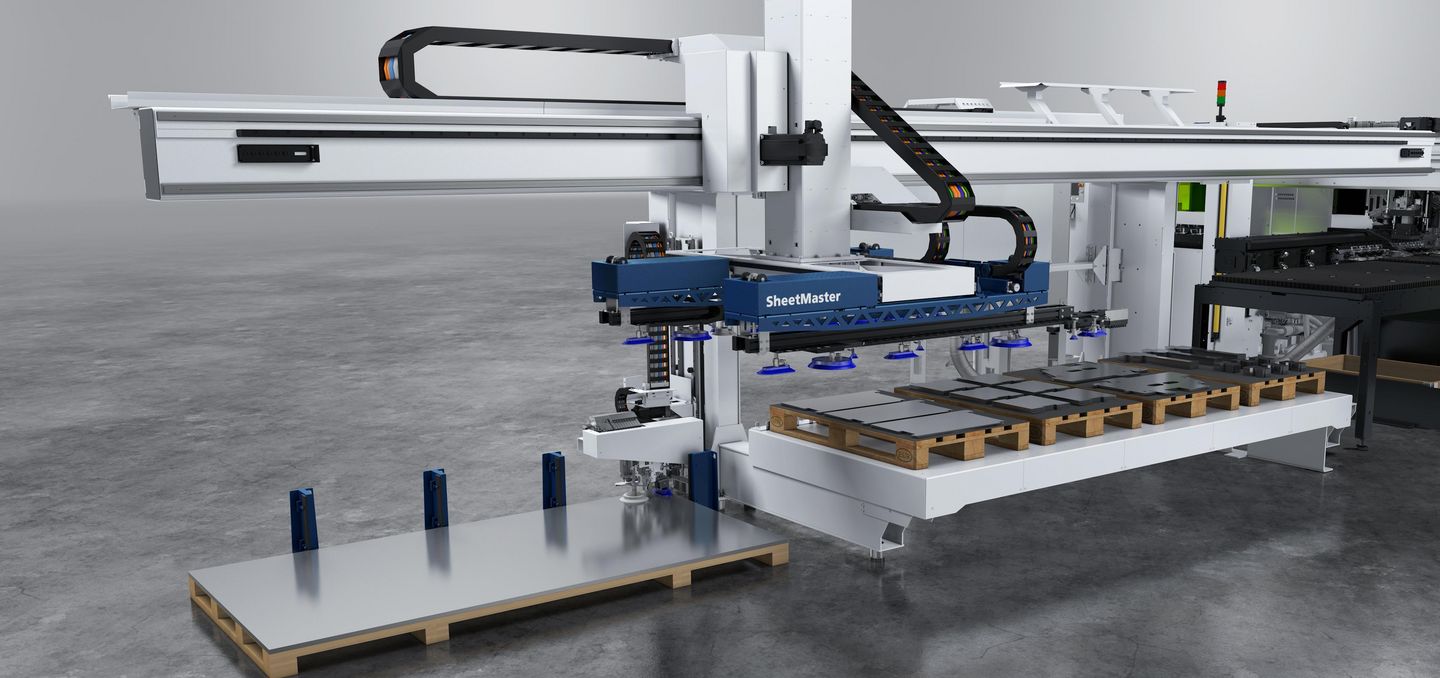

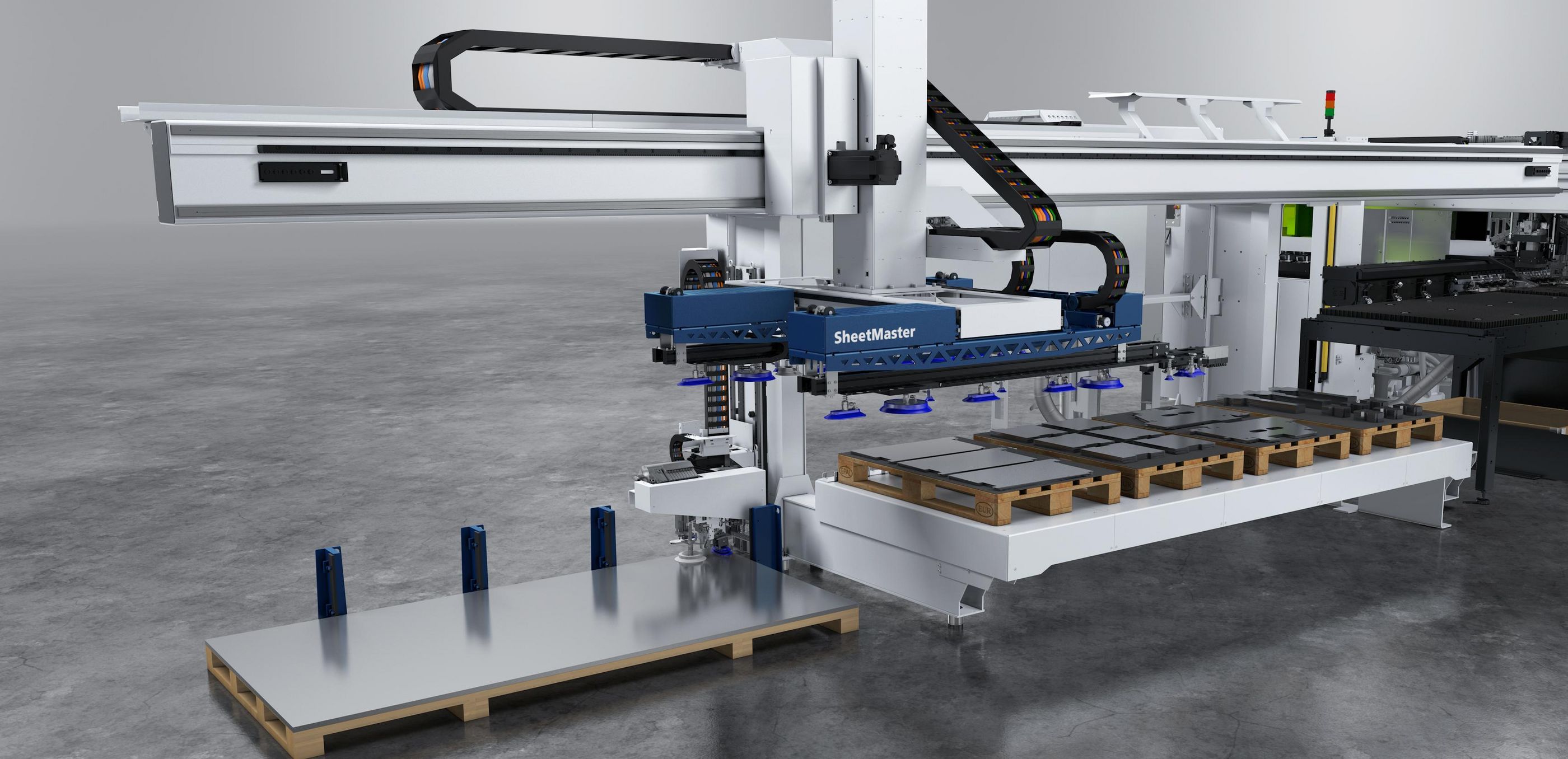

Optimum loading and unloading, palletizing and sorting

The new SheetMaster reliably performs automated loading and unloading of your punching machine or punch laser machine. It also sorts and palletizes your finished parts. The separating station ensures even faster loading, as raw sheets are pre-separated while the SheetMaster is still unloading parts. Individually selectable suction cups simplify the removal process. The SheetMaster's additional sorting axis sets your finished parts down flexibly in the most space-saving way. You can expand and connect your SheetMaster with additional components.

The SheetMaster can easily remove sheets up to 6.4 mm, or up to 8 mm with the additional suction cup package, which increases the load capacity to 300 kg.

The SheetMaster removes heavy and small parts quickly and safely. It flexibly handles palletizing and de-stacking between stacks.

The SheetMaster also works reliably and fully automatically during shifts where there is little or no personnel.

The GripMaster disposes of scrap skeletons, remainder strips and microjoint sheets fully automatically.

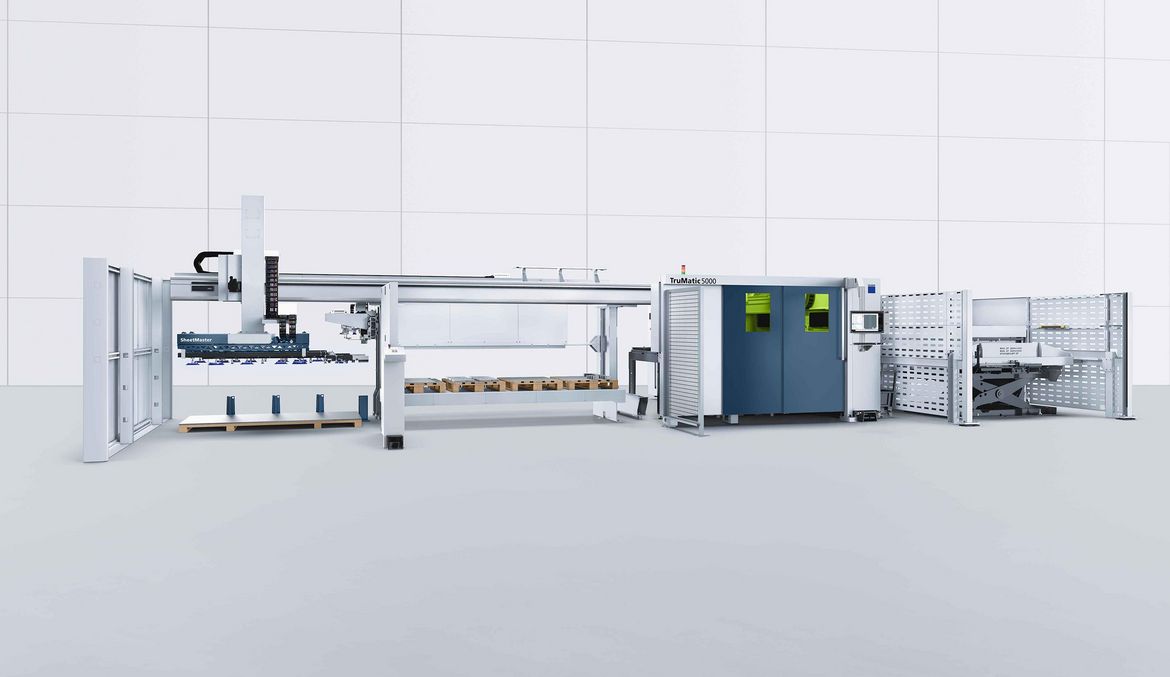

Expand the SheetMaster with TruStore storage, STOPA store and various cart systems.

The simultaneous pre-separation of raw sheets and depositing of finished parts ensures speed.

With the SheetMaster, you increase your productivity considerably. When manufacturing medium to large lot sizes, the automation component loads and unloads sheets with process reliability, parallel to production.

The gripping unit consists of a gripper bar and gripper arms with individually controllable suction cups. It can palletize parts in any order and create intermediate stacks. The additional Y axis allows it to fully utilize the stacking area.

The separating station separates raw sheets quickly and reliably while the SheetMaster is still unloading parts. This shortens the loading operation.

TruMatic 5000 with SheetMaster (New Generation)

The ultra-productive punch laser production cell manufactures your parts fully automatically, with high energy efficiency and optimum part quality.

TruMatic 5000 with SheetMaster (New Generation)

The ultra-productive punch laser production cell

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.