Optimal loading and unloading

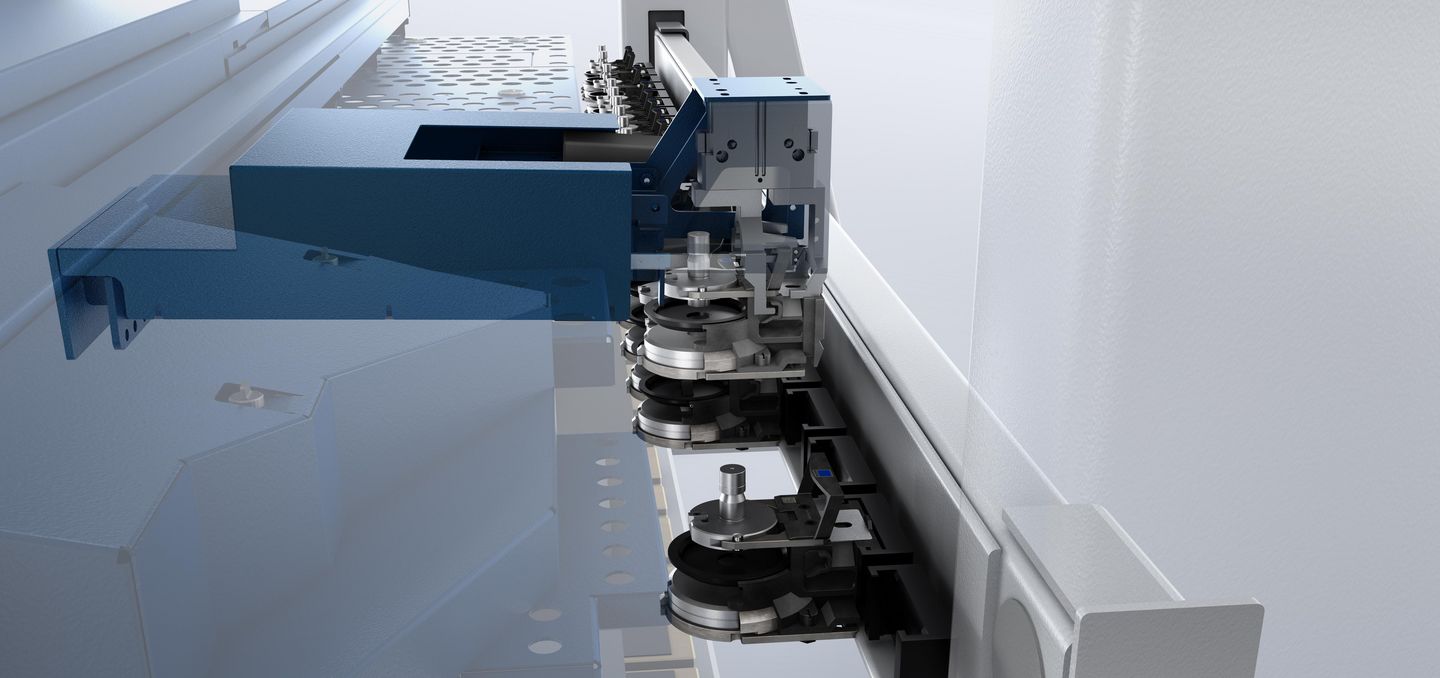

The SheetMaster loads and unloads your punching or punch laser machine and sorts parts reliably. Suction cups take sheets or blanks from the loading station and move them to the machine table. The SheetMaster deposits finished parts on an unloading platform. By using various suction cups, you can process an extensive variety of applications, depending on machine type.

Programmable suction areas guarantee safe handling of sheets up to 0.3 inches thick.

The SheetMaster also works reliably and fully automatically during shifts where there is little or no personnel.

Without any additional aids, the SheetMaster not only ensures the automated loading and unloading of sheets, single parts are also directly removed from the machine and sorted.

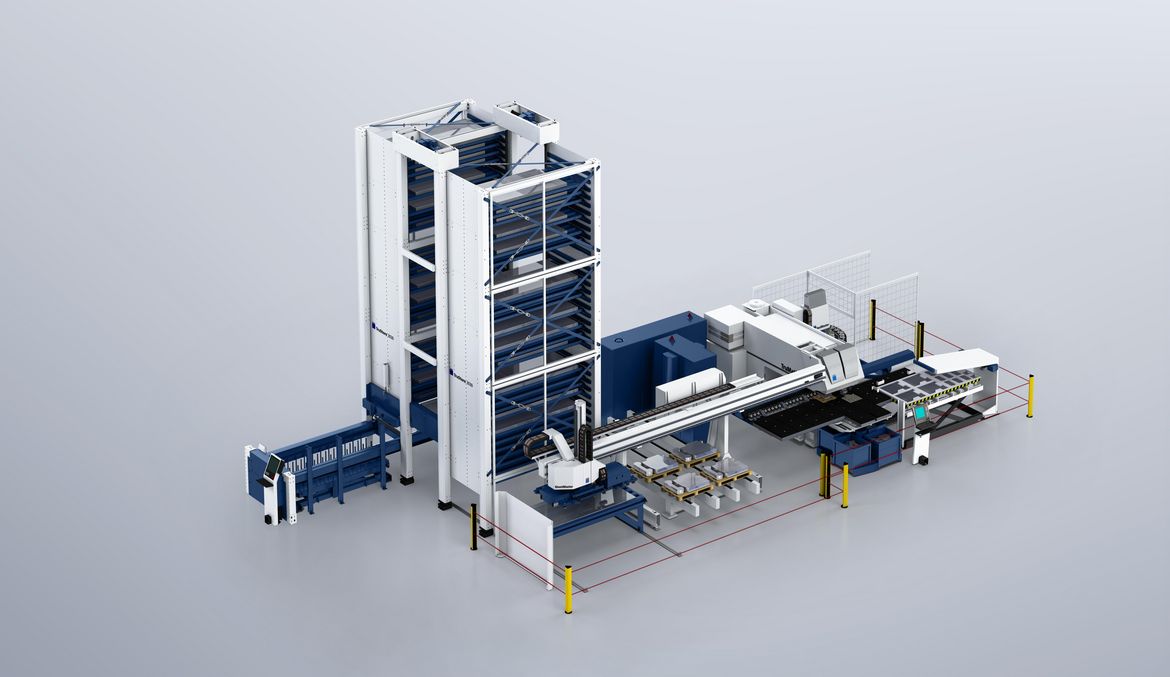

In combination with the TruStore, SortMaster Box and GripMaster, it is very easy to expand the SheetMaster into a processing cell.

|

Medium format for TruPunch 5000 (S12)

Compare product

|

Large format for TruPunch 5000 (S12)

Compare product

|

Oversize format for TruPunch 5000 (S12)

Compare product

|

Medium format for TruMatic 6000 (K05) / TruMatic 6000 fiber (K06)

Compare product

|

Large format for TruMatic 6000 (K05) / TruMatic 6000 fiber (K06)

Compare product

|

Oversize format for TruMatic 6000 (K05) / TruMatic 6000 fiber (K06)

Compare product

|

Medium format for TruMatic 7000

Compare product

|

Large format for TruMatic 7000

Compare product

|

Oversize format for TruMatic 7000

Compare product

|

|

|---|---|---|---|---|---|---|---|---|---|

| Loading | |||||||||

| Maximum sheet size | 2500 mm x 1250 mm | 3000 mm x 1500 mm | 4000 mm x 1500 mm | 2500 mm x 1250 mm | 3000 mm x 1500 mm | 4000 mm x 1500 mm | 2500 mm x 1250 mm | 3000 mm x 1500 mm | 4000 mm x 1500 mm |

| Minimum sheet size | 600 mm x 370 mm | 600 mm x 370 mm | 600 mm x 370 mm | 600 mm x 370 mm | 600 mm x 370 mm | 600 mm x 370 mm | 650 mm x 560 mm | 650 mm x 560 mm | 650 mm x 560 mm |

| Unloading | |||||||||

| Minimum part size | 170 mm x 170 mm | 170 mm x 170 mm | 170 mm x 170 mm | - | - | - | - | - | - |

|

Medium format for TruPunch 5000 (S12)

|

Large format for TruPunch 5000 (S12)

|

Oversize format for TruPunch 5000 (S12)

|

Medium format for TruMatic 6000 (K05) / TruMatic 6000 fiber (K06)

|

Large format for TruMatic 6000 (K05) / TruMatic 6000 fiber (K06)

|

Oversize format for TruMatic 6000 (K05) / TruMatic 6000 fiber (K06)

|

Medium format for TruMatic 7000

|

Large format for TruMatic 7000

|

Oversize format for TruMatic 7000

|

|

|---|---|---|---|---|---|---|---|---|---|

| Loading | |||||||||

| Maximum sheet size | 2500 mm x 1250 mm | 3000 mm x 1500 mm | 4000 mm x 1500 mm | 2500 mm x 1250 mm | 3000 mm x 1500 mm | 4000 mm x 1500 mm | 2500 mm x 1250 mm | 3000 mm x 1500 mm | 4000 mm x 1500 mm |

| Minimum sheet size | 600 mm x 370 mm | 600 mm x 370 mm | 600 mm x 370 mm | 600 mm x 370 mm | 600 mm x 370 mm | 600 mm x 370 mm | 650 mm x 560 mm | 650 mm x 560 mm | 650 mm x 560 mm |

| Unloading | |||||||||

| Minimum part size | 170 mm x 170 mm | 170 mm x 170 mm | 170 mm x 170 mm | - | - | - | - | - | - |

The technical data of all product versions as a download.

To ensure the fastest possible supply of materials, you can connect your machine to your materials store. In this context, you can expand your SheetMaster with TRUMPF cart systems in accordance with your individual needs. Raw sheets are automatically provided where they are needed.

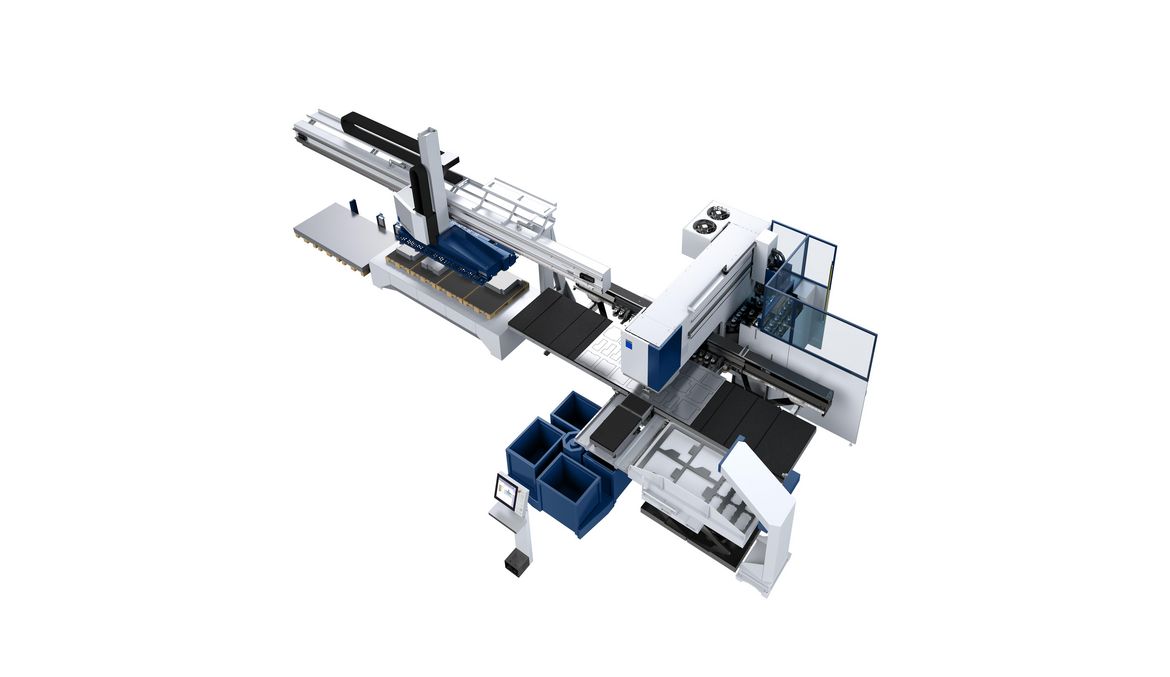

With the SortMaster Pallet, you can sort parts removed from the SheetMaster onto up to 6 different europallets in a longitudinal or transverse arrangement in a fully automated fashion. You thereby increase unloading capacity and markedly increase the overall productivity of your system.

You can use the cart systems with belt drives either for loading and unloading the SheetMaster, or use them to connect a storage system.

When connecting the SheetMaster to the TruPunch 3000, TruMatic 6000, and TruMatic 6000 fiber, you have the capability of increasing your tool capacity with the "integrated tool changer" and thereby save on space.

Programmable suction areas make removal of delicate and large parts possible. The pivoting function of the suction cups also guarantees the loading of small blanks with process reliability.

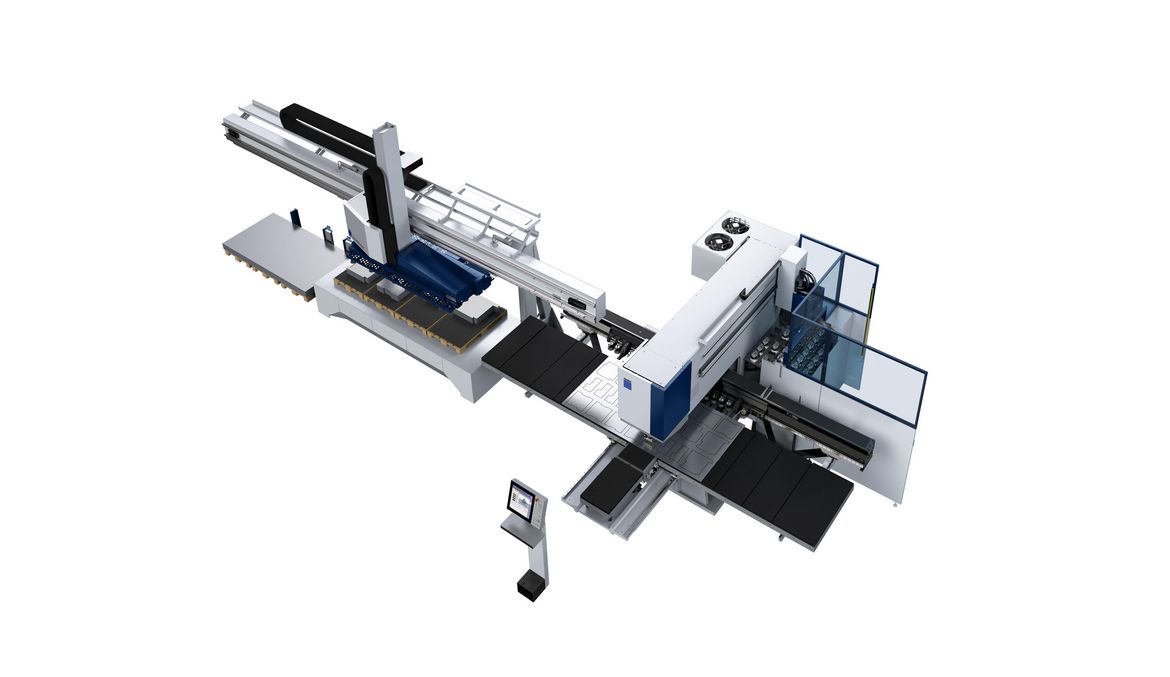

With the SheetMaster, you substantially increase your productivity. When manufacturing medium to large lot sizes, the automation component loads and unloads sheets with process reliability, parallel to production.

TruMatic 6000 fiber with SheetMaster and GripMaster

TruPunch 3000 with SheetMaster, SortMaster Box Linear, and DisposeMaster

TruMatic 7000 with TruStore 3030 and SheetMaster, dual loading carts on tracks, SortMaster Pallet, SortMaster Box, GripMaster, and ToolMaster

TruPunch 5000 with SheetMaster, SortMaster Box, GripMaster, and ToolMaster Linear

TruPunch 5000 with SheetMaster and ToolMaster Linear

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.