Challenges

Automotive supplier GEDIA produces body parts of various sizes. This range requires a high level of production flexibility. Cost-effective automation is often difficult to achieve. When GEDIA secured an order to manufacture a large number of longitudinal beams, conditions finally aligned in favour of automation. "After initial planning, it was clear that we could use at least two lasers at 100% capacity for this one item. The containers required for automation were supplied by the customer. "Perfect conditions," says Pascal Kaufmann, Head of Production at GEDIA. In addition to the number of parts, the weight and dimensions of the longitudinal beam also required automated processing. Weighing around 8 kilograms and measuring about 1.80 metres in length, they were too difficult for employees to handle.

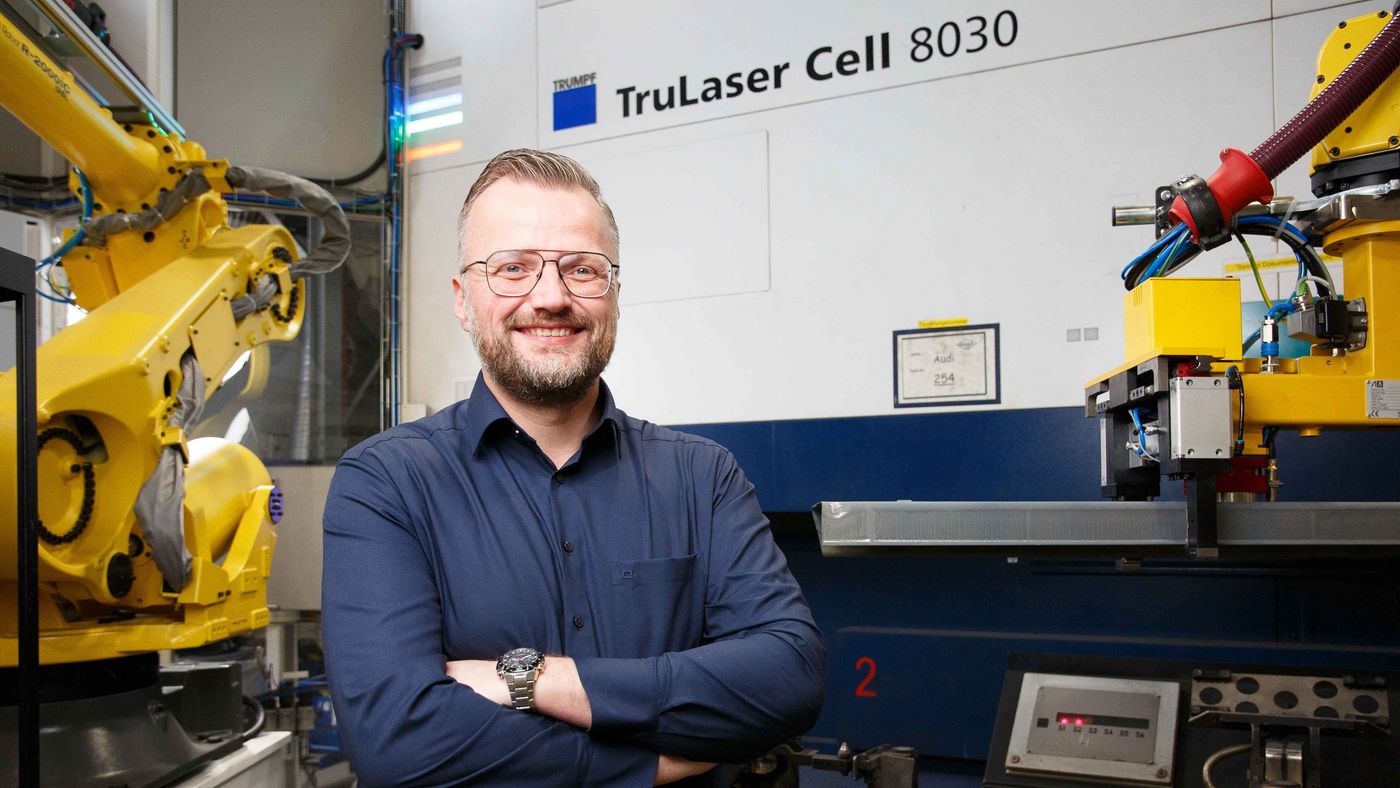

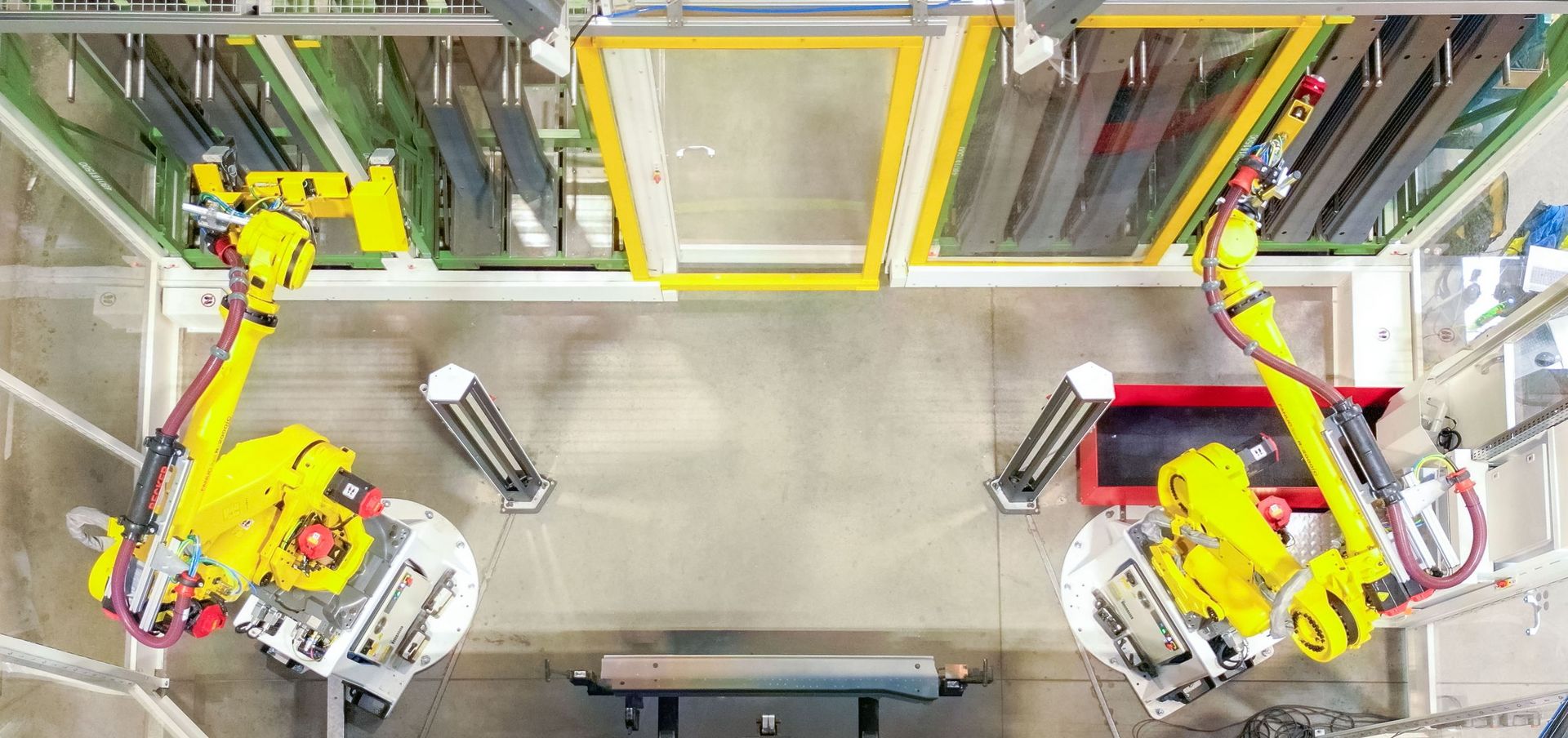

Kaufmann and his colleague Björn Müller, Project Manager for Capital Goods in Machine and Building Management at GEDIA GmbH, called on TRUMPF for assistance. In a joint workshop with TRUMPF experts and specialists from solutions partner Autom8, they explained exactly what they would need from a fully automated process. "Container management was a crucial area," says Müller, explaining: "We need specialist containers for an automated process. Purchasing them is expensive, and the associated handling and storage further reduce cost-effectiveness". Quality assurance through suitable camera systems and sophisticated gripper technology were also on the agenda. "Parts produced from hot forming usually have a funnel shape and a rough surface. They are stacked for further processing on the laser. Automated gripping and, above all, separating the parts is quite a challenge", says Müller. Last but not least, there was only limited space available for automation.

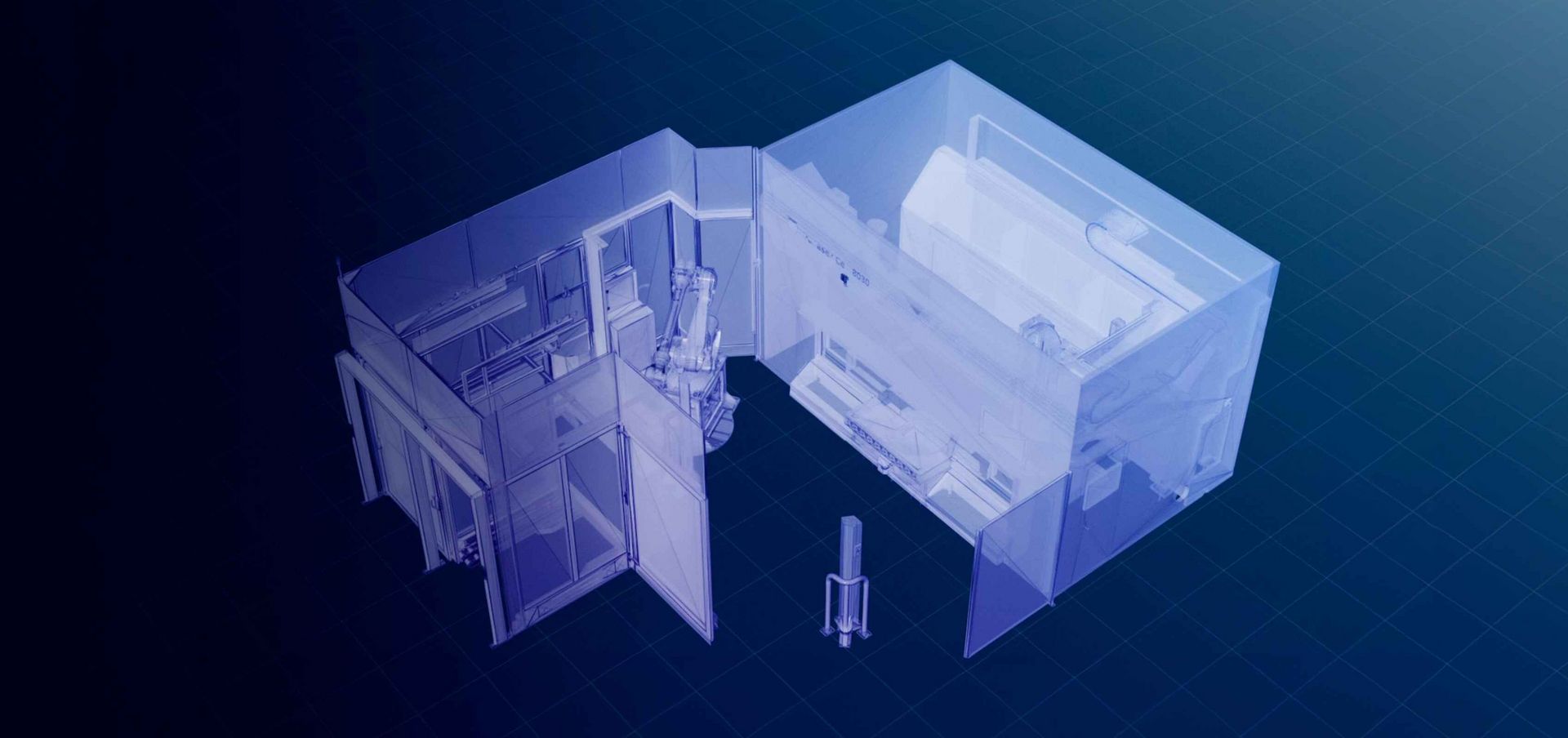

TRUMPF and Autom8 come up with a compelling solution, whereby two existing TruLaser Cell 8030 machines are fitted with an innovative single-robot automation. Its compact design allows for both automated and manual operation of the TruLaser Cell 8030, making it ideally suited to the available space in GEDIA's production facility. But shortly afterwards, flexibility was required again as changes in quantities required the automation of another TruLaser Cell 8030. However, since this system can only be used to half its capacity for the production of the longitudinal bar, it was difficult to know what to do for the best. Based on their positive experiences with the first two automation projects, Kaufmann and Müller are now taking the next step and commissioning a fully automated system that will allow the longitudinal beam and another similarly sized part to be produced around the clock, with minimal setup time and little operator intervention.