Solutions

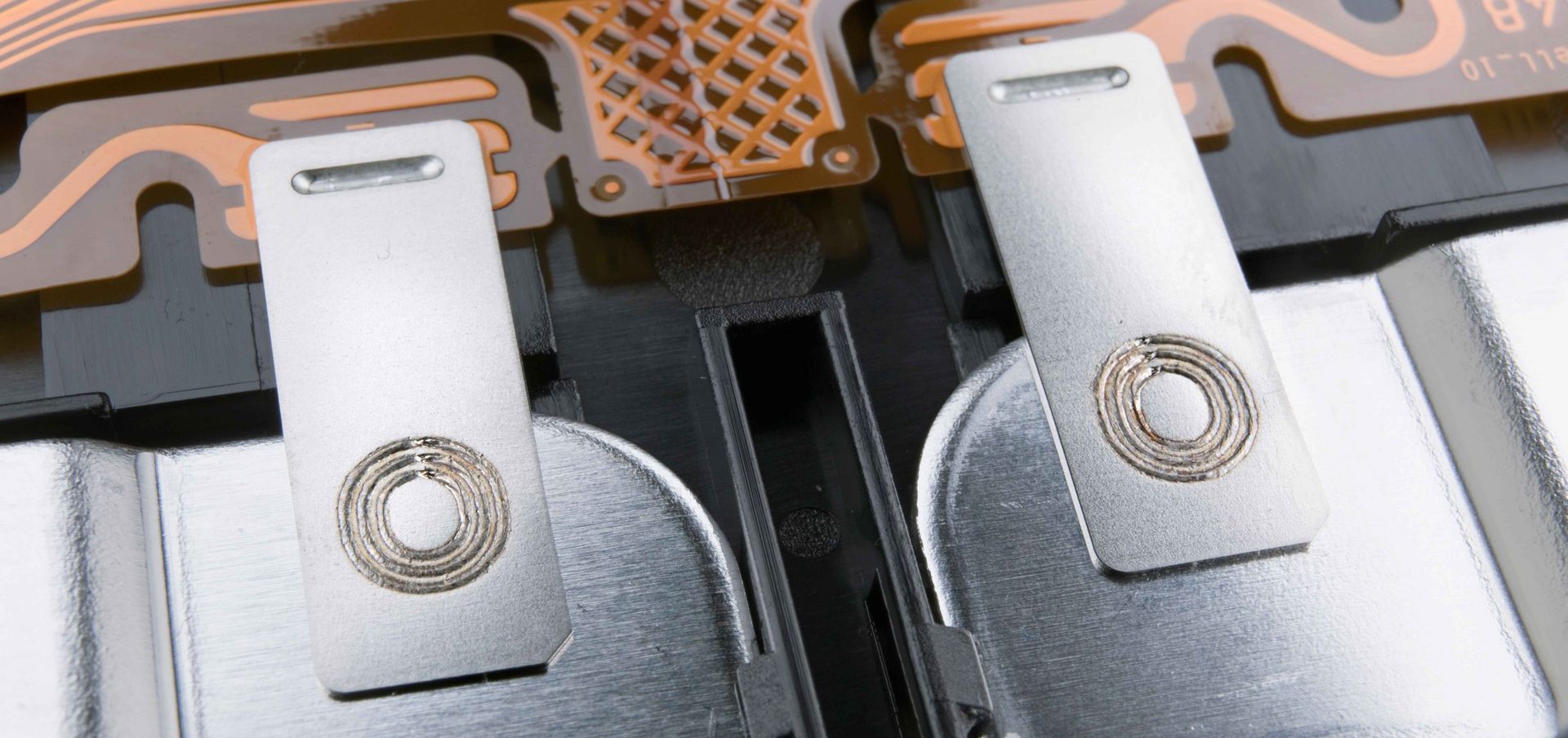

On a visit to the TRUMPF Laser Application Centre, Daniel Weller learned about a new development in the field of detection systems. "We previously worked with TRUMPF's VisionLine Detect image processing, which proved invaluable when it came to traditional cell contacting systems (CCS)", he explains. However, TRUMPF's cloud-based EasyModel AI training platform is taking performance to the next level. The combination of EasyModel AI and the AI filter option for TRUMPF's VisionLine Detect image processing system detects variable ambient conditions, component reflections, changing lighting situations and fluctuations in material properties. "Shortly after TRUMPF officially launched EasyModel AI, we were awarded a contract for a complex cell contacting system that entailed significant challenges due to its two-metre length and 50 welding positions. EasyModel AI came along at just the right time," says Weller.

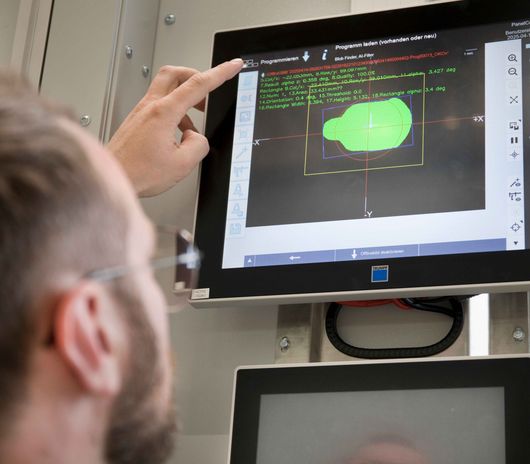

EasyModel AI is a tool that enables users without any programming knowledge to create and train their own image-based AI models to fit components precisely. "Firstly, we simply use VisionLine Detect to take images of the segments of the component where welding positions need to be set. We store the images using Quality Data Storage, and we can then upload them to EasyModel AI, which is easily accessible through our MyTRUMPF platform", Weller explains. Once a project has been created, Weller and his colleagues mark the welding positions to be detected on the images. The AI then starts its analysis and calculates a model. The operator can then optimise the model intuitively step by step. Only a few training images are needed to create a functional AI model. Once a satisfactory model is achieved, it is transferred to the production line. The AI filter option for VisionLine Detect is employed there, accurately distinguishing between relevant image areas and other elements like fixtures, dirt or reflections. "The difference between VisionLine Detect with and without an AI filter is very clear at this point," says Weller. "The AI filter creates a binary image, i.e. in black and white only. The detected component is displayed in white, while the surrounding areas appear in black. This allows the edge detection algorithms to easily identify the welding area to be detected." Previously, Weller and his team used TRUMPF's VisionLine Detect image processing system with position-dependent laser exposure. This was specifically adjusted to identify the respective positions reliably. The process had to be individually adapted to the respective position in the processing field to compensate for the different reflections from the component surfaces. The process was time-consuming and subject to numerous influencing factors; moreover, it had to be performed separately for each component position.

Implementation

To implement the new solution, ElringKlinger simply needed to activate the EasyModel AI option with the AI filter and complete a brief introductory phase. "During commissioning of the pre-series system directly on the component, TRUMPF employees supported us throughout every step of the process," says Weller. "After just an hour or two, we had our first component ready." If any uncertainties crop up today, TRUMPF experts quickly resolve them remotely or in Teams meetings. Collaboration is made easier with TRUMPF's Quality Data Storage, which is used to store and save files, and even share them with TRUMPF's specialists if required.

For Weller, the simplicity of the training process is one of the main advantages of EasyModel AI: "We need hours rather than days to achieve good results." It is also important that no prior knowledge is needed to achieve good results. "This becomes vital once series production is underway and our less experienced colleagues at the sites need to make minor adjustments. The system operates on a 'what-you-see-is-what-you-get' principle, making it easy to understand even for those without programming experience," says Weller. The ability to make minor adjustments is also an advantage for Weller and his colleagues: "Every CCS is structured differently, but sometimes the differences are only minimal. With the help of AI, we can now use existing training images of CCS as the basis for new models by simply retraining to accommodate minor deviations. This further accelerates the development phase."