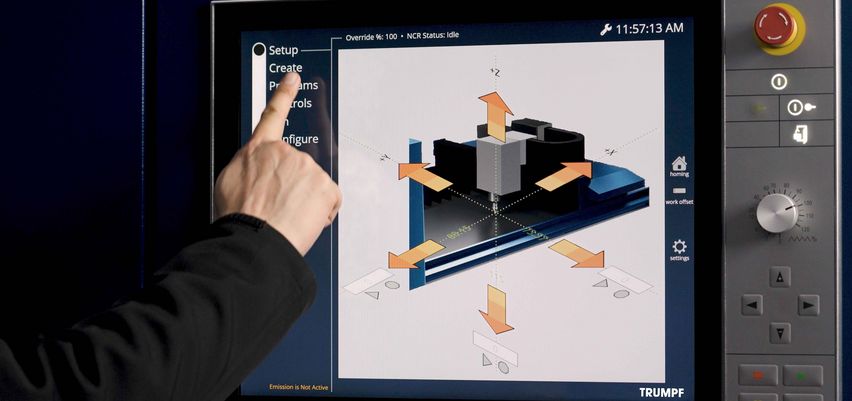

The Easy Programming software stands for a new operating philosophy: It guides you intuitively through the process. Program your machine quickly and easily directly on the user-friendly HMI panel on the machine or via offline programming from the office. Thanks to the included real time preview you can track each change and are in full control of a perfect cutting result.

Economic reliable machine

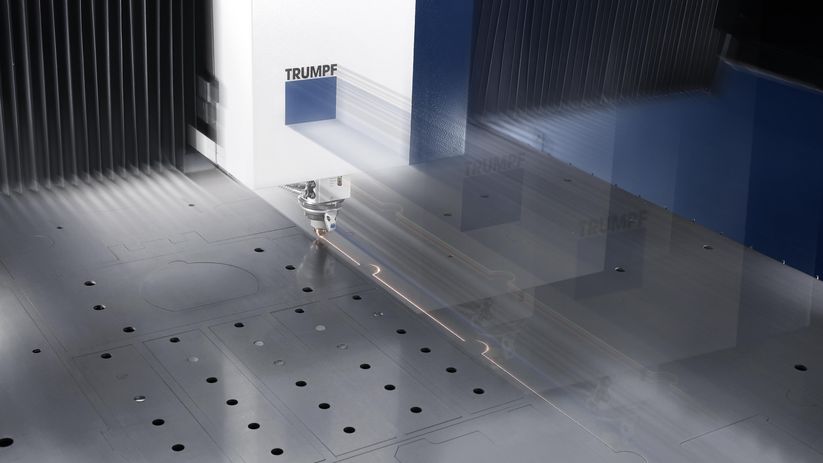

The TruLaser Series 1000 Basic Edition is the ideal start into the world of high-quality laser cutting. It is equipped with a TruFiber laser for cutting a wide range of sheet thicknesses. The intuitive programming system makes it possible to start production quickly. In addition, we are always on hand to lend our support: You can count on our experienced and competent service team to answer all your questions regarding maintenance and applications.

Thanks to the intuitive design and the Easy Programming software with integrated cutting data, you can get started right away.

High-quality components and production according to TRUMPF Quality Standard guarantee safe operation.

Stable results thanks to optimal machine design.

You can rely on TRUMPF Remote Service, fast technical support and professional training offers

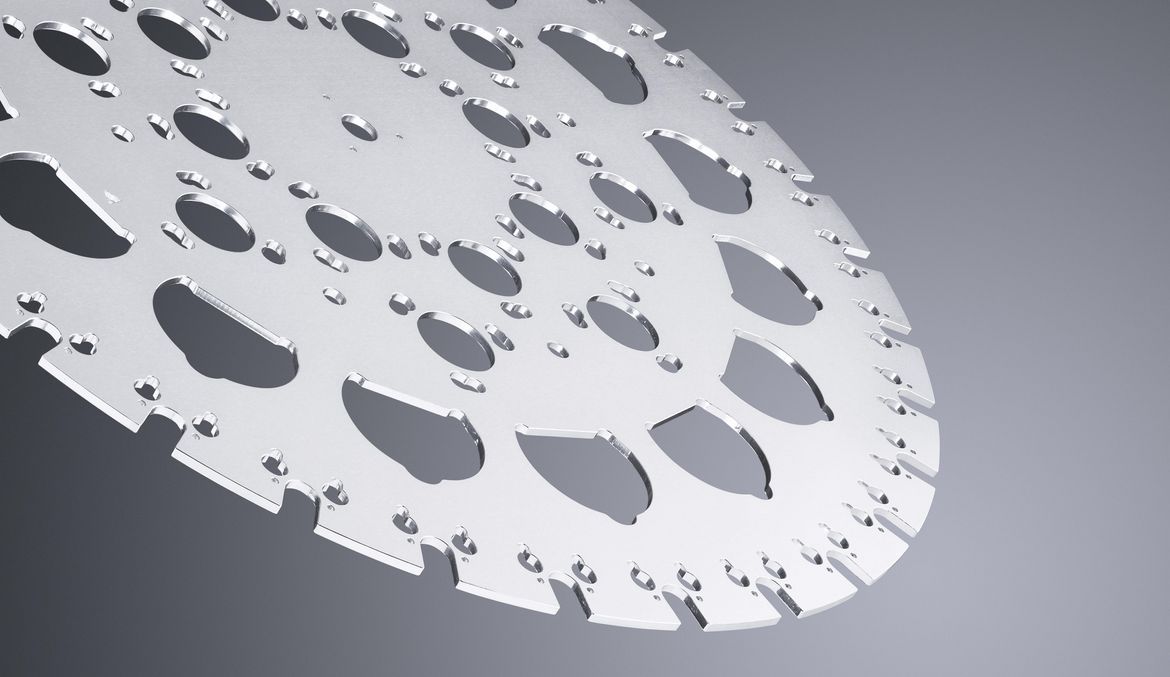

The TruLaser Series 1000 Basic Edition cuts a wide range of sheet thicknesses (1 - 25 mm).

The TruLaser Series 1000 Basic Edition is especially productive at processing thin sheets of stainless steel and mild steel in a fusion cutting process. You can also use the machine to cut aluminum, brass, copper or laminated stainless steel in a fast and reliable manner.

You can even use nitrogen to cut copper with the TruLaser Series 1000 Basic Edition.

|

TruLaser 1030 Basic Edition

|

|

|---|---|

| Dimensions | |

| Length | 10700 mm |

| Width | 7300 mm |

| Height | 3100 mm |

| Weight | |

| Weight of basic machine | 9400 kg |

| Working range | |

| X axis | 3000 mm |

| Y axis | 1500 mm |

| Laser-specific data - TruFiber 3001 | |

| Maximum laser power | 3000 W |

| Maximum sheet thickness, mild steel | 20 mm |

| Maximum sheet thickness, stainless steel | 16 mm |

| Maximum sheet thickness, aluminum | 16 mm |

| Maximum sheet thickness, copper | 6 mm |

| Maximum sheet thickness, brass | 6 mm |

| Laser-specific data - TruFiber 6001 | |

| Maximum laser power | 6000 W |

| Maximum sheet thickness, mild steel | 25 mm |

| Maximum sheet thickness, stainless steel | 25 mm |

| Maximum sheet thickness, aluminum | 25 mm |

| Maximum sheet thickness, copper | 10 mm |

| Maximum sheet thickness, brass | 10 mm |

The technical data of all product versions as a download.

Simple operation

Cutting parameters for all materials and sheet thicknesses are stored in the machine software. TRUMPF experts have developed and rigorously tested the parameters – meaning TRUMPF laser cutting expertise is included in your machine.

Process reliability and operator support

Reflections occurring when cutting non-ferrous metals – such as copper and brass or galvanized sheet metal and film-coated stainless steel – can damage your laser. You don’t need to worry about that when using TRUMPF lasers: they are designed to cut non-ferrous metals as reliably as you are accustomed to with stainless steel, mild steel and aluminum.

Clean protective glass ensures high cut quality. To ensure this high standard, TRUMPF cutting unit comes with a sensor that manually monitors the condition of the protective glass. Therefore, you only need to clean and replace the glass when detected contamination, saving you time and costs.

Productivity

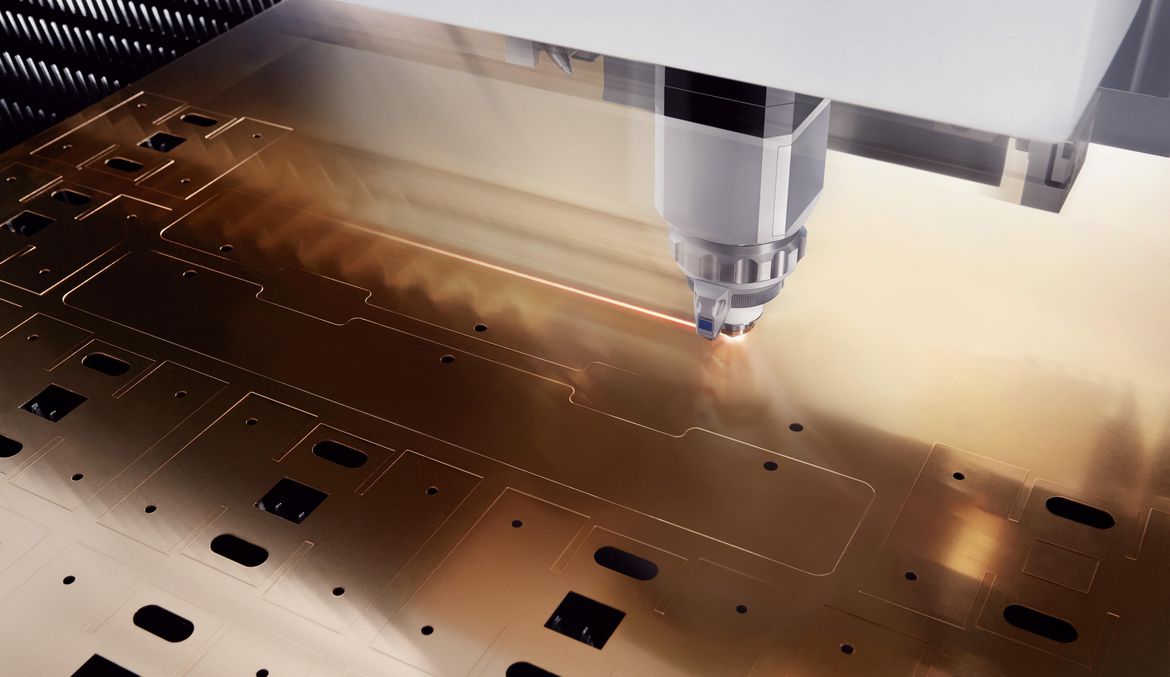

Quick and economic – without compromising on quality: With Highspeed, you can set new records with the solid-state laser when it comes to cutting with nitrogen. As a result, you may almost double your sheet throughput for medium and thick mild steel and stainless-steel sheets. It is also possible to double the feed rate. A special nozzle design also reduces your cutting gas consumption by up to 40%, and even prevents burr formation on contours with sharp edges.

Reliable processing

With TRUMPF you opt for reliable machines, a smooth production and high-quality results. The perfect combination of laser power, machine concept and intelligent functions lets you produce high-quality parts in little time using fusion and flame cuts – even with complicated applications, fine contours or thick sheet metals.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

![[Translate to th_TH:] TruLaser Serie 1000 Basic Edition](/filestorage/TRUMPF_Processed/_processed_/6/4/csm_TruLaser-1030-fiber-L99-Basic-Edition-product-picture_7807ad35f6_79fe998607.jpg)

![[Translate to th_TH:] TruLaser Serie 1000 Basic Edition](/filestorage/TRUMPF_Processed/_processed_/6/4/csm_TruLaser-1030-fiber-L99-Basic-Edition-product-picture_7807ad35f6_332f7c69a4.jpg)