Solutions

EKPO was seeking a laser welding solution that was precise, and fast, while retaining process reliability. "It was clear to us that we needed a laser that would work extremely precisely, but also do so reliably under industrial conditions – and TruFiber can do that," says Bayer. EKPO was particularly impressed by the combination of excellent beam quality and high process reliability. "Bipolar plates require a great deal of expertise. At the same time, they are also genuine mass-produced products, as we need up to 400 of them per fuel cell. And each plate has up to three metres of weld seams". EKPO manufactures around 10,000 stacks per year. So the fibre laser at the Dettingen site has to produce some 12,000 kilometres of weld seams annually – equivalent to a round trip between Hamburg and New York .

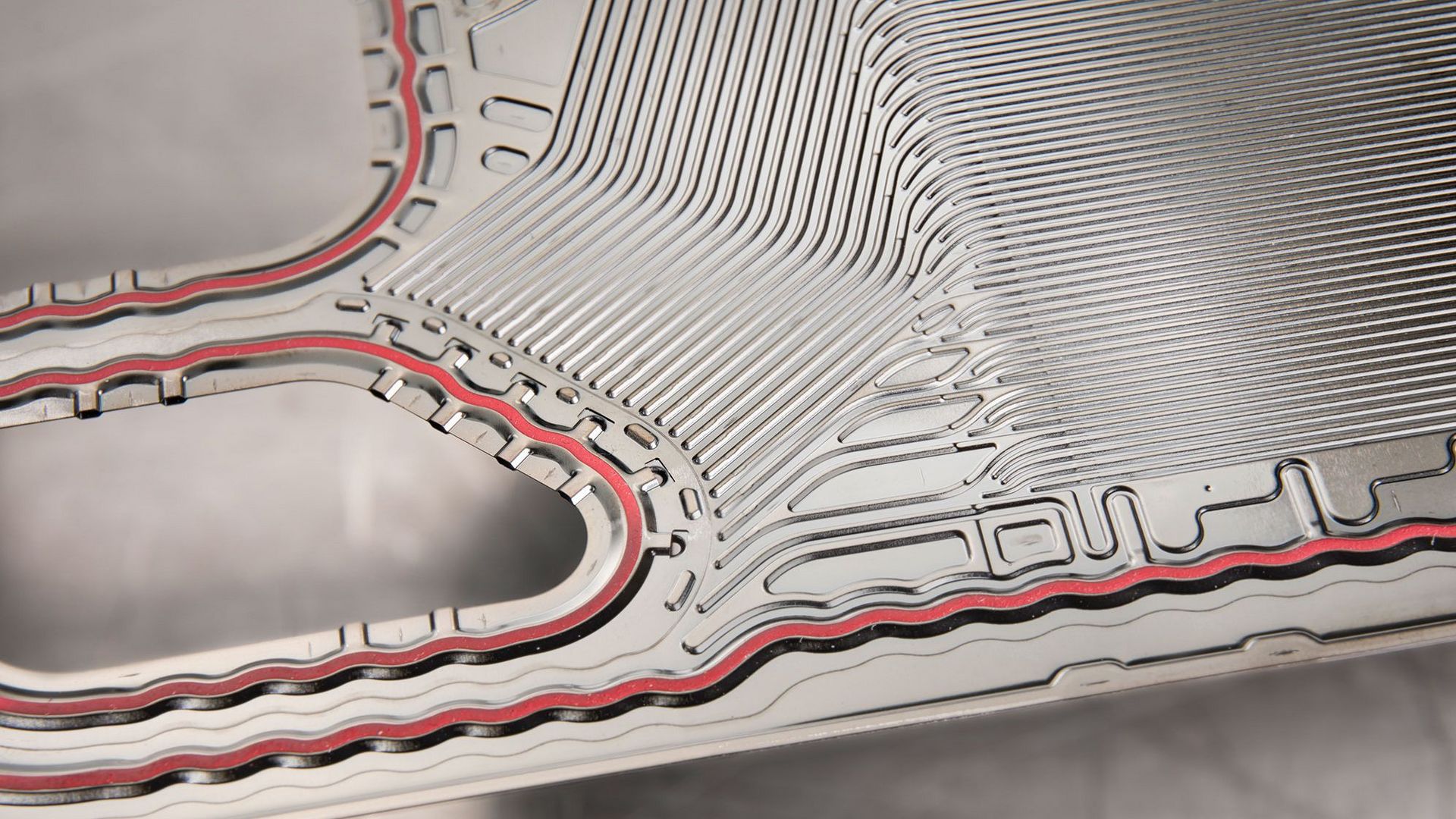

Implementation

In EKPO's automated production line, the laser beam connects the two sides of the bipolar plate to form a gas-tight unit – using weld seams with a maximum width of 0.2 millimetres. In this process, EKPO operates close to the "humping" speed limit, at which physical factors cause unwanted bead-like protrusions in the seam. The fibre laser handles this effortlessly, and consistently delivers high-quality results, with a reject rate of well below one percent. The welding process is followed by a rigorous conductivity and leak test at up to two bar pressure. If the weld seams hold up, the bipolar plate is ready for the stack.