TRUMPF VisionLine image processing prevents errors in components. Camera-based image processing means you can monitor all aspects of cutting and welding applications. VisionLine detects the position of the components automatically and transmits this information to the control system. The sensor-based 3D information generated can be used for positioning and for checking component characteristics, such as the height difference of secondary components.

EasyModel AI

Variable ambient conditions such as dirt on the fixture, reflections from the component or changing lighting situations make characteristics recognition for positioning the laser beam more difficult. The solution can be found in artificial intelligence. EasyModel AI is a cloud-based AI training platform that you can use to label data easily, with no prior programming knowledge required. A small amount of training data is sufficient for powerful AI models, which you can use with the AI filter option for VisionLine Detect. Discover the difference and enjoy the benefits of EasyModel AI combined with TRUMPF image processing.

EasyModel AI reduces dependence on external factors

The combination of EasyModel AI and the AI filter option for TRUMPF VisionLine Detect image processing enables you to satisfy the stringent requirements of series production in terms of quality and cycle time. This makes your production processes even more efficient and robust against external factors! EasyModel AI improves characteristics recognition and detects precise disruptive factors such as shadows, dirt or reflections.

The interaction between EasyModel AI and the AI filter option in VisionLine Detect means that manufacturing is significantly less dependent on part quality and changing lighting conditions.

Standardised algorithms ensure that measurement processes are always verifiable. This enables you to retain full control of you data.

EasyModel AI enables you to handle challenging lighting or part situations such as burrs, scratches or dirt.

Maximise your production productivity with the highest detection rates.

The AI model can be adapted to any application – simple retraining is also possible.

Just a few labelled training images suffice for the development of high-performance AI models.

How to optimise your production processes with EasyModel AI

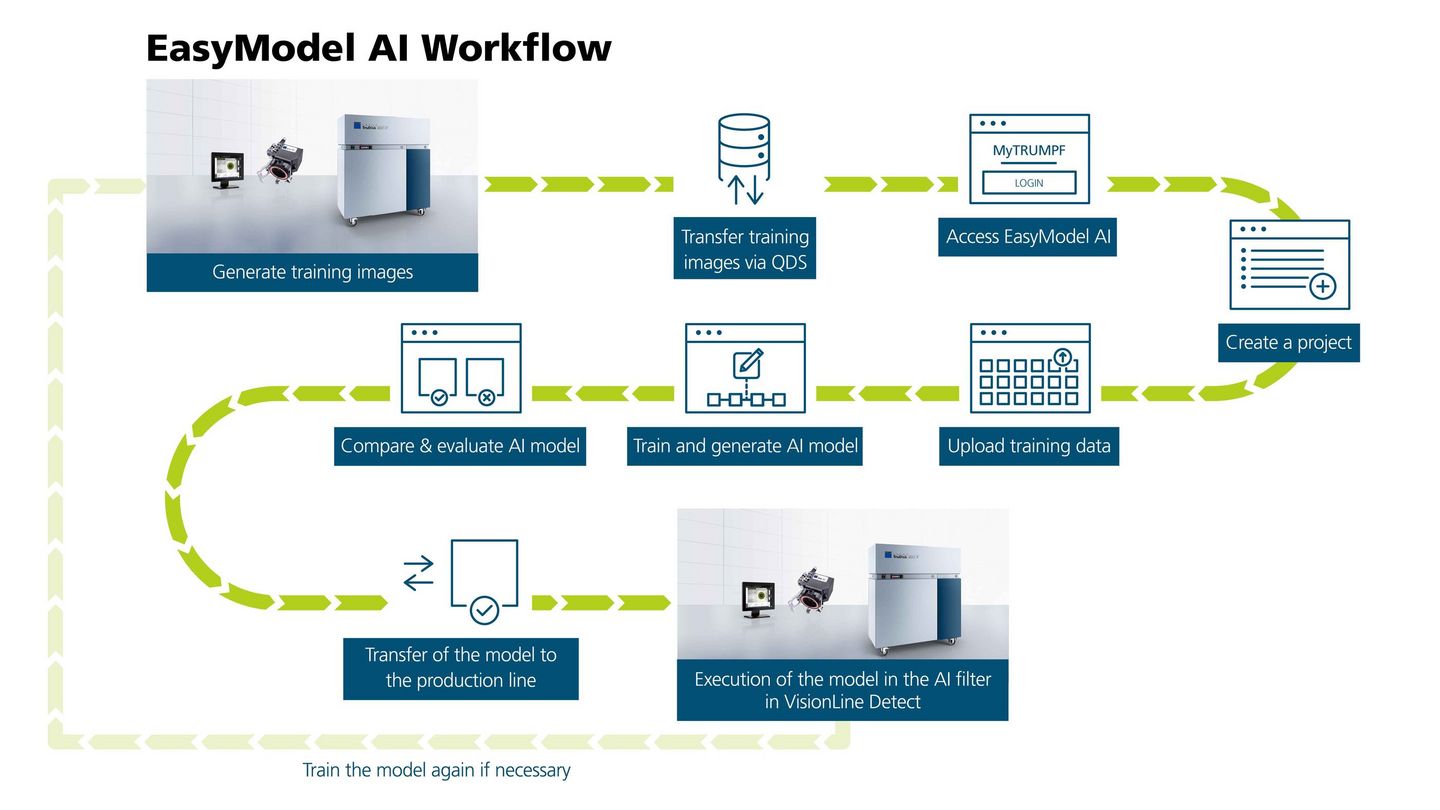

In a step-by-step process, you generate training images, transfer them to the cloud and create a new project under EasyModel AI. Based on this data, an AI model is trained by marking relevant part areas in images and exporting the model. This model is used in the production system for VisionLine Detect image processing after being evaluated and implemented in production. Now there is nothing to stop the model and the AI filter option being implemented!

Typical applications that benefit from AI

Sensor system – VisionLine Detect

![[Translate to en_GB:]](/filestorage/TRUMPF_Master/_processed_/b/2/csm_Condition-monitoring-center-laser-technology_9d6391eb7b.jpg)

![[Translate to en_GB:]](/filestorage/TRUMPF_Master/_processed_/4/2/csm_Smart-View-Keyvisual-169_208984fee6.jpg)