Andrea Zampar has a passion for large projects. No matter whether it involves parts for elegant skyscrapers, interiors for a cruise ship, or metal housings for thousands of ticket stations in the Paris Métro — the CEO at Metalinox, located in northern Italy, enjoys thinking and acting at large scale. This is a strategy that helps get him through difficult times. “In Italy we are in an uncertain period right now. That is why we have significantly boosted our share of large orders going to the rest of Europe and overseas, and will continue to do this. We are aiming for 75 percent,” says Zampar.

This approach provides a degree of certainty, but it also requires major effort on the part of his firm. “To make a valuable contribution to a major project, we have to satisfy two prerequisites. First, we must always be willing to accept new challenges. The second is that we have suitable technologies and the qualified staff needed to turn out excellent products. Metalinox has achieved both.”

Extraordinary skyscraper

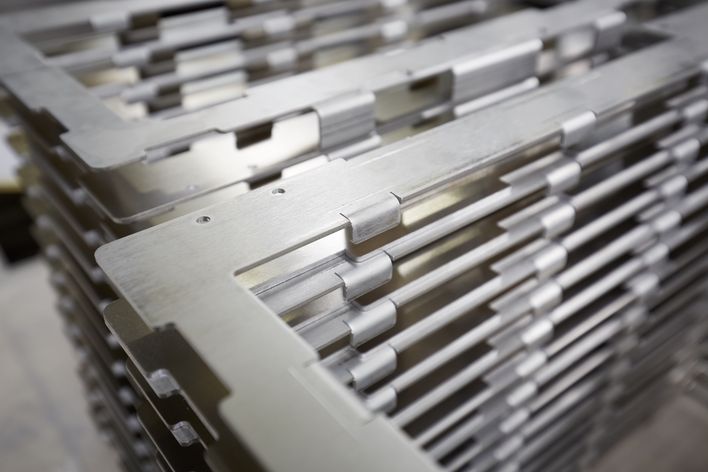

Recently his company demonstrated these abilities when taking part in the construction of the Tour Odéon in Monte Carlo. This striking skyscraper, 170 meters tall and with 50 floors, will be opening at the end of the year and is the tallest building in the Principality of Monaco. Zampar proudly describes the part that Metalinox had in erecting this structure. “Every single stainless steel part on the building’s façade and on the balconies came from our shop. Here we had to hold sway against tough competition from all of Europe. We were able to do that particularly because we could show high-quality prototypes in short order.” In more concrete terms, Metalinox manufactured the 2,400 curved handrails with retainers for the panes of glass on the balconies. When making up the facing for the tower, the Italian company used the laser to weld 288.6 kilometers of seams.

Traditionally TRUMPF

To finish such high-volume orders in superb quality and within a tight time schedule, Zampar places his faith in more than two dozen TRUMPF machines. “Our cooperation with this mechanical engineering company began in 1994, with the legendary TRUMATIC 200 R punching machine. Since that time we have invested in 41 further TRUMPF machines. Now if you’re thinking that I’m thoroughly satisfied with the quality of these products, then you’re absolutely right,” he explains with a laugh. Today the Metalinox production building houses four punching machines, two punch laser machines, a tube cutting machine, 15 press brakes, three 2D laser cutting machines, a bending robot and a variety of welding robots. The machinery is augmented by manual welding stations and mechanical sheet metal processing.

Metalinox s.r.l.

headquartered in Fiumicello, Italy.

Founded in 1981, 100 employees.

<link http: www.metalinox.it>www.metalinox.it

Collaboration on large projects around the world and supplier to the food, furniture and aviation industries.

Four punching machines, two punch laser machines, a tube cutting machine, 15 press brakes, three 2D laser cutting machines, two 3D laser cutting and welding machines, a bending robot and several welding robots.

This makes it possible for Metalinox to work a wide variety of materials — from stainless steel to copper and brass, and on to aluminum and iron. The lots range from one-off items to mass production. Whatever the customer wants, he gets. “Impressive performance has been rendered consistently by the TruLaser 3030, in particular,” says Zampar. To an ever increasing extent, automation is playing an important role. “The correlation between investments in automation and production volume is almost linear.”

No worries about new staff

At the same time the manager is fully aware of his company’s second major plus. “My employees, about one hundred in number, are an extremely important factor in our success. Especially in large-scale projects, they have to be extremely creative, all the way from the planning stage to final production and assembly. They have to be able to work as a team.” Moreover, good language skills, unwavering commitment, and great flexibility are needed for foreign projects.

Zampar has no difficulty finding new talent. “This region always turns out promising young people who want to work for our company.” This is a trend that Zampar promotes by cooperating with schools nearby, to make those young talents familiar with his company as early as possible. That is one reason why the CEO has a bright outlook. “The future is always uncertain and requires a high degree of flexibility. But we will continue to dare to undertake new ideas and continue to be the pioneers that we have been for the past 31 years.”

This article was first published in autumn 2014.