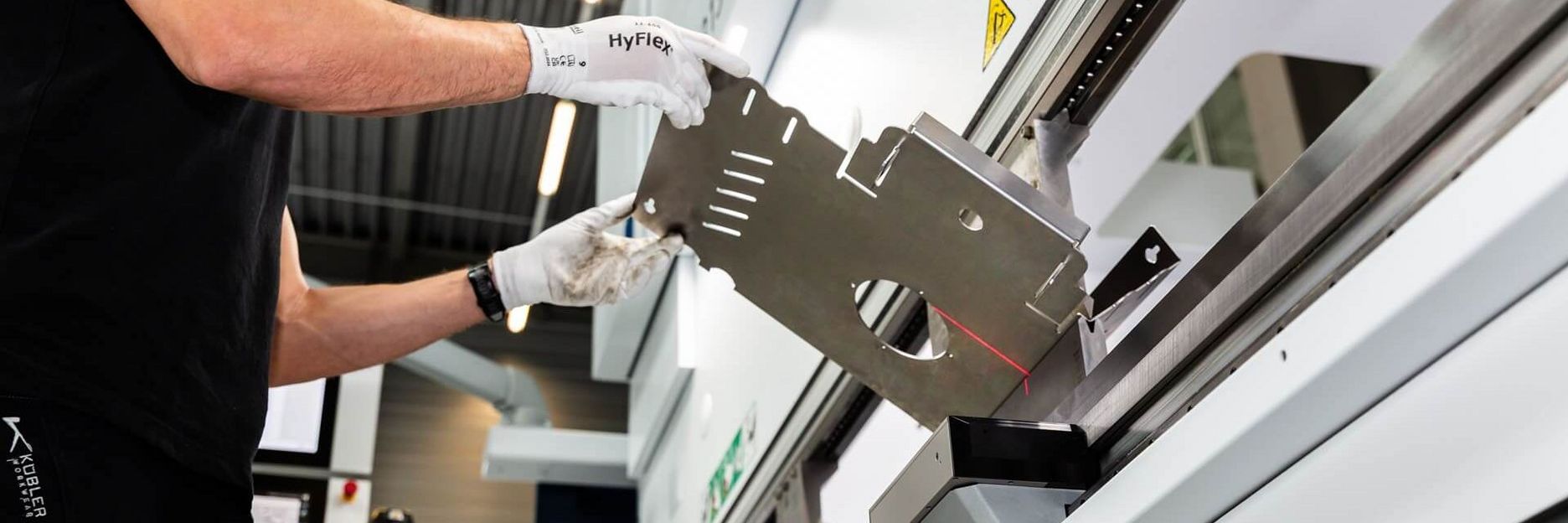

A highlight at the TRUMPF stand is the new TruBend 3000 generation of bending machines. This machine works extremely quickly and precisely, is intuitive to program and saves energy. Various technologies that TRUMPF has already established in the premium TruBend 5000 series enable a 40% reduction in throughput time compared to the previous model and greater part precision.

Flex Cell: Mobile bending cell with AI programming

TRUMPF also presents the "Flex Cell" mobile bending cell in combination with the TecZone Bend software. The AI-based software takes over the programming of the robot and the machine, reducing the required from up to two hours to just a few seconds. In addition, TRUMPF has optimised the interaction between the robot and the bending machine. This results in a 30% time saving per bend for the user.

TruBend Center 7030: 30% faster

A new swivel bending machine, the TruBend Center 7030, is also one of the highlights at the TRUMPF stand. It works 30% faster than its predecessor. This is possible because the automation handles the component much closer to the bending line than in the previous model. This saves users a lot of time, especially when there are multiple bends.

Lower production costs due to to fibre lasers

All machines exhibited by TRUMPF at the Blechexpo are equipped with the latest generation of fibre lasers. These have a smaller installation area, enabling more compact machines. In addition, fibre lasers are extremely energy-efficient and low-maintenance, which reduces operating costs for the user.