A roll of coiled aluminum hovers two meters above the ground throughout the production facility. Martin Müller, machine operator at the fischer group, purposefully guides the coil with the machine crane to a 34 meter long system – the TruLaser 8000 Coil Edition from TRUMPF. Müller precisely sets the coil in the loading zone and starts removing the protective plastic film from the aluminum by hand. The system takes care of the rest. A laser beam dances across the sheet and quickly and precisely cuts out the components. At the same time, a robotic arm quickly removes them from the scrap skeleton and neatly sorts them into several stacks in the system's unloading area. "Laser blanking is a cool technique," says the trained locksmith, throwing the film into a waste container.

With laser blanking, the laser cuts the components directly from the coil instead of from a metal sheet. This means that large quantities can be produced particularly efficiently. Users also save material because they can nest the components on the coil more efficiently.

Laser blanking: perfect for large quantities

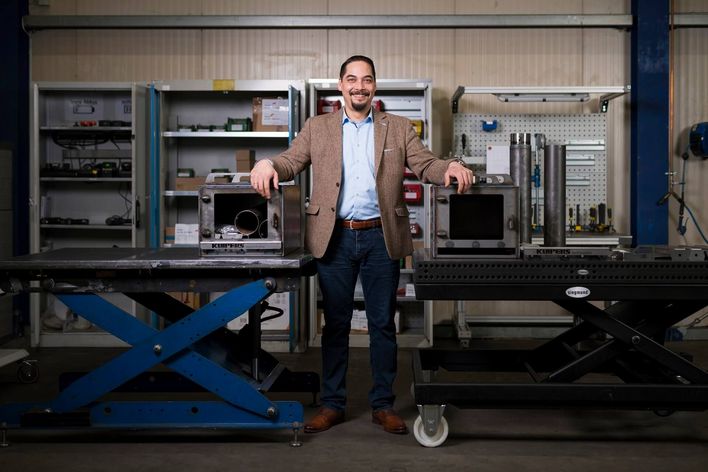

The fischer group supplies components to important future industries, such as electromobility or the semiconductor industry. The family-owned company started out in tube processing. Today, the company employees over 2700 people and is a renowned supplier for OEMs across the world. "We needed a solution that would allow us to produce large quantities of different geometries for our customers quickly and with high precision without having to convert the system," says Hans-Peter Fischer, CEO and owner of the fischer group. Fischer speaks calmly with a slight Baden accent. He rarely wears suits, instead his employees often see him in the production halls.

Business with the automotive industry is one of the reasons why Fischer brought in the new laser blanking system from TRUMPF. The company uses what is known as aluminum hot-forming technology to manufacture lightweight, high-strength structural components that are particularly suitable for electric cars. This also applies to the outer door ring for the flagship model of a well-known American premium electric car manufacturer. The bodywork part is integrated into the A and B pillars, including rocker panels, and weighs just under nine kilograms. Fischer is proud of the future-oriented component that his company produces. That's why it has set up its modern reception area as an exhibit true to the motto "US mobility made in Achern".

More productivity thanks to laser blanking

Producing economically is also the top priority for the fischer group. While the project team was still working on the core process of the new forming process, the engineers at the fischer group were looking for alternatives so that they no longer would need to buy pre-cut sheet metal. "In 2021, we became aware via the press that TRUMPF was developing a laser blanking system. We knew straight away that we needed it", confirms Hans-Peter Fischer.

In the same year, a separate building for the new TRUMPF system for laser blanking was built on the factory premises. Hall 16 now houses the imposing 34 meters long and ten meters wide testimony to German mechanical engineering that TRUMPF developed at the Neukirch site. Loading cell, cutting cell, stacking area - everything is highly automated. There are always around 20 coils stored at the end of the hall which machine operators like Martin Müller hoist into the system's loading zone using the machine crane.

Investing in the future

The construction of the new hall and system cost the fischer group around eight million euros. A sum that is not paid off with the first order. But it doesn't need to be. Ultimately, the future viability of the company played a role in the decision - and fischer in Achern has now taken a big step in this direction. Hans-Peter Fischer knows that the German automobile manufacturers take their US competitors seriously and keep a close eye on what is going on in their state-of-the-art production plants. For the fischer group, the production of the B-pillars with the help of laser blanking for the American electric car manufacturer is an order with magnetism - follow-up jobs haven't been ruled out.

4000 tonnes less CO2 thanks to laser blanking

Laser blanking can do even more: With their solution, TRUMPF is supporting manufacturing companies in making the future trend of more sustainability in production a reality. Compared to conventional machines for laser cutting, companies can save almost 1,700 tonnes of steel per year with the TruLaser 8000 Coil Edition. That corresponds to around 4000 tonnes of CO2 and 1.6 million euros in material costs. Hans-Peter Fischer confirms after the customer test phase: "The strategic decision to work with aluminum coils and laser tools has made our production more flexible and economically competitive. With this system concept, we are in the optimal position.”