Ultrakurzpulslaser der TruMicro Serie 5000 bestechen durch extrem kurze Pulse von weniger als 10 ps und hohe Pulsenergien von bis zu 500 μJ. Sie verdampfen fast jedes Material so schnell, dass kein Wärmeeinfluss erkennbar ist. Die patentierte zweistufige Laserleistungsregelung mit integriertem externen Modulator macht den Laser absolut stabil, von Puls zu Puls sowie über den gesamten Leistungsbereich. Die Pulsspitzenleistungen liegen bei bis zu 40 MW.

Mikromaterialbearbeitung: maximal produktiv

Die Kurz- und Ultrakurzpulslaser von TRUMPF ermöglichen Ihnen Mikrobearbeitung mit einer optimalen Kombination aus Qualität, Produktivität und Rentabilität bei uneingeschränkter Industrietauglichkeit. Die besondere Puls- und Leistungsstabilität wird durch die Trennung von Pulserzeugung und Pulsausgabe erreicht. Die patentierte Steuerung sorgt für die Überwachung jedes einzelnen Pulses und hält Leistung und Pulsenergie exakt auf dem für die Applikation benötigten Niveau. Die Pikosekundenlaser der TruMicro Serie 5000 bestechen dabei durch extrem kurze Pulse und hohe Pulsenergien von bis zu 500 μJ. Und das bei exzellenter Strahlqualität und hohen mittleren Leistungen bis zu 150 W. Das sorgt für maximale Produktivität in der Mikromaterialbearbeitung. Sie verdampfen fast jedes Material so schnell, dass kein Wärmeeinfluss erkennbar ist. Daher sind sie optimal geeignet zum Bearbeiten von Halbleitermaterialien, Metallen, Dielektrika, Kunststoffen und Gläsern.

Der ultraschnelle Leistungsmodulator hält Leistung und Pulsenergie exakt auf Niveau.

Bearbeiten Sie temperaturempfindliche Werkstoffe ohne signifikanten Wärmeeintrag.

TruMicro Laser lassen sich leicht integrieren und sind kompatibel mit allen gängigen Schnittstellen.

100 % der mittleren Leistung auch in Einzelpulsen dank regenerativer Scheibentechnologie

Die auf der erfolgreichen Serie TruMicro 5000 basierenden Laser sind gemacht für Ihre täglichen Fertigungsaufgaben.

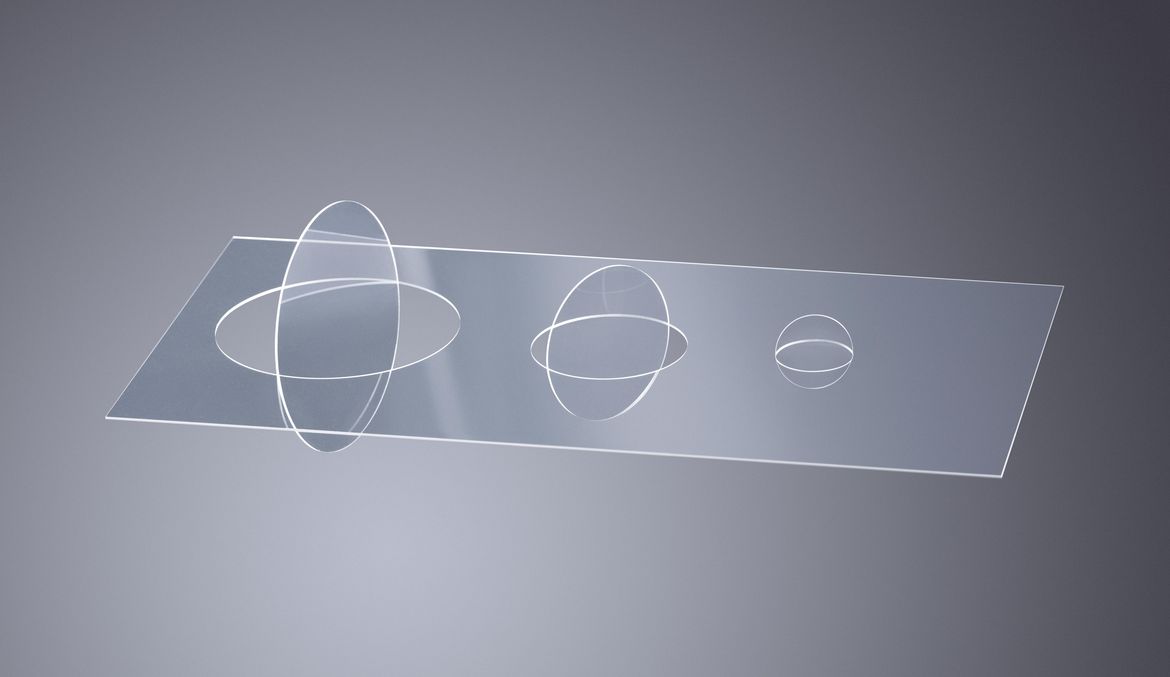

Laserschneiden von Glas

Die mechanische Belastung des Materials ist beim Laserschneiden von Glas mit einem TruMicro Ultrakurzpulslaser auf ein Minimum reduziert – es entstehen keine Risse an den Kanten, dadurch müssen die geschnittenen Bauteile nicht mehr abgeschliffen werden. Gerade in der Displayindustrie werden chemisch gehärtete Gläser als strapazierfähiges Schutzglas und Trägersubtrat eingesetzt und müssen geschnitten werden.

Hochgeschwindigkeitslaserschneiden von Glas

Der Laser ist derzeit das einzig schonende und flexible Verfahren, um chemisch gehärtete Gläser mit hoher Bruchfestigkeit zu schneiden. Die Gläser lassen sich mit dem Laser und der TOP Cleave Schneidoptik nach dem Härteprozess trennen, die Kantenqualität ist hervorragend.

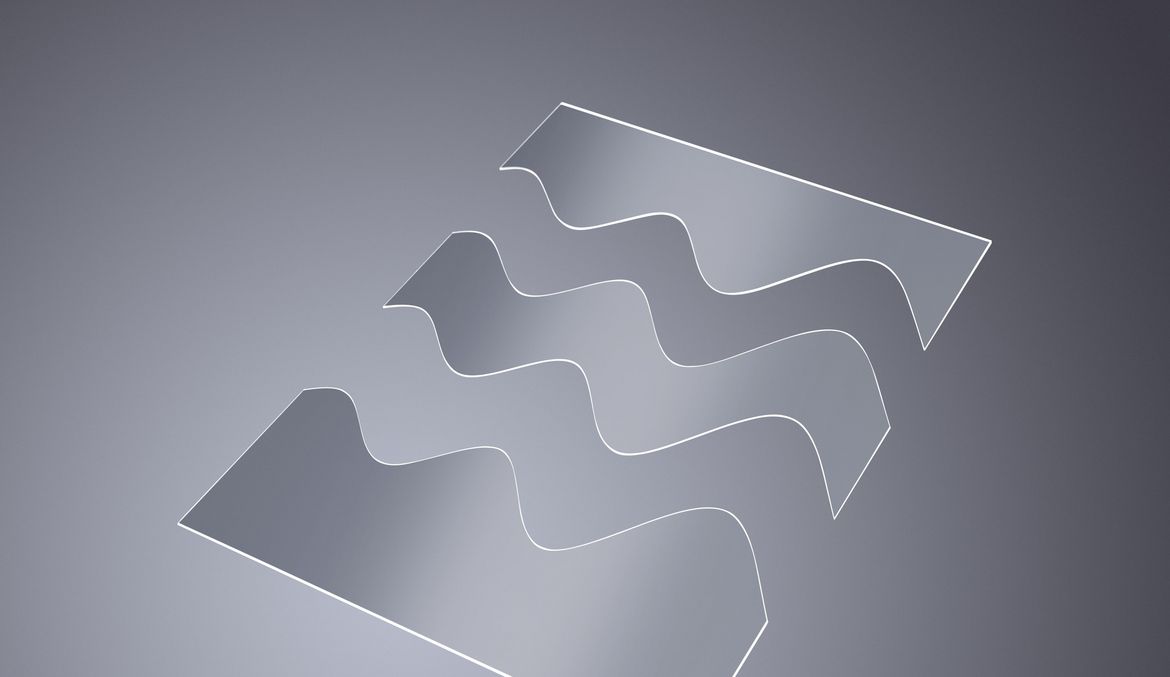

Flexible Geometrien

Mit dem Laser können Sie, im Gegensatz zu mechanischen Verfahren den verschleißfreien und berührungslosen Prozess auch für flexible zwei- und dreidimensionale Geometrien einsetzen. Die Pikosekundenlaser der TruMicro Serie 5000 sind dabei das perfekte Werkzeug.

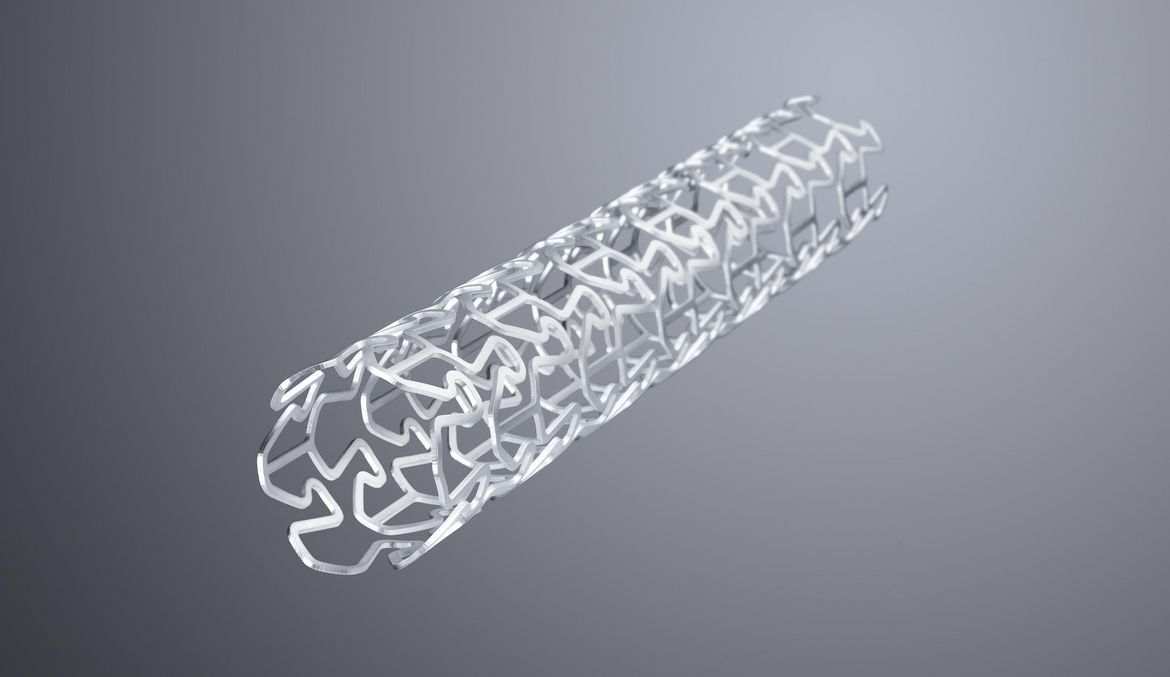

Lasergeschnittener Stent

Bei der Produktion von Stents kommt es entscheidend auf gratfreie Schnittflächen und Kanten an. Pikosekundenlaser erlauben eine nacharbeitsfreie Fertigung und erhöhen den Ertrag bei der Herstellung von Stents aus Nitinol. Die Ultrakurzpulstechnologie macht das Schneiden dieser bioresorbierbaren Stents aus der äußerst wärmeempfindlichen Formgedächtnis-Legierung erst möglich.

Hochpräzise Strukturierung von Saphir

Saphir schützt hochauflösende Kameras von Smartphones, dient bei der LED-Herstellung als Substrat und hochwertigen Produkten als Deckglas. Es ist äußerst beständig und extrem hart. Das macht es sehr schwierig, Saphir mit herkömmlichen Mitteln effizient ohne Risse zu bearbeiten. Mit einem Laser der TruMicro Serie 5000 erreichen Sie eine Qualität, die keine Nacharbeit erfordert.

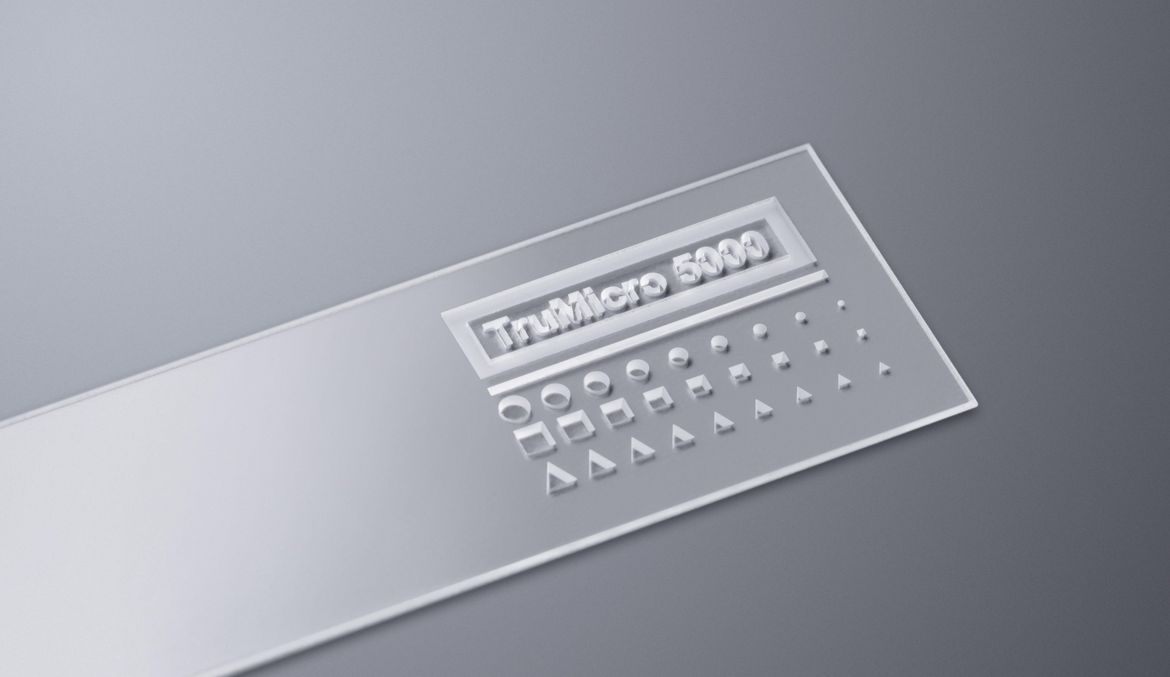

Lasergeschnittenes Saphirmuster

Mit den Pikosekundenlasern der TruMicro Serie 5000 können feine Geometrien qualitativ hochwertig geschnitten werden. Die hohe mittlere Leistung der Pikosekundenlaser sorgt zudem für höchste Produktivität.

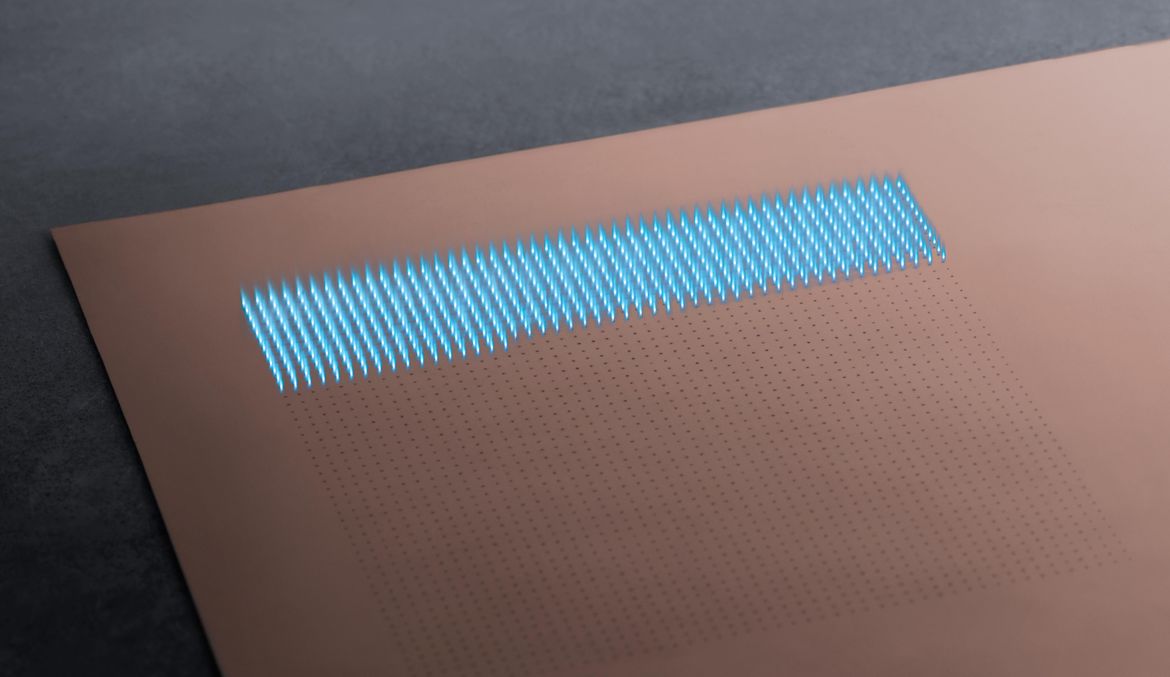

Leiterplatten bohren leicht gemacht

Moderne Leiterplatten sind mehrlagig aufgebaut und somit besonders kompakt. Mit Kupfer ausgekleidete Löcher verbinden die Leiterbahnen über die Ebenen hinweg. Dafür werden Löcher gebohrt, deren Durchmesser häufig weniger als 100 μm betragen. Die Pikosekundenlaser erledigen diese Aufgabe in nur einem Arbeitsgang. Die hohen verfügbaren Pulsspitzenleistungen ermöglichen die gewünschte Geometrie und Qualität – und das bei extrem hoher Produktivität.

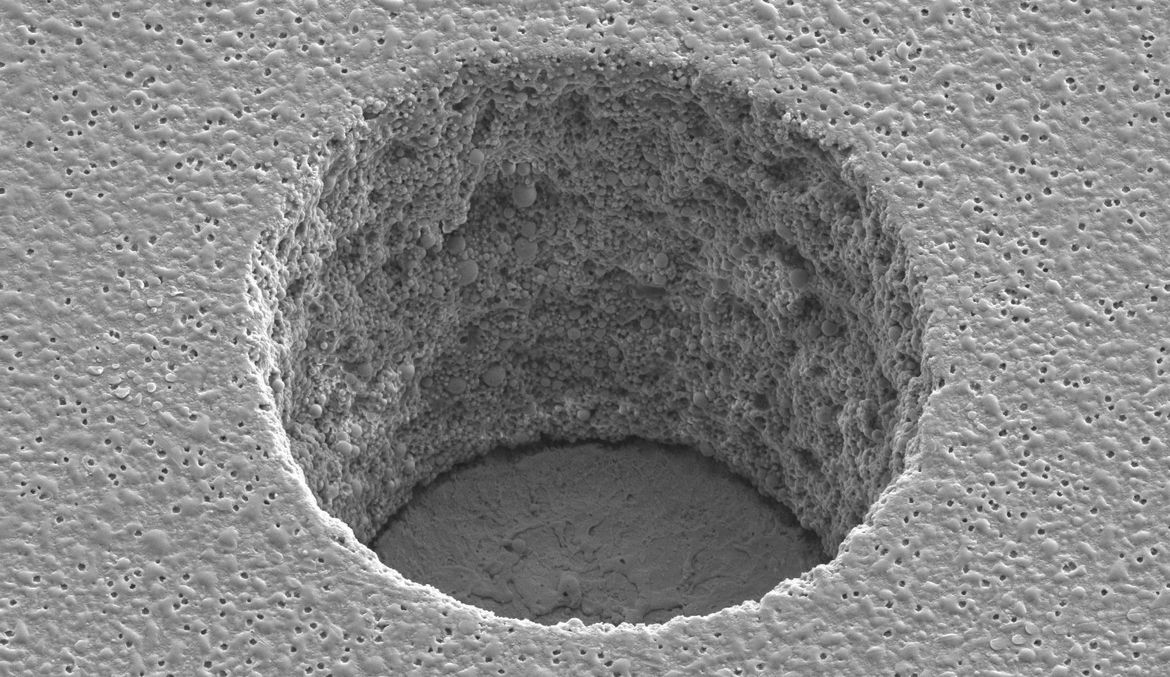

Mikrobohrung in Leiterplattensubstrat

In der Detailansicht einer Bohrung des Leiterplattensubstrats erkennt man in welch hoher Qualität die TruMicro Laser die Bearbeitung durchführen. Elementar hierfür ist die hohe verfügbare Pulsspitzenleistungen die zudem auch die Produktivität erhöht.

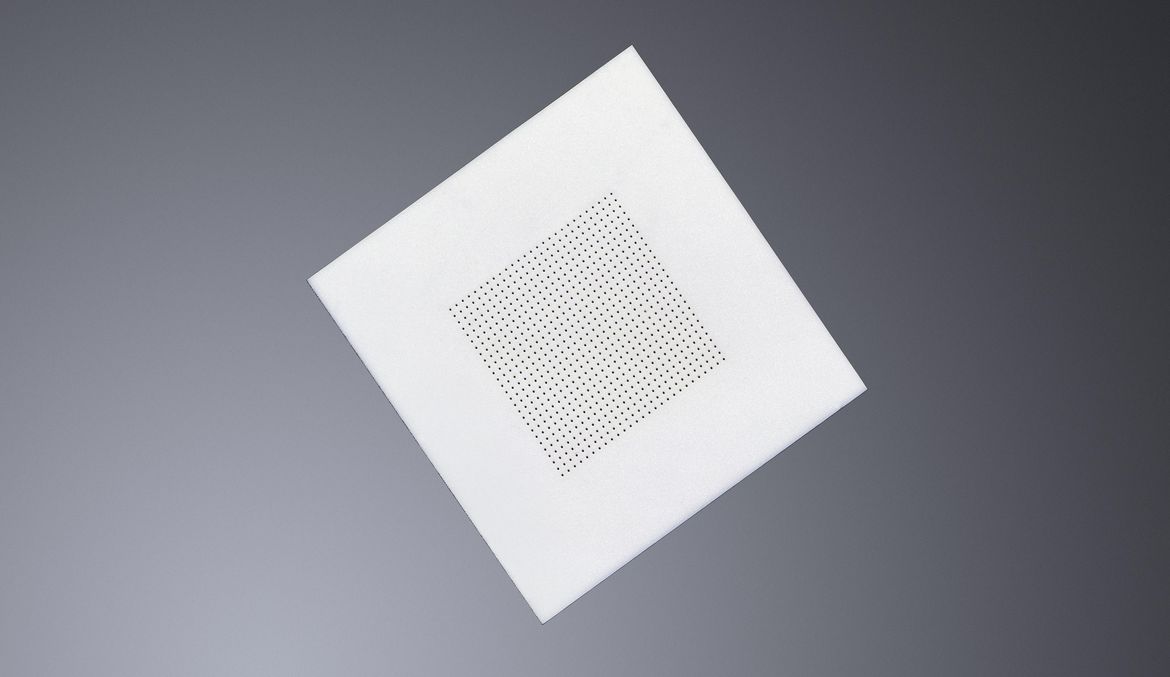

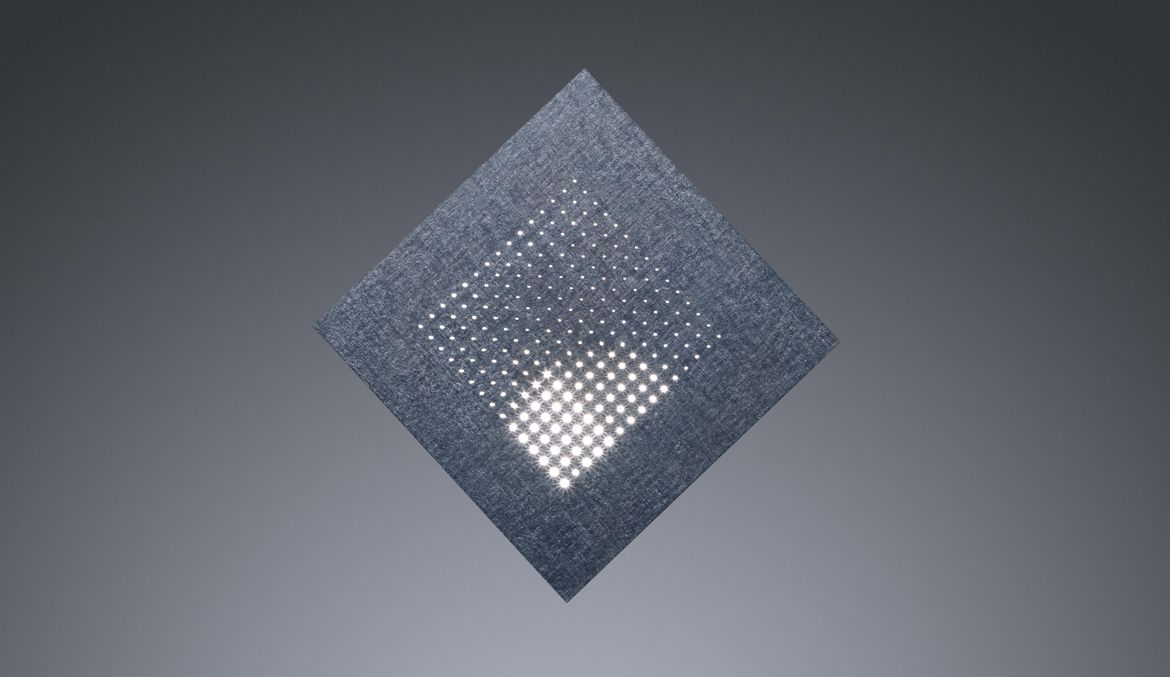

Laserbohrungen in einem Keramikplättchen

Gute elektrische Isolationseigenschaften und hohe Temperaturbeständigkeit machen technische Keramiken wie Aluminiumnitrid, Aluminiumoxid, Siliziumnitrid und Zirkoniumoxid zu vielseitig gefragten Materialien. Mit den Pikosekundenlasern erzeugen Sie in diesen Materialien Bohrungen mit kleinsten Durchmessern in hoher Qualität.

Laserbearbeitung sprödharter Materialien (Keramik, Glas, Saphir)

Mit den Lasern der TruMirco Serie 5000 können Sie sprödharte Materialien wie z. B. Keramik in hoher Qualität bearbeiten. Das Bohren und Schneiden von dünnen Keramiken ist dabei eine Domäne des Pikosekundenlasers. Sie erreichen mit seiner Hilfe kleinste Durchmesser in hoher Qualität.

Mikrobohrungen in dünnem Wolfram

Rasterförmig angeordnete Mikrobohrungen mit einem Durchmesser von ca. 70 Mikrometern in 0,2 Millimeter dünnem Wolfram.

|

TruMicro 5050

Produkt vergleichen

|

TruMicro 5070

Produkt vergleichen

|

TruMicro 5080

Produkt vergleichen

|

TruMicro 5250

Produkt vergleichen

|

TruMicro 5270

Produkt vergleichen

|

TruMicro 5280

Produkt vergleichen

|

TruMicro 5350

Produkt vergleichen

|

TruMicro 5370

Produkt vergleichen

|

TruMicro 5380

Produkt vergleichen

|

|

|---|---|---|---|---|---|---|---|---|---|

| Laserparameter | |||||||||

| Mittlere Ausgangsleistung | 50 W | 100 W | 150 W | 30 W | 60 W | 90 W | 15 W | 30 W | 45 W |

| Strahlqualität (M²) | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional |

| Wellenlänge | 1030 nm | 1030 nm | 1030 nm | 515 nm | 515 nm | 515 nm | 343 nm | 343 nm | 343 nm |

| Pulsdauer | < 10 ps | < 10 ps | < 10 ps | < 10 ps | < 10 ps | < 10 ps | < 10 ps | < 10 ps | < 10 ps |

| Max. Pulsenergie | 500 µJ | 500 µJ | 250 µJ | 150 µJ | 150 µJ | 150 µJ | 75 µJ | 75 µJ | 75 µJ |

| Min. Repetitionsrate | 100 kHz | 200 kHz | 600 kHz | 200 kHz | 400 kHz | 600 kHz | 200 kHz | 400 kHz | 600 kHz |

| Max. Repetitionsrate | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz |

| Bauform | |||||||||

| Abmessungen Laserkopf (B x H x T) | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm |

| Abmessungen Versorgungsgerät (B x H x T) | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm |

| Aufstellung | |||||||||

| Schutzart | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 |

| Umgebungstemperatur | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C |

|

TruMicro 5050

|

TruMicro 5070

|

TruMicro 5080

|

TruMicro 5250

|

TruMicro 5270

|

TruMicro 5280

|

TruMicro 5350

|

TruMicro 5370

|

TruMicro 5380

|

|

|---|---|---|---|---|---|---|---|---|---|

| Laserparameter | |||||||||

| Mittlere Ausgangsleistung | 50 W | 100 W | 150 W | 30 W | 60 W | 90 W | 15 W | 30 W | 45 W |

| Strahlqualität (M²) | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional | < 1,3 Standard, M² < 1,2 optional |

| Wellenlänge | 1030 nm | 1030 nm | 1030 nm | 515 nm | 515 nm | 515 nm | 343 nm | 343 nm | 343 nm |

| Pulsdauer | < 10 ps | < 10 ps | < 10 ps | < 10 ps | < 10 ps | < 10 ps | < 10 ps | < 10 ps | < 10 ps |

| Max. Pulsenergie | 500 µJ | 500 µJ | 250 µJ | 150 µJ | 150 µJ | 150 µJ | 75 µJ | 75 µJ | 75 µJ |

| Min. Repetitionsrate | 100 kHz | 200 kHz | 600 kHz | 200 kHz | 400 kHz | 600 kHz | 200 kHz | 400 kHz | 600 kHz |

| Max. Repetitionsrate | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz | 1000 kHz |

| Bauform | |||||||||

| Abmessungen Laserkopf (B x H x T) | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm | 680 mm x 289 mm x 1060 mm |

| Abmessungen Versorgungsgerät (B x H x T) | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm | 442 mm x 1192 mm x 910 mm |

| Aufstellung | |||||||||

| Schutzart | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 |

| Umgebungstemperatur | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C | 20 °C - 30 °C |

Die technischen Daten aller Produktvarianten als Download.

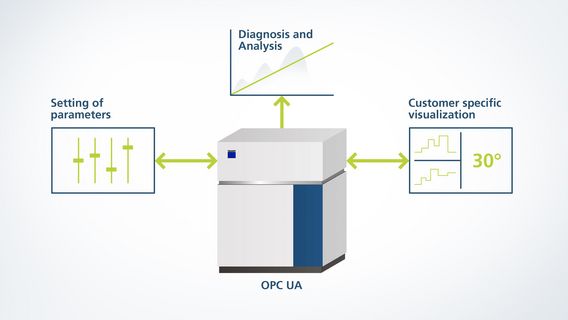

TruControl

TruControl ist die schnelle und einfach bedienbare Steuerung für TRUMPF Festkörperlaser. Sie regelt die Laserleistung in Echtzeit für reproduzierbare Ergebnisse. TruControl verwaltet, steuert und visualisiert die Schnittstellenbelegung. Sie profitieren von einer einheitlichen Steuerungsarchitektur über alle Lasertechnologien hinweg. Die Laser verfügen über Schnittstellen zur Ansteuerung von intelligenten TRUMPF Optiken, z.B. der überwachten Fokussieroptik CFO oder der Scanneroptik PFO. Die Programmierung der Bearbeitungsoptik erfolgt bequem über die Lasersteuerung. Mit Remote Support von TRUMPF erhalten Sie außerdem in wenigen Sekunden per Fernwartung Unterstützung. Dadurch können Serviceeinsätze verhindert oder bestmöglich vorbereitet werden und die Verfügbarkeit des Lasergeräts steigt.

Mit nützlichen Zusatzoptionen arbeiten Sie noch effizienter und prozesssicherer mit den Lasern der TruMicro Serie 5000

Für die Integration eines TruMicro Lasers in Ihre Maschine oder Fertigungslinie sind die Schnittstellen entscheidend. Daher bieten Festkörperlaser von TRUMPF Schnittstellen zu allen gängigen Feldbussystemen. Weiterhin sind erhältlich: Echtzeitschnittstelle, Parallel Digital I/O, Schnittstelle für Prozesssensorik, OPC UA Softwareschnittstelle, analoge Eingangskarte, Schnittstelle für intelligente TRUMPF Optiken (CFO, PFO).

Im Störungsfall greifen TRUMPF Serviceexperten über eine sichere Remote-Verbindung aktiv auf Ihren Laser zu. Häufig wird so die Störung direkt behoben oder die Konfiguration des Lasers so verändert, dass Sie bis zum Eintreffen des Ersatzteils weiter produzieren können.

TRUMPF bietet Ihnen alle Komponenten, die Sie zur Strahlführung vom Laser bis zum Werkstück benötigen. So auch diverse Fokussieroptiken, die sich in vielen Jahren industriellen Einsatzes als präzise und zuverlässig bewährt haben. Die Optiken sind leicht integrierbar – sowohl in Stand-Alone-Bearbeitungsstationen als auch in kompletten Fertigungslinien. Der modulare Aufbau ermöglicht es die Optiken stets an den Lasertypen sowie an die unterschiedlichen Bearbeitungssituationen anzupassen.

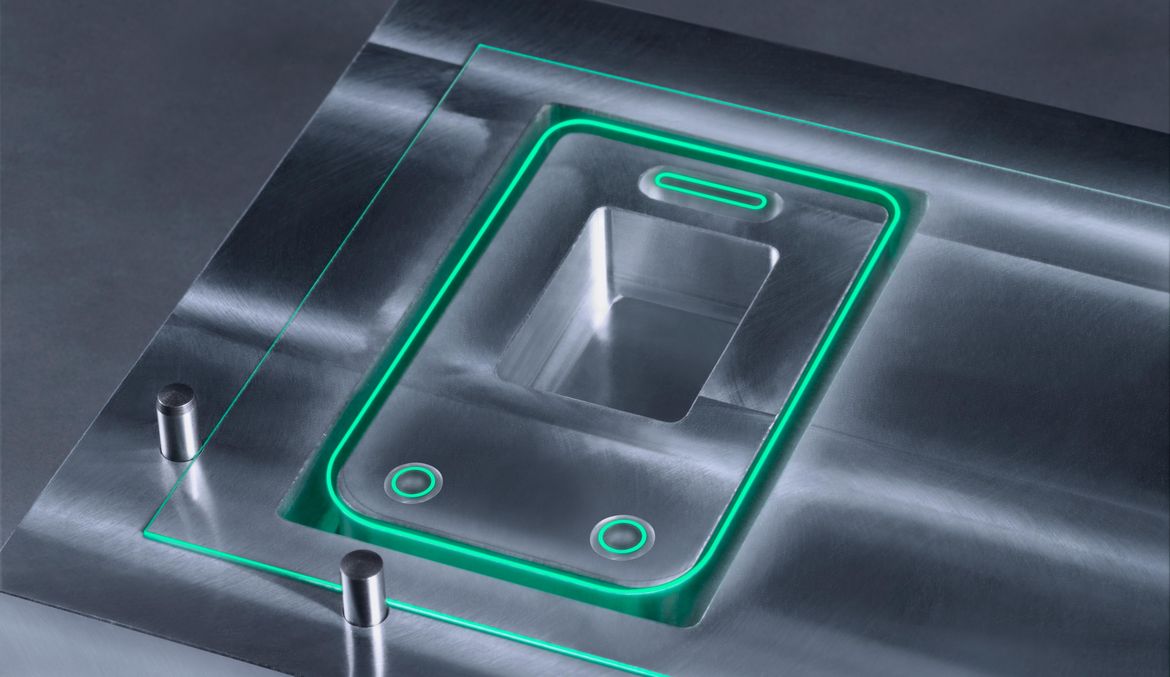

TOP Cleave Schneidoptik

Die Fokussieroptik TOP Cleave-2 ist eine Bearbeitungsoptik zum hochdynamischen Schneiden von transparenten Materialien wie Glas oder Saphir.

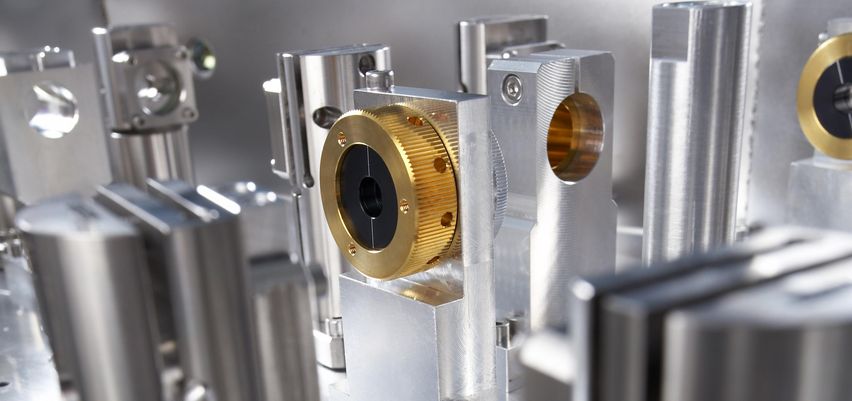

Ultrakurze Laserpulse sind nicht nur ultrakurz, sie erreichen auch bei Pulseigenschaften wie Energie und Leistung Spitzenwerte. Damit trotz dieser Spitzenintensitäten am Werkstück auch genau der richtige Puls ankommt, sind spezielle Strahlführungs- und -formungselemente gefordert. TRUMPF verfügt über Strahlweichen, Umlenker, Strahlaufweitungen und Polarisationsoptiken, die für den Einsatz mit Ultrakurzpulslasern optimiert sind.

TruMicro Umlenker sind geeignet für ultrakurze Laserpulse zur Führung des Laserstrahls unter Beibehaltung der Pulsparameter.

Durch Strahlteilung können zwei Lichtwege gleichzeitig mit jeweils der Hälfte der Laserleistung versorgt und zwei Werkstücke gleichzeitig bearbeitet werden. Die mechanische Einstellung erlaubt die Anpassung der geteilten Leistung auf die exakte Gleichverteilung der Leistung in beiden Strahlarmen.

Durch Strahlweichen kann Laserlicht alternativ in zwei Lichtwegen zu unterschiedlichen Werkstücken geführt werden. Der Pilotlaser ermöglicht die einfache Justage des Strahlengangs.

Zirkular polarisiertes Licht wird aus linear polarisiertem Licht mittels einer Viertelwellenplatte erzeugt und ermöglicht bei Applikationen mit richtungsabhängigen Fertigungsgeometrien gleichmäßige Bearbeitungsergebnisse.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.