Sustainability is now important in staying competitive in sheet metal processing. "When a company can demonstrate that it has succeeded in improving its eco-balance, customers often prefer to buy its machines," says Tim Veith, Sustainability Manager at TRUMPF. An important factor here is the careful handling of machines and materials. This is because one ton of steel consumes around 1.4 metric tons of CO2, depending on the manufacturing process. It is not uncommon for machines used in sheet metal processing to weigh in at over 10 tons. For a company to reduce its carbon footprint, it is therefore worthwhile to fully utilize machines for as long as possible. However, using old equipment is often at odds with emerging trends such as digitalization or artificial intelligence. Such trends require companies to collect and analyze masses of data. If a machine is not capable of doing this, companies often discard it. TRUMPF is the leading supplier for and user of digitally networked production. This expertise has enabled the company to develop various technologies which customers can use to retrofit their old machines and thus make them viable for future use.

Retrofit instead of disposal

The OPC UA Retrofit Cube is a TRUMPF solution that upgrades old machines to the latest standards. It is used to add an OPC UA interface to older machines. This is an international, platform-independent standard for data exchange between manufacturing machines. Machines using the OPC UA interface can then be connected to software systems. One of the standard's features is enabling digitally networked production. Newer machines from TRUMPF are equipped with this interface. Older models can be upgraded for future viability by using the OPC UA Retrofit Cube. TRUMPF customers need to connect the cube-shaped electrical cabinet to their machine. Installation is quick and easy, and the technology is inexpensive. "The OPC UA Retrofit Cube gives customers a solution that enables them to use state-of-the-art communication technologies with their old machines. This increases competitiveness and saves resources," says Tobias Grass, Product Manager for Networking at TRUMPF Machine Tools.

Predictive maintenance for a longer service life

Predictive maintenance in machines is also a way of protecting the environment in sheet metal processing, because unplanned machine breakdowns in series production drives up the manufacturing carbon footprint. When machines suffer a drop in performance and this is not noticed in time, components already manufactured are often unusable and the company has wasted material. Predictive maintenance means machines send data about their condition digitally and in real time to a database. Irregularities are then automatically detected and the components responsible are identified. However, older machines are not always capable of transferring the relevant data to the database. TRUMPF therefore developed the "Smart Power Tube IoT Box" for CO2 laser machines. This simple and inexpensive solution can also be used in older machine versions. Just a few easy steps are required for customers to install the box on the machine's laser generator. The solution then transmits data to TRUMPF with information about the machine's condition. If the monitored machine stops delivering the required performance, TRUMPF experts inform the customer, dispatch a genuine part, and arrange an appointment to carry out replacement work. This conserves resources and increases productivity.

Recycle instead of disposal

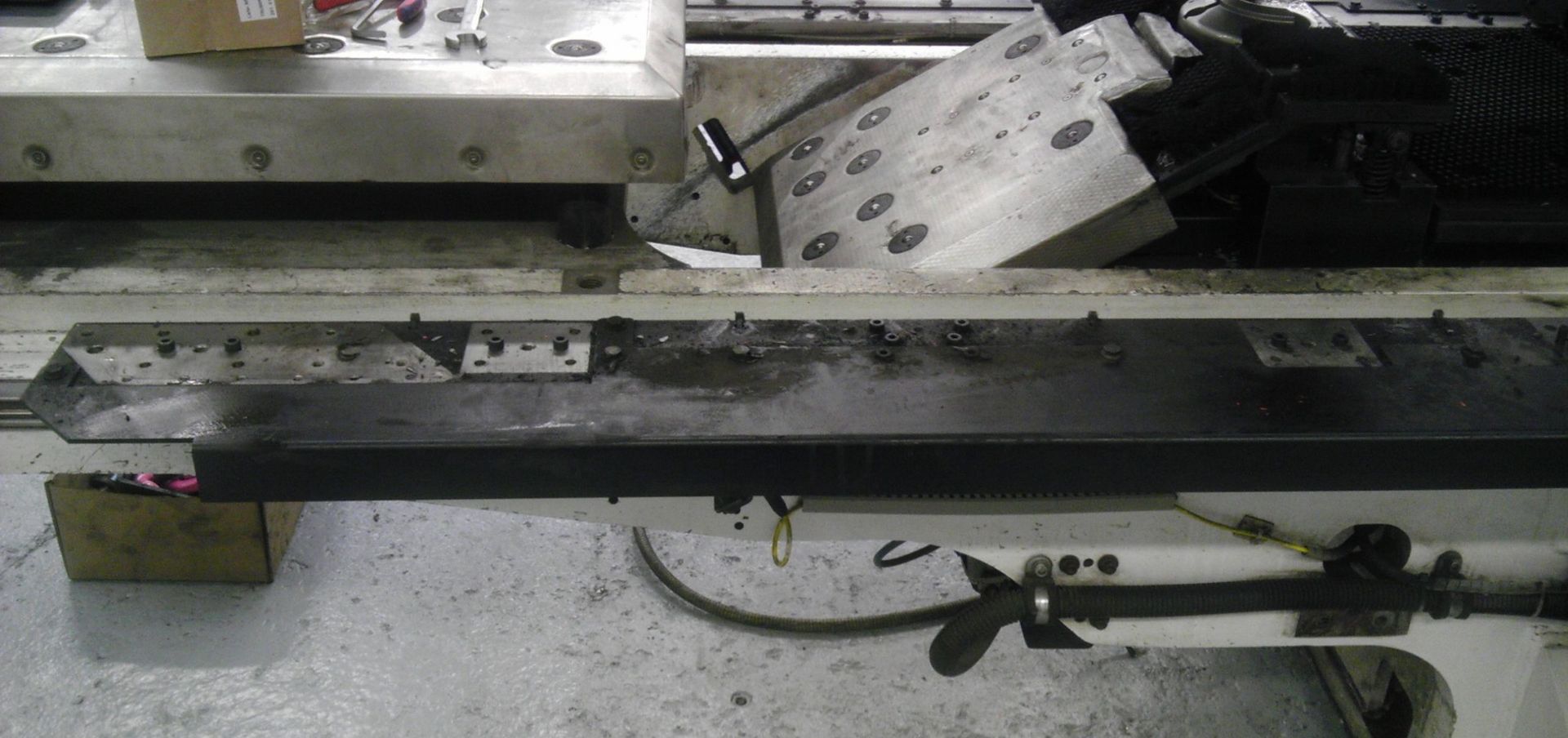

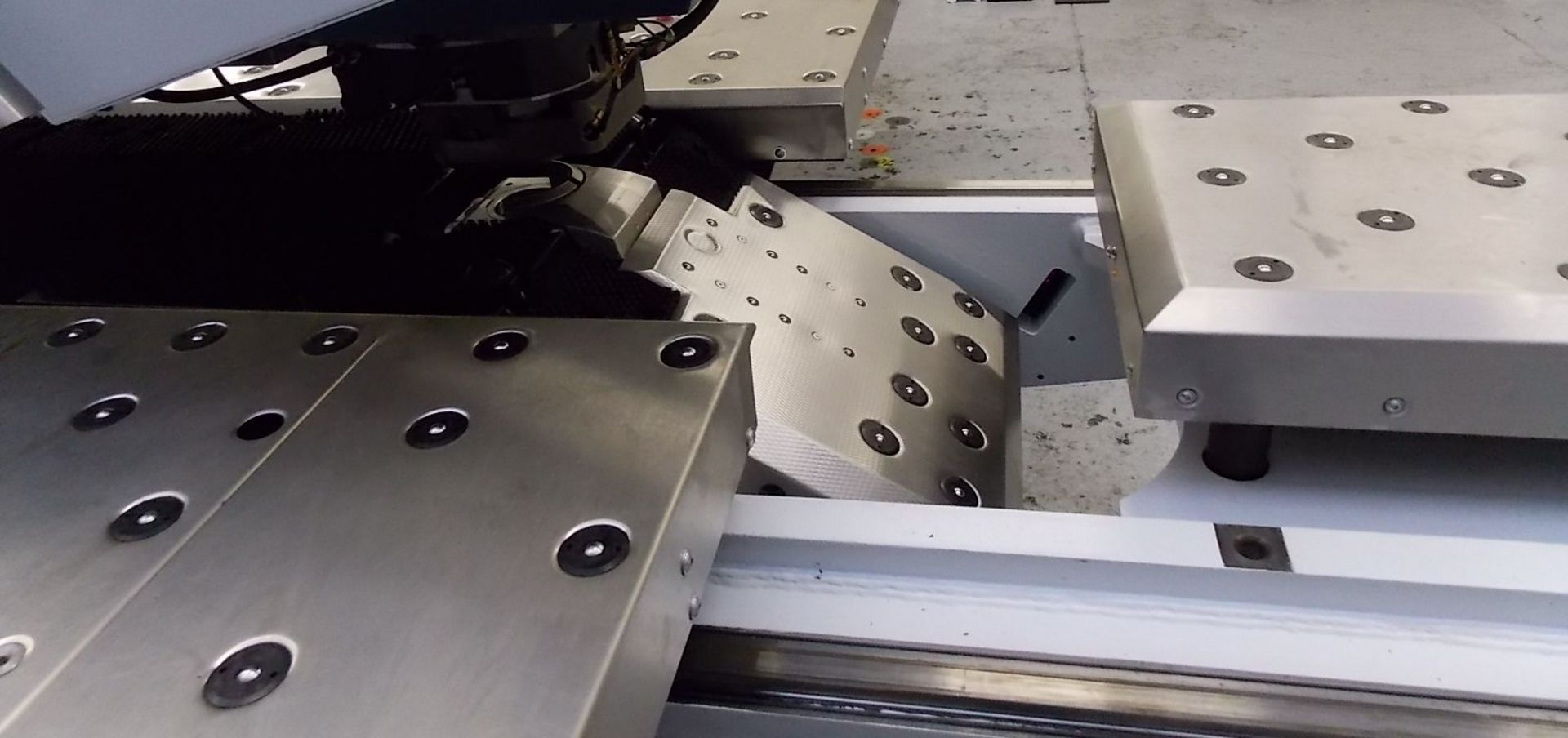

When a TRUMPF machine does become obsolete despite all efforts, users do not have to scrap it. Instead, they can sell the machine to the "TRUMPF Resale Center". The team there will refit the machines and put it back onto the market. In a dedicated TRUMPF plant in Holland, employees dismantle the machine, clean it and replace worn parts. The refurbished TRUMPF machines are now fit for a second life cycle. A survey was conducted by the TRUMPF Resale Center last year which showed that refurbished machines will continue to run reliably for at least ten years with their second owners. When a company in the sheet metal processing sector opts for a pre-owned machine instead of a new one, it often saves not only on money but also on CO2. This is due to the savings that will be made on the energy that would have been required to manufacture the raw steel for a new machine body. To get an idea of things, a machine like TRUMPF's TruLaser 3030 weighs about 12 tons. Recycling the machine body alone saves the company around 16 tons of CO2. Since downstream processes in machine manufacture are also eliminated, users will consume around 20 tons less CO2.