Condition Monitoring: catch faults before they happen

A mid-sized, family-run shop turns out hundreds of control cabinets every day, with virtually no buffer in the schedule. The laser cutting machine seems to be running like clockwork, but repeated acceleration is quietly loosening the cutting-head mounting. The problem is invisible to the operator, but it could result in quality issues or damage to the machine. Fortunately, the Predictive Service Center spots the anomaly early on via Condition Monitoring; after running detailed diagnostics, it gives the user specific instructions to tighten the mounting. Thus, one simple step prevents unplanned downtime. In this scenario, the customer benefits from a maintenance contract with TRUMPF thatxincludes Condition Monitoring. This option is also available as part of other service agreements – making scheduled maintenance easier, reducing stress and keeping availability consistently high.

Service app: confidence in the next step

In the past, a fault code on a machine display inevitably led to unplanned downtime. Today, a maintenance technician at an automotive supplier opens a digital service ticket in the TRUMPF Service App, selects the machine and fault – and receives instant support. Is the problem excessive mechanical resistance, or an electrical-signal issue in the bending machine? Depending on the fault, the operator receives step-by-step illustrated instructions for on-site troubleshooting through the Technical Guide; for example:

1. Check ACB Laser for stiffness and lubricate. 2. Remove the housing cover and test the proximity switch. 3. Tighten the drive coupling and check belt tension. Moments later, the machine is back in operation.

If the technician still has any doubts, they can connect directly to TRUMPF Remote Support via the app. A specialist will then provide live assistance with Visual Assistance, with no wait time and no need for a site visit. Some 70 percent of issues can already be solved remotely without requiring a site visit. With ever more connectivity and diagnostic tools available, remote support is faster, more direct and more convenient than ever. The Remote Service Contract makes this rapid support possible, with hotline access, remote login and real-time assistance. For those who want more long-term security – including spare parts, on-site visits and scheduled maintenance – the Performance Contract is the right choice.

Performance Check: reveal hidden potential on the shop floor

In Production at a metalworking company is stable, but output has fallen below expectations and quality is inconsistent. Keen to find answers, the production manager takes advantage of TRUMPF’s free Performance Check, first unveiled at INTECH and Blechexpo. A team of TRUMPF experts analyses the machine data in advance, including machine-status records, service and error logs, and software versions – all enabled by the machines’ connection to the TRUMPF network via existing connectivity functions. In a brief consultation – sometimes as short as 30 minutes – the experts identify untapped potential, from digital features that the customer has forgotten or overlooked to practical tips on preventing unplanned downtime. Whether it’s a neglected filter, incorrect machine handling or a useful tool, small changes can have a big impact. For the customer, it’s a targeted way to make sustainable improvements to efficiency. All made possible thanks to smart connectivity from TRUMPF.

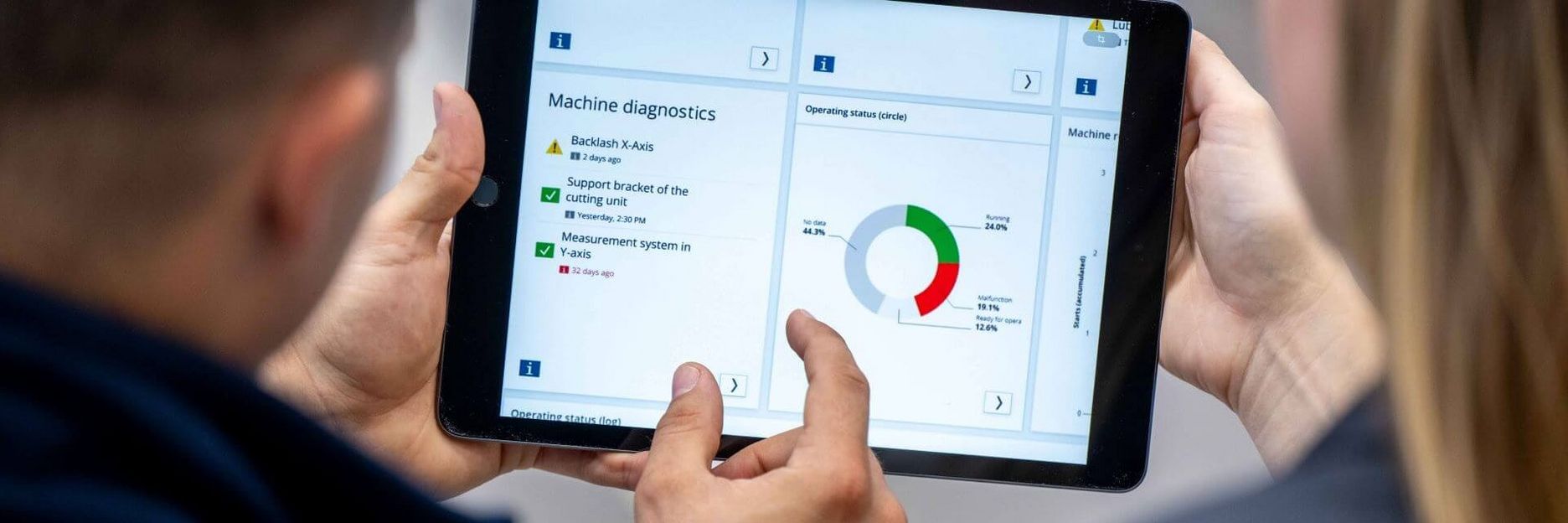

Smart View for Machine Tools: everything visible at a glance

It’s the morning walk-through at an agricultural machinery plant, and the production manager wants to know if there are any anomalies and if the laser cutting machine is running as planned. A glance at the Smart View for Machine Tools dashboard provides all the answers. Machine status, operating hours, downtime, program analytics and Condition Monitoring data – everything is presented in one convenient overview. Even downstream processes

such as bending are visible through Oseon connectivity. As well as saving time, this overview offers the clarity needed to make decisions. With this simple, efficient and digital solution, operators can instantly spot deviations, analyze performance in just a few clicks and make targeted improvements to workflows.

Service fit for the future: spot more, pay less

TRUMPF is continually improving its service offerings and contract models to make things even easier for its customers over the long term. By servicing their machines regularly and using digital tools, customers gain the double benefit of fewer failures and better conditions. At the same time, TRUMPF is constantly expanding its digital solutions. In the future, this will make it even simpler for customers to spot problems early on and fix them remotely – with no on-site visit required. Service that thinks ahead – and pays dividends.