Safety awareness starts in development

Safety is incorporated into every automation solution right from the concept phase. This is based on the EN ISO 12100 standard, which requires a comprehensive risk assessment across all life phases. TRUMPF relies on interdisciplinary teams that identify mechanical, electrical, thermal and ergonomic risks – initially in theory, and later also on real prototypes. This creates an inherently secure system that satisfies all legal requirements.

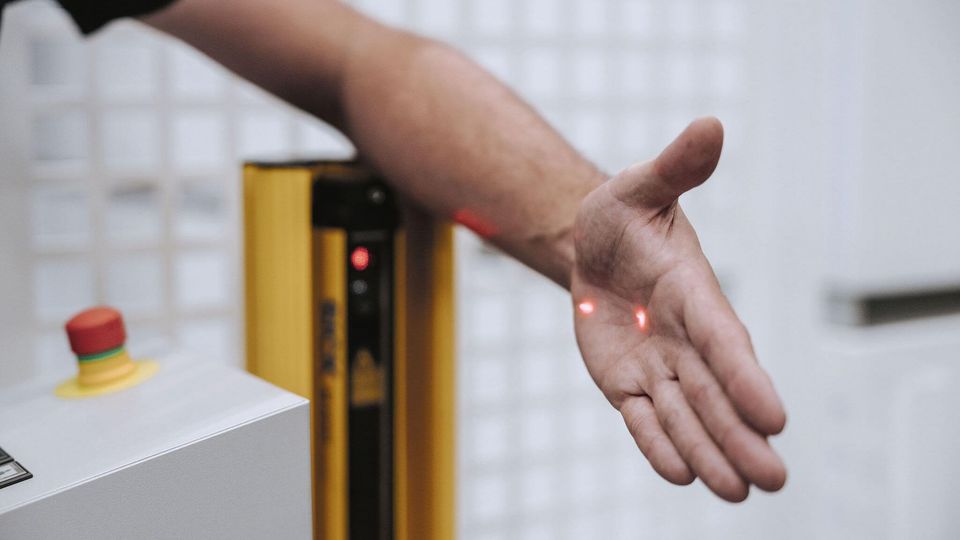

Technology provides focused protection

From safety light barriers at loading zones to laser scanners for room monitoring, modern protection systems ensure safety exactly where it matters. Example: The SheetMaster with the parallel to production option (for loading and unloading) uses a laser scanner to monitor the area around the finished parts stack. What makes this unique is that production continues uninterrupted on the basic machine while operators are already removing and inspecting parts. This has the advantage that protective mechanisms only intervene in emergencies, while the automated process remains efficient and secure.

Less noise, more protection

Sheet metal production can be noisy at times – especially when large, fully automated machines are in operation. That is why TRUMPF relies on technologies that protect employees' hearing in its automation solutions. For example, the SortMaster Station has a special sound-proof cabin. This reduces the noise generated when separating the workpieces from the scrap skeleton, which helps to increase personnel concentration levels.

Customised safety for every application

TRUMPF tailors the safety concept of its automation solution optimally to the machine environment at the user's site. This allows TRUMPF experts to increase efficiency in a targeted manner while ensuring a high level of safety – without compromising productivity. From LiftMaster and SheetMaster to external robot connections, our risk-assessed safety solution ensures reliable processes and gives operating personnel the security they need in their daily work.

Modern protection systems ensure safety exactly where it matters. For example, an entire network of invisible safety light barriers ensures that TRUMPF machines only run when no one is located in the safety areas.

Practical tests instead of theory

In the TRUMPF test area, experts examine all safety-related functions of automated solutions under real-life conditions. Noise measurements, long-term tests and site inspections with service teams are carried out to ensure that concepts work in practice as well as on paper.

Increased efficiency through separate zones

Modular safety concepts enable parallel operations – employees can enter certain areas while the machine continues to process parts in other areas. The clear separation of loading and unloading zones provides greater flexibility, without compromising on safety. This delivers efficiency benefits, particularly in interlinked, automated systems, as the system remains productive throughout.

Well-designed software for safe operation

Many automation units are controlled directly via the machine panel – centrally, clearly and without additional displays. All safety-related information and functions are grouped together there so that the operator can maintain an overview at all times. The system requires deliberate acknowledgement at the start post for safety-critical actions – by pressing a button and activating the foot switch. At the same time, it automatically checks whether protective measures are in place, such as a closed fence. This is how TRUMPF reliably prevents unsafe conditions – and significantly increases operator safety in everyday use.

Safety doesn't end with delivery

TRUMPF supports its customers during the commissioning of their machines. A comprehensive safety concept plays a crucial role, particularly in automated processes where humans and machines work closely together. This is the only way to reliably minimise risks and ensure smooth operation. As part of the safety equipment inspection process, trained TRUMPF service engineers check all of the system's relevant safety functions on site at the customer's premises, conduct training courses and instruct personnel. These services are supplemented by training courses at the company's headquarters in Ditzingen, training videos on safety, and detailed operator's manuals and service manuals – including all documented hazards.

Field experiences provide valuable insights

TRUMPF draws on real-world experience when developing its practical applications, as insights from customer projects and feedback from the service department flow directly into the further development of automation solutions. Particularly when it comes to safety-related interfaces between machines and automation, users benefit from tried-and-tested, continuously optimised concepts – for enhanced safety in real-world operation.