Work ergonomically – with the TruBend Series 7000, a high value is placed on ergonomics. It was the first bending machine to have an ergonomics certificate.

Ergonomic high-speed machine

The TruBend Series 7000 is a prime example of man and machine working in perfect harmony. The ergonomic high-speed machine bends small and medium-sized parts under the best working conditions, saving space for every production system. In addition to the high level of ergonomics and user-friendliness, due to the direct drive and our automatic angle measuring system, you achieve a high output at a very high level of quality. Operation sitting down or standing up is comfortable for the operator, and due to BendGuard Automatic, the setup operation is also extremely fast and safe.

With our high-speed machines, you can bend small and medium-sized parts ergonomically and highly productively whilst saving space.

Work both safely and quickly as the BendGuard Automatic moves independently to the height of the set-up tools due to the CNC control system.

With its small installation area, the compact TruBend Series 7000 will fit in any production system, and can even be transported by forklift truck.

The operator can work ergonomically with a standing and sitting aid. They can also adjust the support table individually.

You can rely on the bending angles being right from the first part.

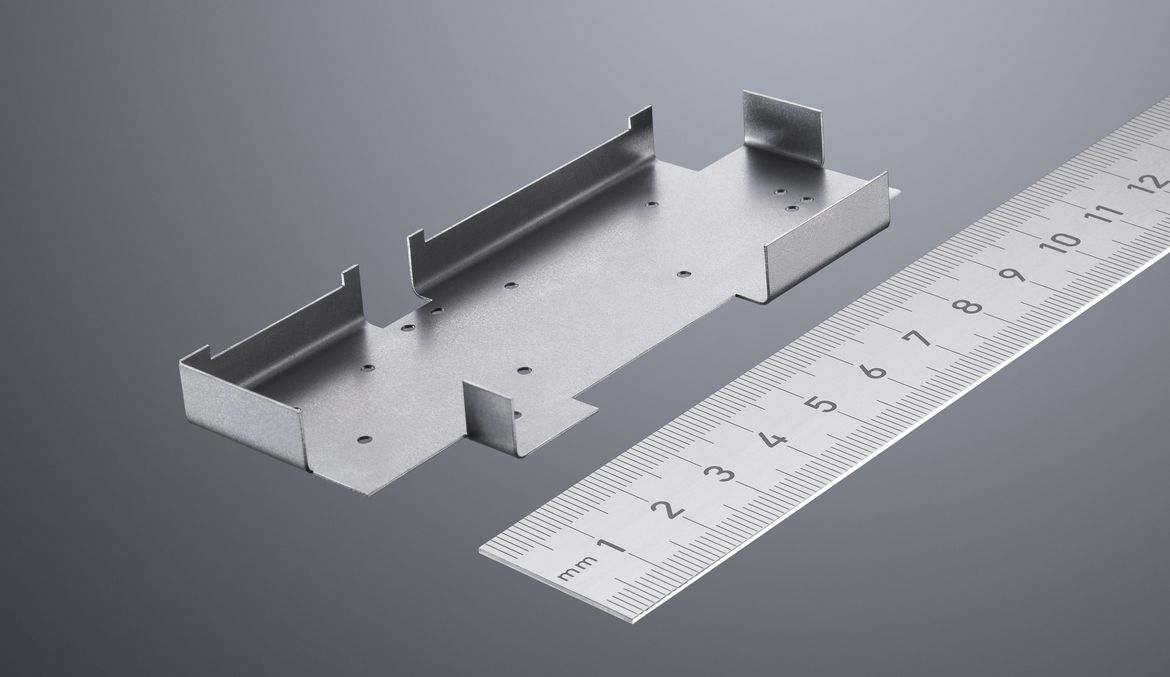

The TruBend Series 7000 bends parts up to 1500 mm in length with the expected quality. The TruBend 7050 has a higher press force, meaning it can bend thicker sheet metal parts.

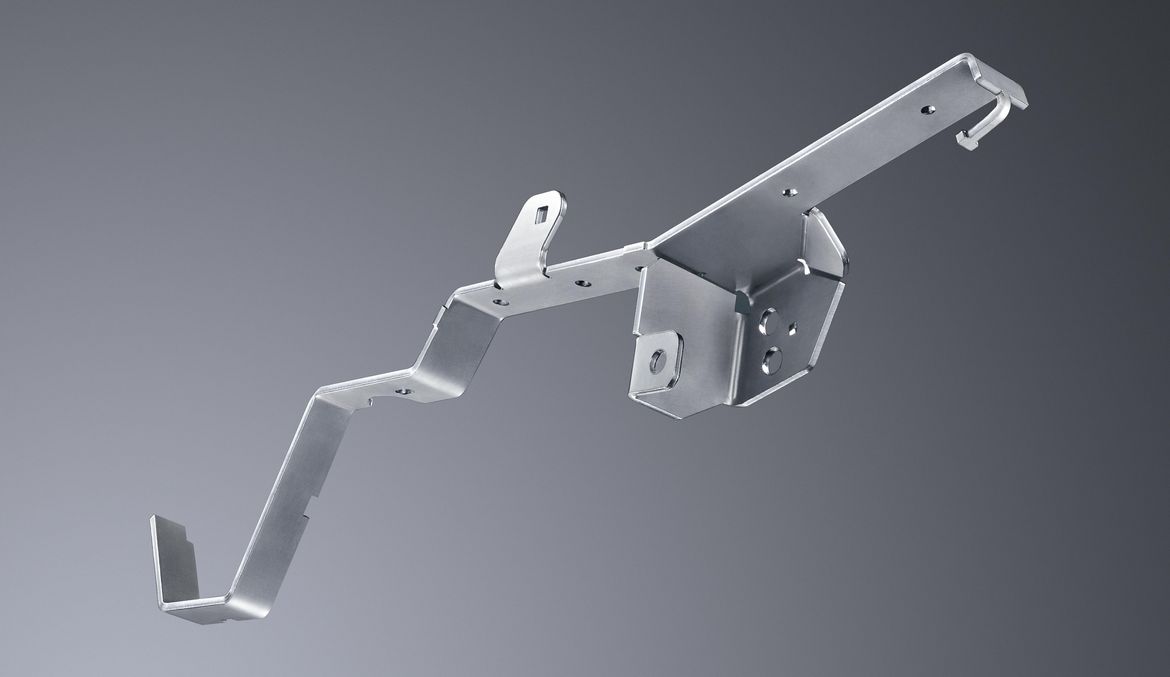

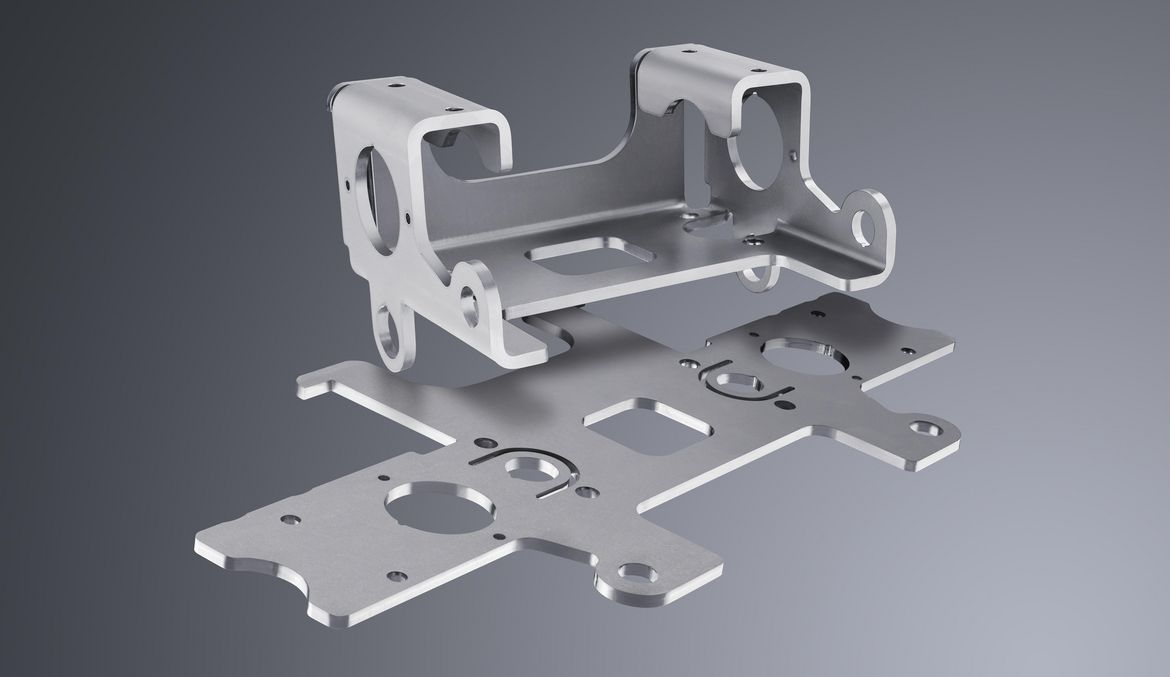

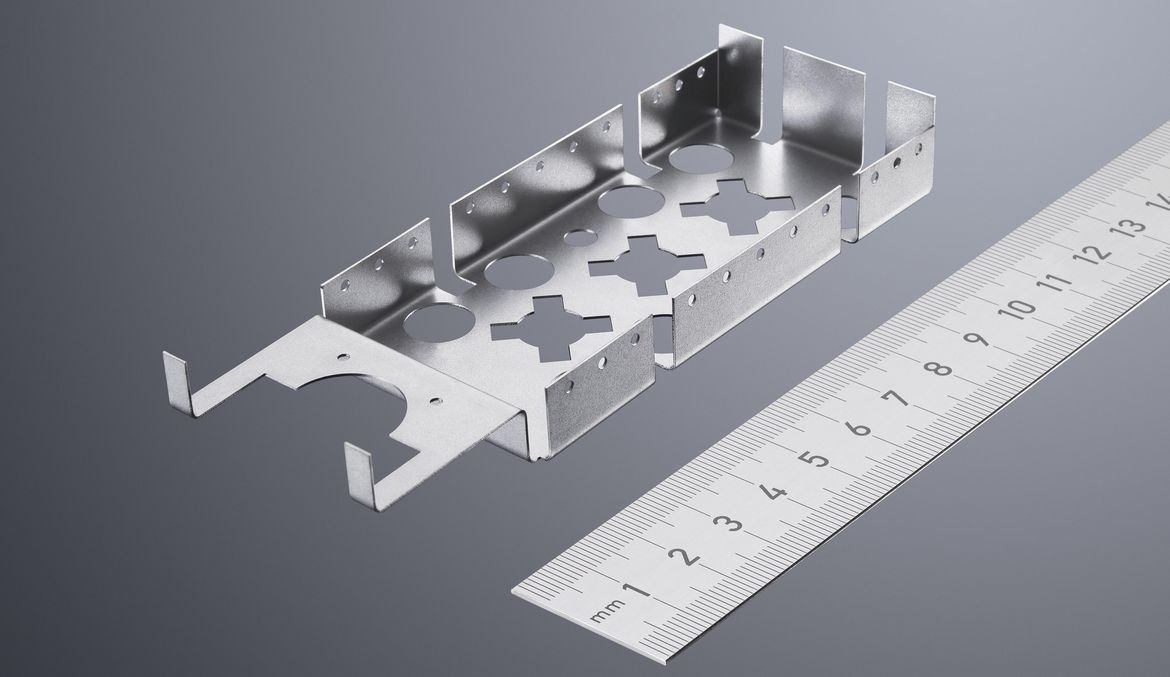

The TruBend Series 7000 also bends the smallest parts.

Small, precise bends are no problem for the TruBend Series 7000

You can also produce bends with short flanges on the TruBend Series 7000.

With the TruBend Series 7000, you can process small components highly productively and quickly.

|

TruBend 7036

|

TruBend 7050

|

|

|---|---|---|

| Press force | 360 kN | 500 kN |

| Bending length | 1020 mm | 1530 mm |

| Width between columns | 932 mm | 1305 mm |

| Usable open height | 295 mm | 385 mm |

| Throat depth | 150 mm | 250 mm |

| User interface | Touchpoint TruBend | Touchpoint TruBend |

| Dimensions, weights | ||

| Length | 1900 mm | 2420 mm |

| Width | 1340 mm | 1805 mm |

| Height | 2380 mm | 2580 mm |

The technical data of all product versions as a download.

Numerous functions make working with the TruBend Series 7000 even safer, easier, more ergonomic, and more productive.

Ergonomics

If the bending machine operator is doing well, the bending process goes well. The TruBend Series 7000 was the first bending machine to have an ergonomics certificate. The operator can work comfortably with a standing and sitting aid. They can also adjust the support table individually. The sitting and standing aid, as well as the swiveling control, are gentle on the spine. LED lighting guarantees the best visibility in the work area.

With the ergonomic support consoles, you always have access to tools, blanks, or personal items.

LED technology illuminates the process area without emitting heat towards the operator.

The control can be adjusted to the optimal inclination for working when standing or sitting. Reflections and mirroring can therefore be avoided.

Whether standing or sitting, the operator always has an ergonomically balanced work environment.

Even more comfortable: Depending on the lower tool height and the part geometry, the operator can adjust the arm rests to their seated position.

The document holders serve as storage for drawings and production documents.

Precision combined with productivity

The 6-axis backgauge guarantees the exact positioning of your components.

The user-friendly ACB Wireless system measures and corrects angles using two sensor disks which are integrated in the upper tool. During bending, these sensor disks touch the inside of your bending part. In the process, together with sensors, they measure the exact angle electronically and ensure that it is perfect. The control and angle measuring system communicate wirelessly here.

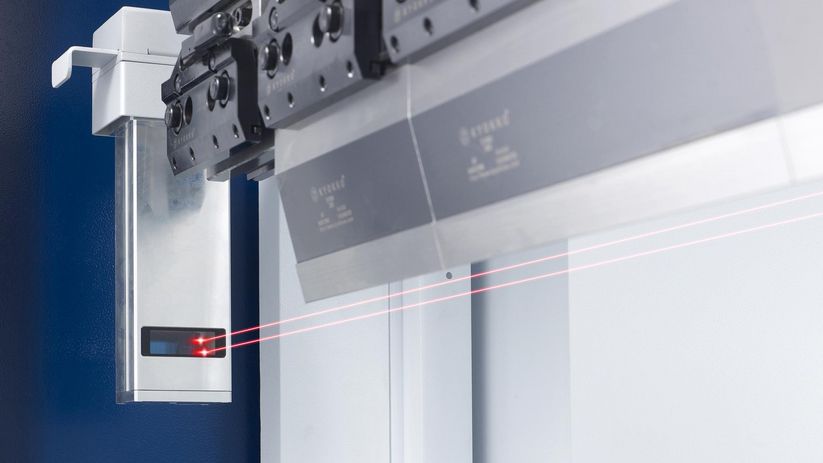

The BendGuard safety device monitors the area beneath the upper tool through a light field. Manual setting of the safety device is also a thing of the past due to BendGuard Automatic. With the help of the CNC control, BendGuard automatically moves to the height of the set-up tools. You are saved the otherwise common hand movements as well as valuable setup time, and can work safely and error free.

TruBend Touchpoint is the simple interface for operating your bending machine. Navigation follows an intuitive logic. The views are reduced to the essential items, and realistic 3D visualizations with collision check simplify processing. This means every application has the perfect solution – from simple to complex components. The integrated help also simplifies operation at the machine – it can be called up using two fingers and simple gestures such as swiping.

Small and compact – with its small installation area, the TruBend Series 7000 will fit in any production system, and can be transported by forklift truck. When bending small and minute parts, the machine is a great help. Due to the geometry of the gauge finger, you can also position parts with very short flanges easily, and collision-free.

The right program automatically – you can use the 2D code scanner to call up the right bending program in an instant. The scanner, which is connected to the machine, reads a bar code or Data Matrix Code from the paper, and automatically loads the program. This saves you time spent searching or entering data.

The tools are clamped at the press of a button.

Seamless integration of multiple TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

TruTops Boost

Program your bending machines intelligently using TruTops Boost, the all-in-one solution for 3D design. Numerous automated processes save you time-consuming routine processes. You also profit from a comprehensive ruleset with the bundled technical expertise of TRUMPF.

TecZone Bend

TecZone Bend is the fastest and most simple programming for bending machines, and provides great support for every user. You can therefore either program at the machine or offline in the office, and can change back and forth seamlessly between both worlds. On the basis of 2D and 3D data, the TRUMPF software automatically creates program suggestions including NC programs. Within seconds, it calculates your bending programs – including real-time collision check, dismantling of assemblies, management of setup plans, and much more. The prioritization of tools reduces the work required and increases the productive time that your machine is in use.

Software

The software portfolio from TRUMPF optimizes your entire production process – from the customer query through to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customized Industry 4.0 solutions for your Smart Factory.

You can choose between more than 150 upper and lower tool types for your personal range. You can order tools individually or as a set.

For tools up to 12 in. long, lightweight tools with a weight saving of more than 30% are equipped with the Safety-Click as standard. This reduces the setup time and relieves the strain on the operator.

During the processing of galvanized sheets, even after just a few bends, there may be zinc deposits on the die, resulting in cold welding. This causes imprints on the component and imprecision. This can be avoided with the coated LASERdur ZN TRUMPF bending tools. They combine a high level of surface hardness with excellent sliding properties, are corrosion resistant, and do not need to be cleaned.

For specific requirements, TRUMPF will develop your own personal tool solution. To guarantee the quality of your parts, we test the tools in advance with your specific material and create initial sample parts.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.