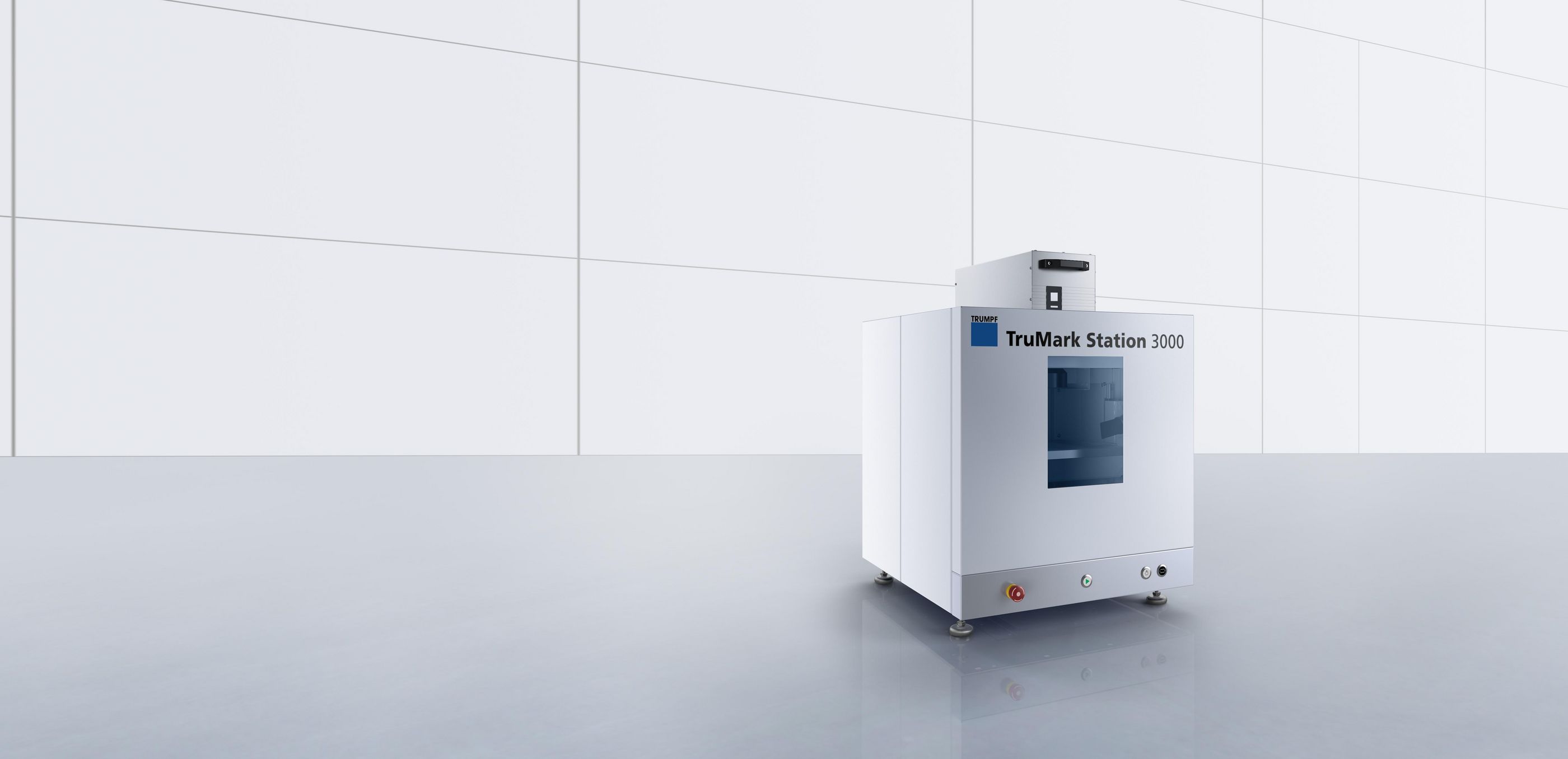

The TruMark Station 3000 expands the range of TRUMPF marking work stations with a new solution for a large variety of marking tasks and materials. The new work station is ideal for customers with small and medium lot sizes who want to integrate marking into their production, and are looking for a simple, safe, and robust industrial work station.

Compact and varied

The TruMark Station 3000 combines simplicity and convenient operation in a marking system for processing medium lot sizes. An optional rotary axis offers flexibility for marking various components. With exterior dimensions of only around 600 millimeters, the TruMark Station 3000 forms a compact marking cube, which provides a true desktop solution in combination with the TruMark 1110 or TruMark 5010 one-box lasers as well as the TruMark 6030.

The compact marking station is convenient and intuitive to operate and ideal for small and medium lot sizes.

You can combine the TruMark Station 3000 with all marking lasers in the TruMark Series 1000, 3000, 5000 and 6000

The safety-monitored laser protection door makes sure that your employees are safe.

Convenient and intuitive operation are just as important as ergonomics.

Annealing

Local heat input is used to discolor the workpiece surface. The annealing color changes depending on the material and the energy input. The surface stays smooth, which means that dirt cannot be deposited.

Engraving

During engraving, the laser beam removes part of the base material, thus creating a depression. This may have steep or beveled edges.

Discoloration

If the material and laser wavelength are optimally matched, the dye molecules in the material can be deliberately discolored or faded. The surface remains smooth.

Structured surfaces

The laser can be used to structure surfaces for a specific function. If the surface is structured with tiny melt elevations, significantly higher adhesion effects can be achieved with the same material properties. If interlocking components are structured after the addition of micro-depressions, the running characteristics improve significantly with the same quantity of lubricant.

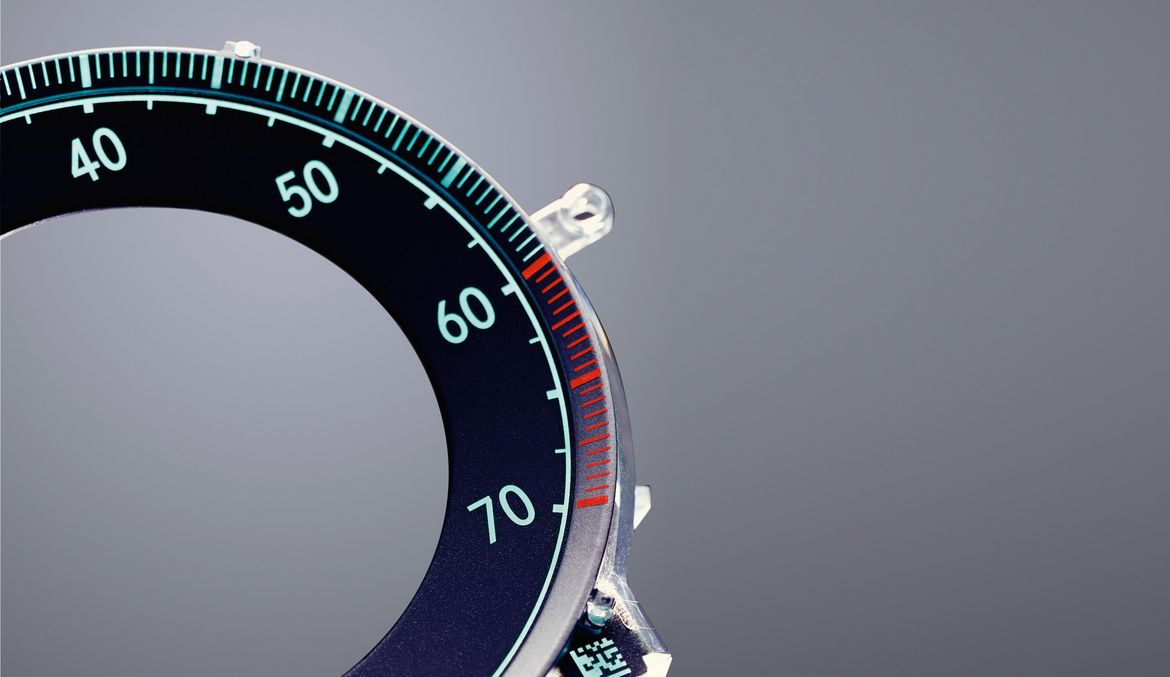

Ablation

Ablation partially removes thin top layers of multi-layer plastics which are applied to the basic material and have very different colors. This process can be used for the day and night design, for example, which is used in the automotive and other industries.

|

TruMark Station 3000

|

|

|---|---|

| Workpiece specification | |

| Maximum workpiece dimensions (W x H x D) | 440 mm x 200 mm x 350 mm |

| Maximum workpiece weight | 12 kg |

| Available motorized axis | |

| Traverse path of the Z axis | 200 mm |

| Z traverse speed | 2.4 m/min |

| Connection and consumption | |

| Electrical connection (voltage) | 100 V - 230 V |

| Electrical connection (frequency) | 50 Hz - 60 Hz |

| Dimensions and weight of work station | |

| Dimensions of work station (W x H x D) | 625 mm x 680 mm x 670 mm (without supply unit, without processing unit, without suction hose) |

| Laser class | |

| Laser class | 1 |

The technical data of all product versions as a download.

TruTops Mark 3D

Our TruTops Mark 3D marking software is ideal due to its user-friendly operation and significantly shorter process times. From now on, depending on the application, multiple objects to be marked can be reached with a laser system – especially where multiple lasers would have been required in the past. This makes the marking of three-dimensional surfaces such as sloping or curved surfaces very easy and efficient. In addition to the marking software, the package also includes a comprehensive 3D CAD editor, which can be used to independently create workpieces, and from which drawings for 3D marking can created.

The TruMark Station 3000 is perfectly tailored to the TruMark Series lasers and offers the right solution for any application.

The additional options for the TruMark Station 3000 optimize your production and improve user-friendliness.

A rotary axis with stepping motor enables laser marking of rotationally symmetrical components with a maximum weight of 2.5 kg, including hand-operated chuck with a diameter of 65 mm. You can use a TruMark Station 3000 that has been expanded with this option to produce high-quality circumference marking.

The pilot laser is used to simulate the marking content with a visible red light via a laser diode. This gives you an idea of the marking results in advance so you can position the component in the marking field even more easily.

The integrated exhaust system means that small particles and smoke emissions can be extracted during laser material processing. The system provides the option for remote activation.

In the event of a fault, TRUMPF service experts will remotely access your laser via a secure remote connection. In many cases faults can be remedied directly in this way, or the configuration of the laser can be modified in a way that permits you to continue manufacturing until the spare part arrives.

The external exhaust system enables small particles and smoke emissions to be extracted during laser material processing. There is the option of an extension hose (+ 10 ft. => total length max. 16 ft.). In addition, the system provides the option for remote activation. Depending on the application, you can choose from several models.

There are many focusing lenses available in different focal lengths for all wavelengths of the TruMark Series. You can select the optimum combination of wavelength and focal length for every application.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.