Melt travel at a glance

The TRUMPF melt travel monitor monitors the lowering of the component during the laser transmission welding of plastics. The laser is switched off after a certain melting of the material. This provides you with better process monitoring and enables you to balance out production tolerances. A commercially available inductive melt travel sensor is also connected directly to the head of the scanner optics via an analog interface. The melt travel is displayed using the same software that is also used for the temperature control. You can also set up quality data storage (QDS). The melt travel measurement series then give you information regarding the quality of the welding process.

Process control using the melt travel to switch off the laser after a certain amount of material melting.

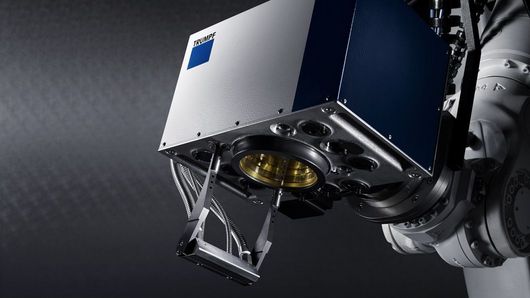

The interface for the melt travel sensor is located directly on the scanner optics of the PFO series.

The melt travel can be saved as a measure of quality for the process and can be evaluated.

Welding plastic components

The melt travel monitor ensures safe processes in axial welding with scanner optics on plastic housings of electronic control units, sensors, and actuators.

Compatibility of sensor systems

| PFO 2D | PFO 3D | BEO D35 | BEO D70 | |

|---|---|---|---|---|

| TruFlow | ||||

| TruDisk | ||||

| TruPulse | ||||

| TruFiber | ||||

| TruDiode | ||||

| TruMicro |

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.