When Robert Bloos climbs into the excavator in the morning sun, industrial innovation begins – in practice, not in the conference room. Bloos is serious. He pitches in because he knows that change begins with attitude. The managing director of Heizomat, a family-run medium-sized company based in Gunzenhausen, builds heating systems that run on wood chips – robust, carbon neutral and independent of fossil fuels. For decades, the company has supplied farmers, municipalities and businesses that rely on renewable heat. But that's no longer enough for Bloos.

He aims to show that sustainable industrial production can also be economically viable. In Heidenheim, just a few kilometers from its headquarters, Heizomat is building a model factory – the GreenSmart Factory. Not an image project, but a fully-fledged production site that aims to set standards – in energy self-sufficiency, digitalization and sustainable industrial production.

Together with technology partner TRUMPF, Heizomat has reimagined and implemented the entire manufacturing process. The partnership combines the best of both worlds: cutting-edge technology and attitude. Bloos has long been thinking beyond his traditional customer base. The new factory is intended not only to appeal to farmers and local authorities, but also to industrial customers looking for independent, tried-and-tested energy systems.

Because Heizomat wants to move out of its niche. Over the years, the company has earned an excellent reputation for its wood chip heating systems – for quality, durability and practicality. Now Bloos is taking the next step. By building the Green Smart Factory, he wants to show how medium-sized businesses, sustainability and intelligent networking can work together.

Going all in

Robert Bloos knows that industrial manufacturers need planning security. Few dare to switch to a new energy supply until it has been tried and tested in practice. So he is taking the lead and setting himself up as a functioning role model. The Green Smart Factory proves that energy-autonomous industrial production is technically possible and also economically viable. Heizomat is moving its entire sheet metal, round tube and machining process into the building and demonstrating how sustainability and economic efficiency can be combined – with digitalization as the key technology.

"Three things define the Green Smart Factory," says Bloos. "The energy supply, state-of-the-art machinery and the software that ties it all together. The whole thing follows a simple guiding principle whereby production is based on the available energy – not the other way around. Bloos calls this "energy-driven".

Heizomat provides

Specifically, it works like this: sun, wind and wood cover the entire energy requirement. Coupled systems supply the production hall with electricity, heat and even cooling. The heart of Heizomat is a high-performance wood chip heating system combined with a wood gasifier. This not only generates heat, but also valuable electricity around the clock. Heizomat produces the required wood chips itself. A pallet chipper breaks down on-site the pallets used by suppliers to deliver items like sheet metal. This apparent waste is transformed into a valuable energy source that supplies production with sustainable heat.

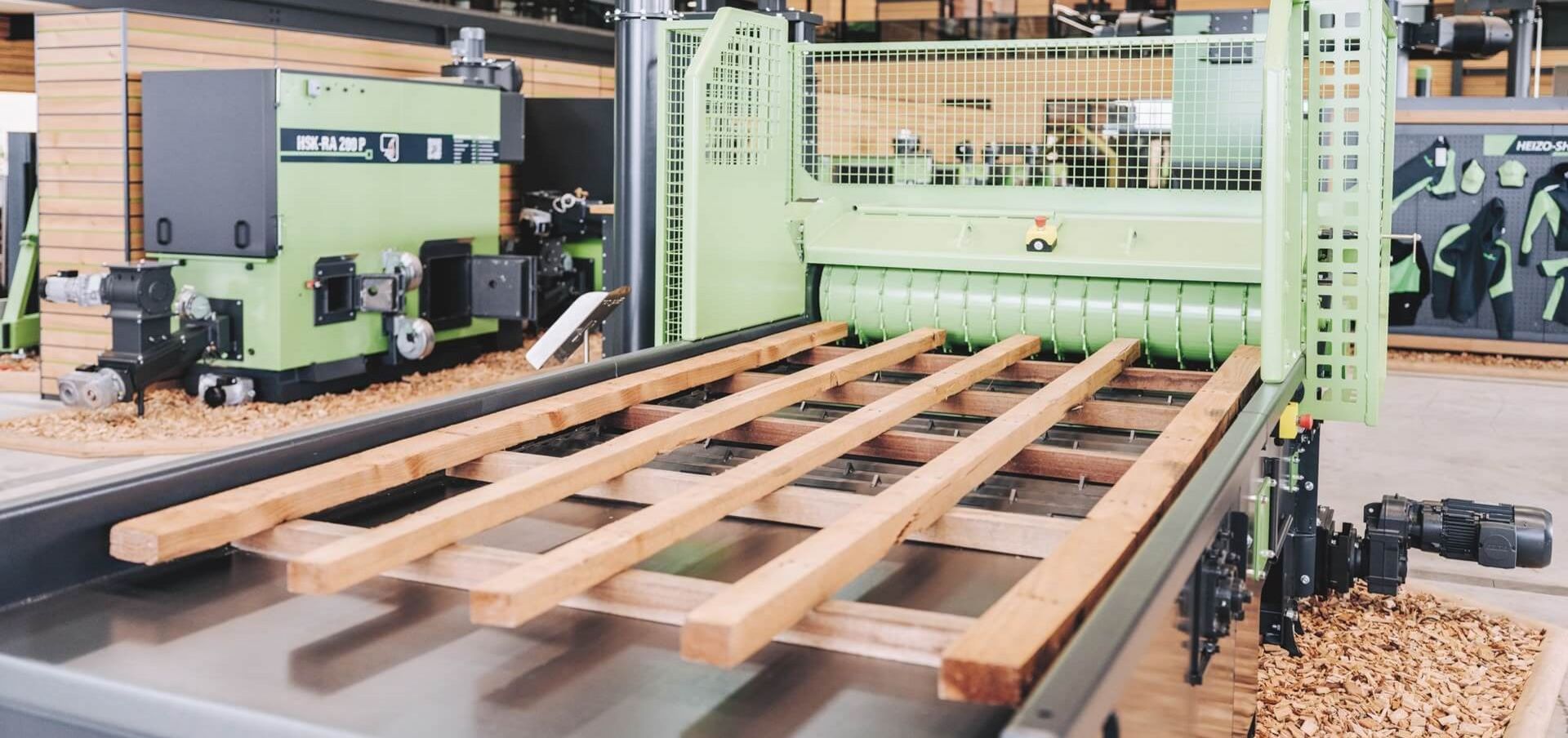

Heizomat has also thought of every detail. The hall features an impressive, highly efficient heat distribution system with integrated lighting. This is also part of the concept: not just shifting resource consumption, but reducing it. But the building continues to "think". The manufacturing process is automated, and the control system is intelligently networked. Heizomat planned the machinery in conjunction with TRUMPF. It includes several welding cells from the TruArc Weld 1000 series, bending machines from the TruBend 5000 and 8000 series and laser cutting machines such as the TruLaser 3030 and the TruLaser 5040, as well as the STOPA large-scale storage system. All of this can be planned and controlled via theTRUMPF Software Oseon, which communicates seamlessly with the company's own ERP system, a software that controls business processes. Material, data and energy flow together – intelligently, efficiently, and continuously.

For the other six partner companies – ranging from energy and building technology to automation solutions – the Green Smart Factory is a real stroke of luck. They are able to use the production hall as a showroom to demonstrate real production processes to their customers. Bloos emphasises that this is an invaluable advantage, especially in times of digitally networked manufacturing. "Most companies have so far only shown their customers individual machines. But the crucial thing is how everything works together."

For Robert Bloos, this work is far more than a showcase – it is a strategic necessity. Anyone who wants to be independent today needs to be prepared. That is why Heizomat stocks up, with enough wood chip or over a year, along with large quantities of sheet metal. As much as possible is done in-house – as a matter of principle. Because security is not a result of words or declarations of intent, but of actions. "The farmer harvests enough wood for two years and stores it in the yard. We think in this way, too," says Bloos.

This attitude is also reflected in the financing of the new factory. Bloos avoided the risks of external capital by relying on its strong reserves. When others stumble in times of crisis, Heizomat remains stable because Bloos and his team take deliberate precautions. At the same time, the company practises a genuine circular economy. The wood chips come from the local region – often from trees that have to be felled anyway and are located near motorways. What is considered waste elsewhere, Heizomat uses as a valuable resource. And the result remains in the region, with short distances, clear responsibilities and a strong identity.

The machinery is not a product of chance. The close partnership with TRUMPF has one clear goal – to increase productivity and reduce workload. Tedious jobs like manually bending sheet metal parts are a thing of the past. The machines integrate seamlessly into the overall digital concept. What used to be documented on paper is now automated – controlled, documented, analysed.

Innovation through action

At Heizomat, new solutions are not created on the drawing board. Bloos listens, trusts his team and his instincts. Ideas, problems and feedback are directly incorporated into the further development of his machines. If a device does not function reliably in everyday use or is cumbersome to operate, it will be improved. Immediately. Often, only a few days pass between the idea and its implementation.

A classic research and development department? No such thing here. Bloos focuses on pragmatism rather than process, on craftsmanship rather than high-gloss strategy. He encourages the staff to be creative. "Don't talk, do!" has long since become the unofficial company motto over the years. It's Heizomat's "Carpe diem". Many team members work with the products themselves, whether in service, assembly or at home. Their feedback comes directly from everyday production. This close connection to the product is deeply rooted in the company's DNA. Robert Bloos senior, the company founder, was an entrepreneur with principles, believing it was better to be solid than speculative, down-to-earth rather than aloof. His son continues this approach consistently – with an open, practical culture of innovation.

Whether in the yard, in the excavator or in the office – for Robert Bloos, the future begins with responsibility. And with the courage to simply begin. But even a pragmatist has to think strategically. Japan and the USA are on his agenda. Aside from their high affinity for technology, these markets also offer the opportunity to reduce dependence on the European market. Heizomat thinks internationally – even if its roots remain in the region. And at some point, his son could take over. The eleven-year-old already enjoys watching his father at work and helps out in the company. But Bloos doesn't provide him with any direction. "He needs to forge his own path." Just like he once did himself.