Hydrogen is considered the energy source of the future – light, clean and almost infinitely available. But this inconspicuous element has its drawbacks – it must be cooled to minus 253 degrees Celsius to remain in liquid form, and in gaseous form requires huge amounts of storage space. When used in vehicles or industrial plants, this promising technology quickly becomes a technical challenge. The start-up tech company NITIU wants to change this. It has developed an isotropic lightweight structure (ILS®) – a patented metal lattice made of countless tetrahedra that is simultaneously ultra-lightweight and exceptionally stable. Isotropic means that the structure reacts the same in all directions, i.e., it can absorb forces equally well from all sides. It is precisely this property that makes it the ideal basis for a new type of hydrogen tank that can withstand loads from all directions and store the energy source extremely efficiently. NITIU uses lasers to manufacture its innovative concept.

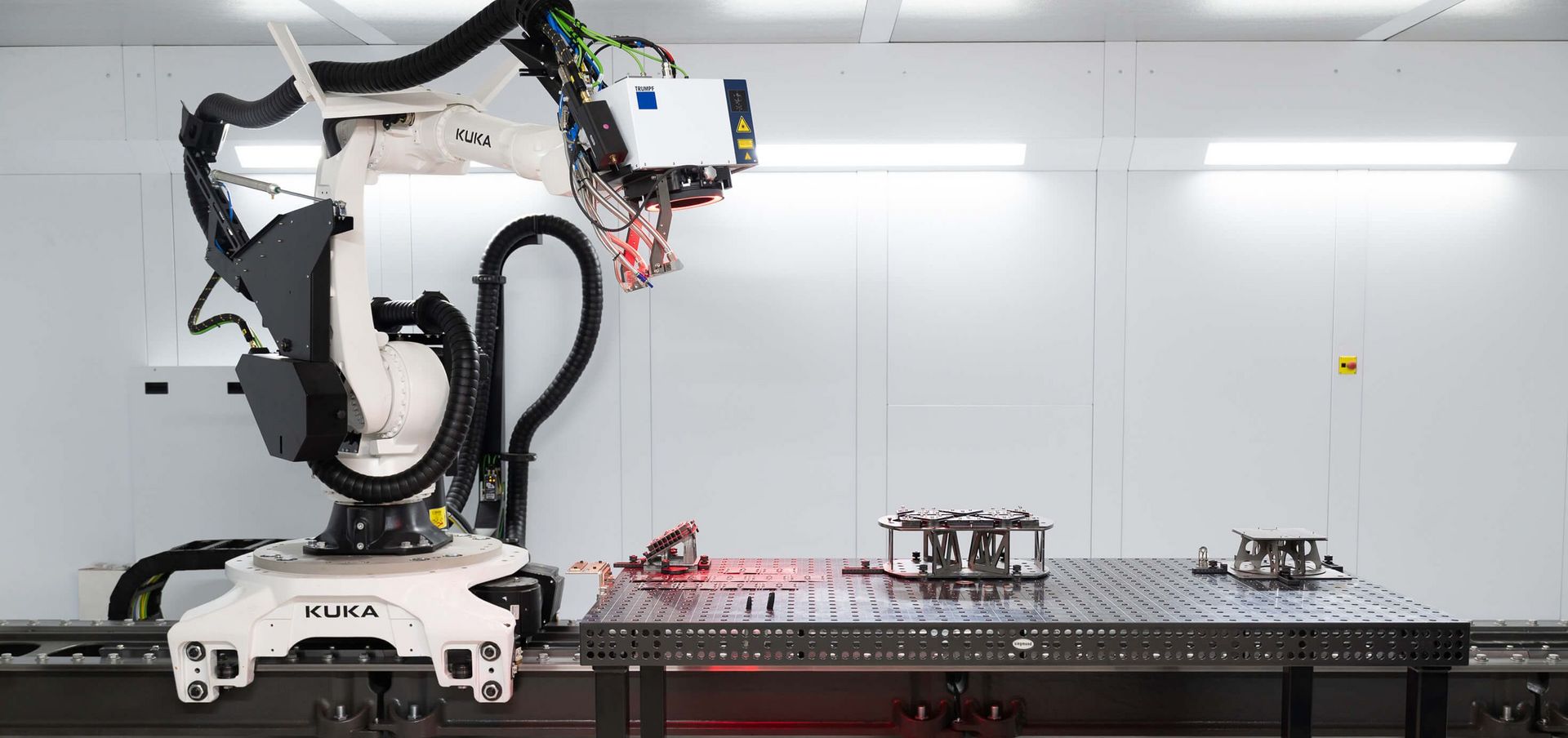

High-precision laboratory

"When I started at NITIU four years ago, laser processing didn't play much of a role," explains Joseph Hainsworth, the company's technical director. "But I quickly realised that lasers are the key to joining our structure precisely and exploiting its stability in full." In order to be able to use the tool in a targeted manner, Hainsworth and his team decided to develop their own laser laboratory, tailor-made for testing and further development of the ILS® structure. "Our goal was to work independently, increase quality and drastically shorten development cycles," explains Hainsworth. He spent a year travelling around Europe in search of suitable technologies.

High-tech combined with flexibility

He found what he was looking for at TRUMPF. "About six months before we ordered the machines, we began an in-depth dialogue with the laser experts at TRUMPF," recalls Hainsworth. "It was important to us that the systems were flexible and complemented each other – and TRUMPF understood that perfectly." The heart of the new laser laboratory is a TruLaser Cell 3000 and a TruLaser Weld 5000 with PFO 3D optics (programmable focusing optics) for precise welding in two and three dimensions. TRUMPF adapted this combination specifically for NITIU. The optics feature precisely controllable mirrors that enable the laser to move in 3D space. "It does this incredibly precisely – and amazingly quickly," says Hainsworth. "These optics are the most flexible component we have ever used."

Speed, quality, enthusiasm

Since the opening of the laser laboratory, work at NITIU has changed noticeably. "Previously, it took weeks before we could test changes to the concept. These days, we go to the lab in the morning, try something out and can implement it the next day," Hainsworth says happily. "The quality is higher, the processes are more stable – and we are constantly learning." TRUMPF tailored the systems precisely to NITIU's processes and combined all components to create a turnkey solution. "We could have commissioned other providers," Hainsworth explains. "However, TRUMPF's approach as a single-source provider was the decisive factor. This allowed us to focus on our own technology – on what we do best."

A step into the future

With its new laser center, NITIU has taken a giant step towards more efficient, lighter and safer hydrogen tanks. What began as a vision is now taking shape – lightweight, stable and laser-manufactured. "Sometimes I have to pinch myself", Hainsworth says and laughs. "It's just the coolest thing ever."

The Swedish company NITIU AB, based in Gävle, was founded in 2016 and specialises in the development and production of innovative metal lightweight structures. With its patented ILS® technology, NITIU contributes to the more efficient use of materials and energy – an important building block for sustainable mobility on land, at sea and in the air.