Series production would not work without specialists like Daniel Weller and his colleagues at ElringKlinger AG. They develop and test all production processes on a pre-series machine before transferring them to the production lines at one of ElringKlinger's 40 sites worldwide, ensuring that they are defect-free and fully reproducible. Their work is essential, but expensive. Each day of development work costs money that is only recouped when series production starts. Weller and his team have to keep the ramp-up phase for the production lines as brief as possible, so they are always keen to embrace any tool that speeds up development. Weller listened intently when he first learned about EasyModel AI during a visit to TRUMPF's Laser Application Centre.

"The AI-based programming wizard was still in its final development stage back then, but it was clear that it could be of interest to us," recalls Weller, a specialist in joining technology in ElringKlinger's Battery Technology division. As it sometimes happens, ElringKlinger received an order for series production of an innovative cell contacting system soon afterwards, presenting an ideal opportunity to put EasyModel AI to use.

Smart solution for complex requirements

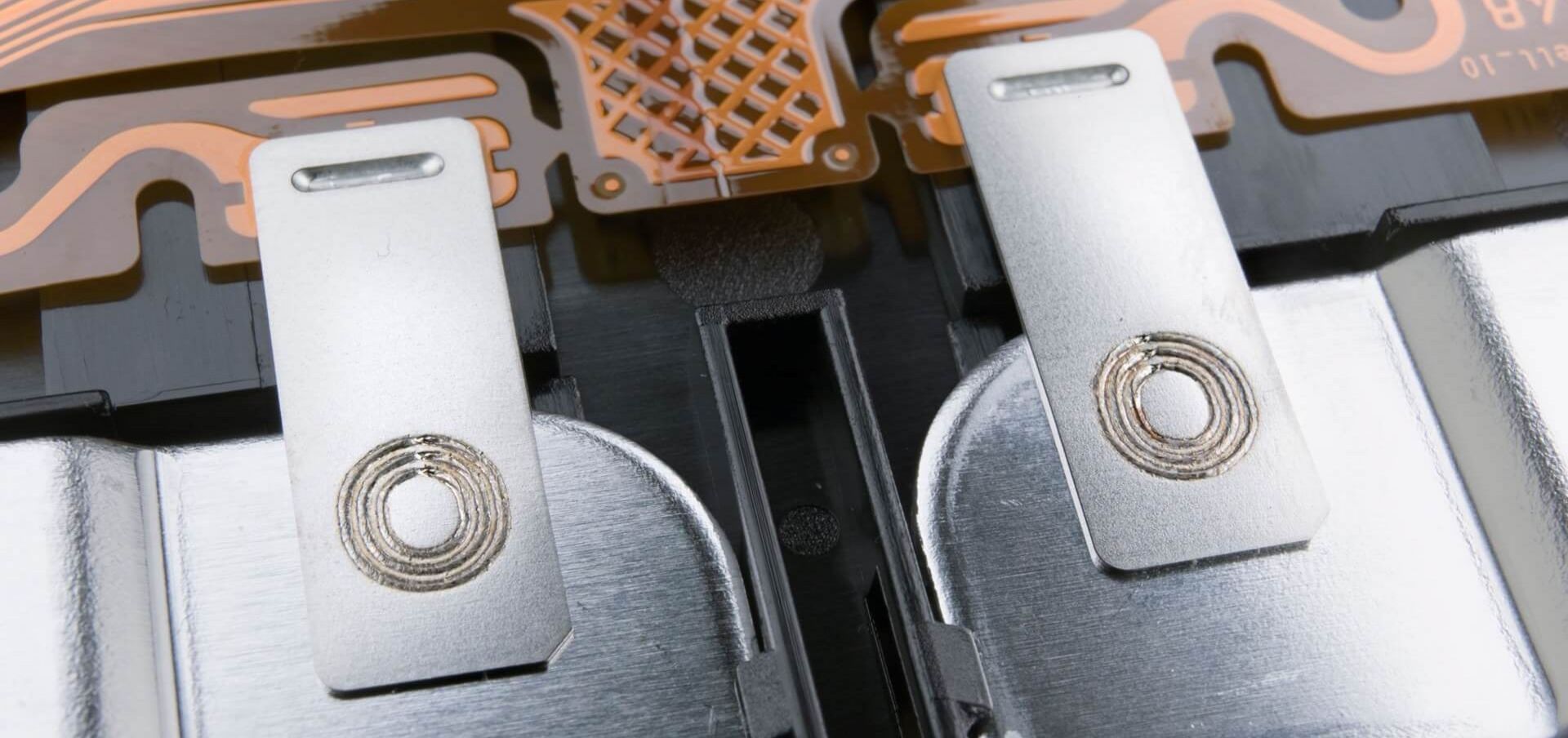

ElringKlinger AG is an independent global supplier to the automotive industry. The company supplies innovative solutions for all drive types – for both passenger cars and commercial vehicles. For example, ElringKlinger has been manufacturing cell contacting systems (CCS) for electric drives for many years. This crucial component for e-vehicle battery packs connects the individual battery cells to form a single unit, facilitating the transfer of electrical power from the battery to the consumer. The CCS also transmits measuring data on voltage status and temperature to the battery management system via strip conductors. The zero-defect strategy applies to series production of this vital component. Until now, module-to-pack battery designs have generally been the standard. In this approach, battery cells are first assembled into modules and then integrated into a battery housing. The CCS required for this process are approximately 600 millimetres long and feature between 10 and 20 weld point positions, which the laser must accurately detect and join during series production.

"The requirements have since evolved," Weller explains. "In the next generation of vehicles, cell-to-chassis designs will be implemented, where battery cells are placed directly into the battery housing instead of being grouped into separate modules. The battery is no longer a separate part attached to the automobile body, but is integrated into the body itself to form the vehicle's underbody. This design saves space and weight, increases energy density and simplifies the design. However, it demands much more precise component manufacturing. Here, CCS components with around 50 weld point are used; these products are nearly two metres long but only 20 millimetres thick. "Developing a stable and efficient series production process with short cycle times is no man feat," says Weller.

Simple, standardised detection

Previously, ElringKlinger AG used TRUMPF VisionLine Detect image processing with position-dependent exposure settings. By varying the exposure settings, individual positions could be detected. However, this process had to be performed separately for each position within the processing field to compensate for position-dependent reflections on the part surface. This time-consuming, iterative process depended on many factors and had to be customized for every part position. “Thanks to the models generated by EasyModel AI and the resulting filters, this labour-intensive manual customisation has become a straightforward standard procedure,” says Weller.

Achieve optimal results without any programming knowledge

EasyModel AIis a zero-code programming wizard that allows users without programming knowledge to create and train customised, image-based AI models. "As before, we use VisionLine Detect to take image recordings of the part areas containing weld points. We drag and drop them into the EasyModel AI tool, which can be accessed on MyTRUMPF," explains Weller. After creating a project, he and his colleagues use a marking tool to mark the welding points to be detected on the images. This process works much like drawing on a tablet. The AI then analyses the data and generates a model that Weller and his colleagues can gradually optimise.

"A few training images are enough to create a functional AI model," says Weller. "Once we are satisfied with how the model is working, we integrate it into the production line and test it on our actual parts." This is where the new AI filter option for VisionLine Detect comes into its own. This filter enhances VisionLine Detect's feature detection by more accurately distinguishing between relevant image areas and elements like fixtures, dirt or reflections. "The difference between VisionLine Detect with and without an AI filter is especially clear here," emphasises Weller. "The AI filter creates a binary image of the part, i.e. in black and white only. The detected part is displayed in white, with the surrounding areas in black. This allows the edge detection algorithms to easily identify the welding area to be detected."

AI speeds up process development

"Integrating EasyModel AI and the AI filter into VisionLine Detect only required activation of the option," reports Weller. During commissioning of the pre-series system, TRUMPF experts guided Weller and his colleagues through the EasyModel AI process steps. "We achieved our first result within just a couple of hours", says Weller. This ease of use is a clear advantage for Weller. "Even once series production is underway, adjustments will occasionally be needed. That's when colleagues at our various locations need to get involved," he explains. "So it's great that the system operates on a 'what-you-see-is-what-you-get' basis. This makes it easy to understand, even for those without programming experience."

In pre-series development, the focus is on saving time. "EasyModel AI picks up the pace here. We need hours rather than days to achieve good results, and retraining also saves a great deal of time", says Weller. And because the EasyModel AI, AI filter and VisionLine Detect technology trio is so user-friendly, Weller is increasingly using it for small series and prototyping as well. "That was previously too time-consuming," he explains. Weller and his colleagues are now keeping a close watch to identify other areas within the company where the new solution can be applied. "I see great potential wherever we need to detect large numbers of weld points with tight tolerances. AI just makes it quicker."