For Robert Bloos, industrial innovation starts at work, not in the conference room. When he climbs into his excavator cab in the early morning sunlight, he takes his role seriously – because change starts with having the right attitude. Bloos is the CEO of Heizomat, a family-run SME in Gunzenhausen, Germany, which builds heating systems fueled by woodchips. For decades, it has been helping farmers, municipalities and organizations make the switch to heating with renewable energy sources, offering robust, carbon-neutral solutions that break the dependency on fossil fuels.

Now Bloos hopes to go one step further by showing how industrial production can be both sustainable and economically viable at the same time. A few kilometers down the road from Heizomat’s headquarters, the company is building its Green Smart Factory. This is no mere showpiece; it is a fully fledged production site that aims to set new standards in the industry for energy independence, digitalization and sustainable industrial production.

Working closely with TRUMPF as a technology partner, Heizomat completely reworked and rebuilt its entire production process. The partnership is the perfect combination of high tech solutions and a can-do attitude. Bloos has long sought to expand beyond his traditional customer base, and the new factory is designed to appeal not only to farmers and municipalities, but also to industrial customers keen to deploy self-sufficient, tried-and-tested energy systems.

Heizomat is determined to break out of its current niche. With years of experience at putting customers first, the company has built up an outstanding reputation for the quality, durability and practicality of its woodchip heating systems. Now Bloos is ready to take the next step by showing how his Green Smart Factory can combine sustainability and smart connectivity within a successful SME environment.

Going all in

Bloos understands that industrial manufacturers need to be confident in the plans they make. Few producers would feel comfortable switching to a new energy supply that hasn’t been thoroughly tested. That’s why he has taken the first step by showcasing how it can work in practice. The Green Smart Factory is the perfect example of how energy-self-sufficient production is technically and economically feasible on an industrial scale. Heizomat is transferring its entire sheet metal, round tube, and machining processes to the new building to show how sustainability and profitability can go hand in hand – with digitalization as the enabling technology.

“The Green Smart Factory has three defining characteristics,” says Bloos. “Its energy supply, its state-of-the-art machinery and the software that holds everything together.” It’s all based on the straightforward principle that production should adapt to the energy that’s available – not the other way around.

Planning ahead

Bloos calls this an “energy-led” system, and its key characteristics are as follows: all the factory’s energy requirements are covered by sun, wind and wood, and integrated systems supply the production facilities with electricity, heat and even cooling. A woodchip heating system, together with a wood gasifier, forms the heart of Heizomat. The wood gasifier supplies both heat and valuable electricity – around the clock. Heizomat makes its own fuel on site: a pallet chipper turns delivery pallets – like the ones sheet metal arrives on – into woodchips. What looks like waste is instead transformed into a valuable energy source that keeps the plant fed with sustainable heat.

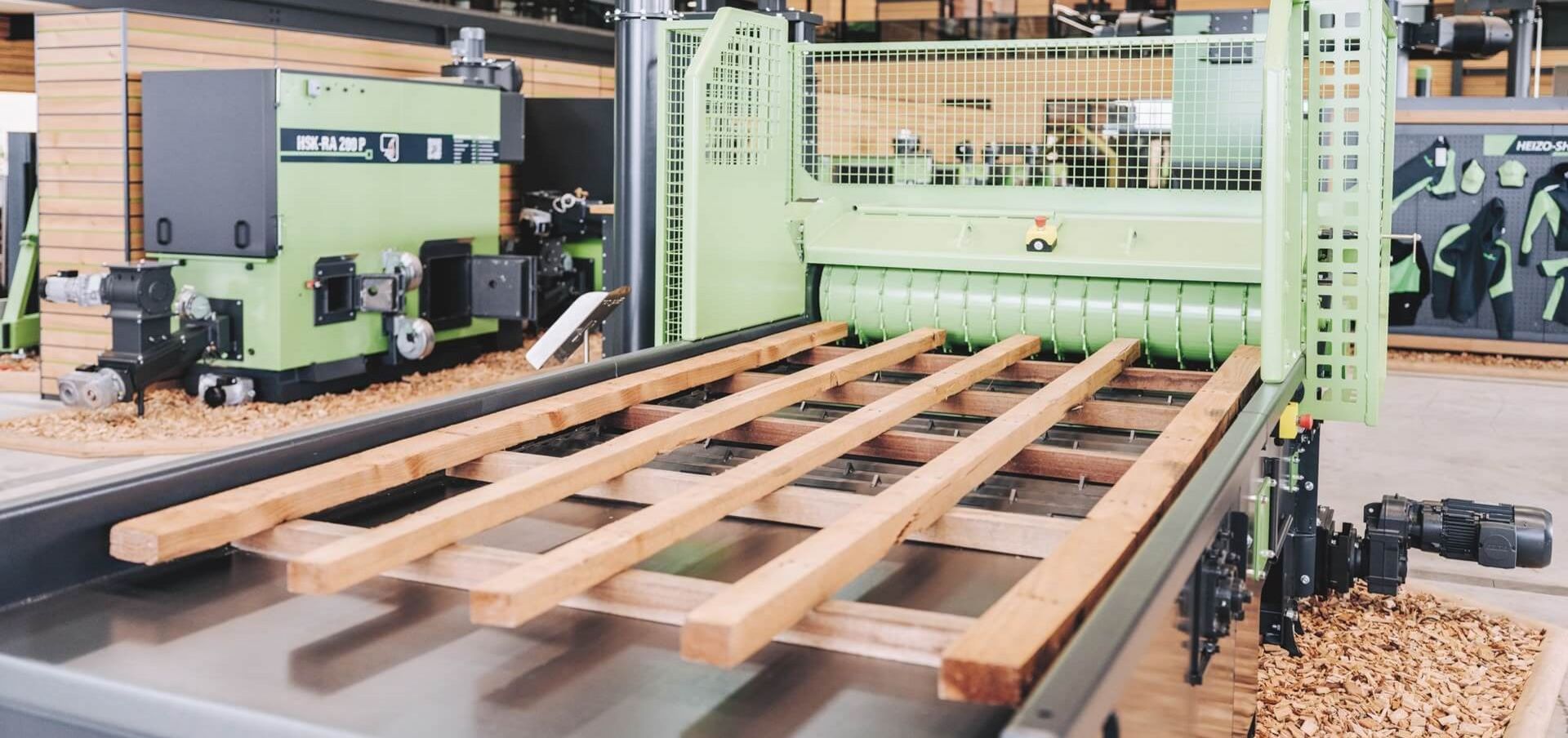

Every last detail was considered in Heizomat’s plans: the hall’s heat distribution system operates with high efficiency – with integrated lighting included. This, too, is part of the driving concept of not merely shifting resource use, but actually reducing it. And there’s plenty of other smart things going on beneath the surface. Production is automated, and control systems are intelligently networked. The machinery line-up, which was planned in collaboration with TRUMPF, includes various TruArc Weld 1000 welding cells, TruBend 5000 and 8000 bending machines, and laser cutting machines such as the TruLaser 3030 and 5040 and the STOPA storage system. All this can be planned and managed via TRUMPF’s Oseon software, which integrates seamlessly with the in‑house ERP that coordinates operations. Materials, data and energy come together in an intelligent, efficient and continuous flow.

Six additional partner companies are involved in the project, ranging from energy and building technology to automation solutions – and they are all delighted with the opportunities the Green Smart Factory offers. They can use the production hall as a showroom to demonstrate real‑world production processes to their customers – a huge advantage in an era of digitally connected manufacturing, says Bloos: “Most companies still just show their customers individual machines, but what matters is how it all works together.”

Bloos sees his new plant not as a showpiece, but as a strategic necessity. Real independence requires preparation, which is why Heizomat is careful to build up enough woodchip reserves to last a whole year, as well as large quantities of metal sheets. On principle, it produces as much as it can in-house, because certainty doesn’t come from words or declarations of intent, but from actions. “Farmers cut enough wood to last a couple of years and stack it in their yards. That’s how we think, too,” says Bloos.

He applied the same mindset when it came to financing the new factory, drawing on solid reserves instead of running any risks with outside capital. For Bloos and his team, it’s all about planning ahead, which is why Heizomat can hold a stable course in a crisis when others falter. The company also strives for a genuinely circular economy. The woodchips come from the local region, often from trees that have to be felled anyway, such as along highways. What others perceive as waste, Heizomat sees as a valuable resource. And the benefits stay local thanks to short distances, clear accountability and a strong identity.

The choice of machinery was equally deliberate. Heizomat’s close partnership with TRUMPF is designed to boost productivity while easing the strain on workers. Back‑breaking tasks such as manually bending sheet‑metal parts are very much a thing of the past. The machines slot seamlessly into the overall digital concept, and what used to be documented on paper is now controlled, recorded and analyzed in an automated system.

Innovating by doing

At Heizomat, improvements don’t come as theories off a drawing board. Bloos trusts his instincts and listens carefully to his team to make sure new ideas, solutions to problems and other feedback are directly incorporated in the ongoing development of his machines. If a machine fails to perform reliably in day-to-day operations or is cumbersome to operate, then the situation is rectified immediately. Suggestions for improvement sometimes take just days to implement.

This isn’t the kind of place where you’ll find a traditional R&D department. Bloos favors pragmatism over process, and craftsmanship over glossy strategy presentations. He encourages his employees to get creative. “Don’t talk, act!” has been something of an unofficial company motto for years, Heizomat’s very own version of “carpe diem”. Many of Bloos’s team members work with the company’s products themselves, whether on service call-outs, on the assembly line or at home. Their feedback stems directly from day-to-day production, and this close proximity to the product is deeply rooted in the company’s DNA. Robert Bloos Sr., Heizomat’s founder, ran the business in line with his principles of better solid than speculative – and better grounded than grandiose. His son has maintained that philosophy with an open and practical culture of innovation.

Whether on the farm, in the cab of an excavator or at his desk, Robert Bloos believes that the future begins by embracing responsibility and finding the courage to take the first step. But even a pragmatist like him thinks strategically, and Japan and the USA are next on his list. Beyond its deep tech focus, these markets also offer ways to reduce reliance on Europe, and Heizomat is now exploring its international options even as it maintains its roots in the region. At some point, Bloos says, his son might take the helm at Heizomat. The eleven-year-old enjoys watching his father at work and helping out at the company, but the path he ultimately chooses is up to him. “He needs to chart his own course,” says Bloos – just like his father did before him.