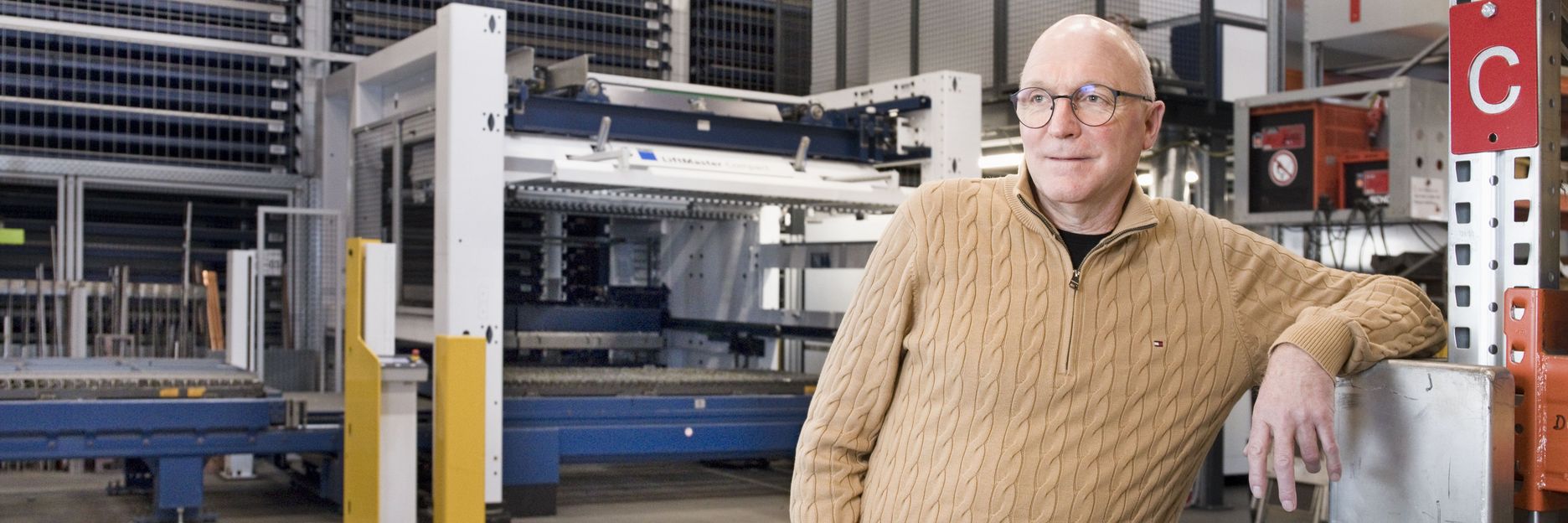

Krämer Brennteile is a traditional custom manufacturer with around 40 employees based in Hofstetten in the Black Forest. The company manufactures to order – from intricate formed parts to 50-millimetre thick gear plates. Series production is uncommon; instead, the company handles numerous small, often urgent orders that are produced alongside regular work. "We are fast, reliable and flexible – that's our trademark," explains managing director Martin Krämer.

More power, more possibilities

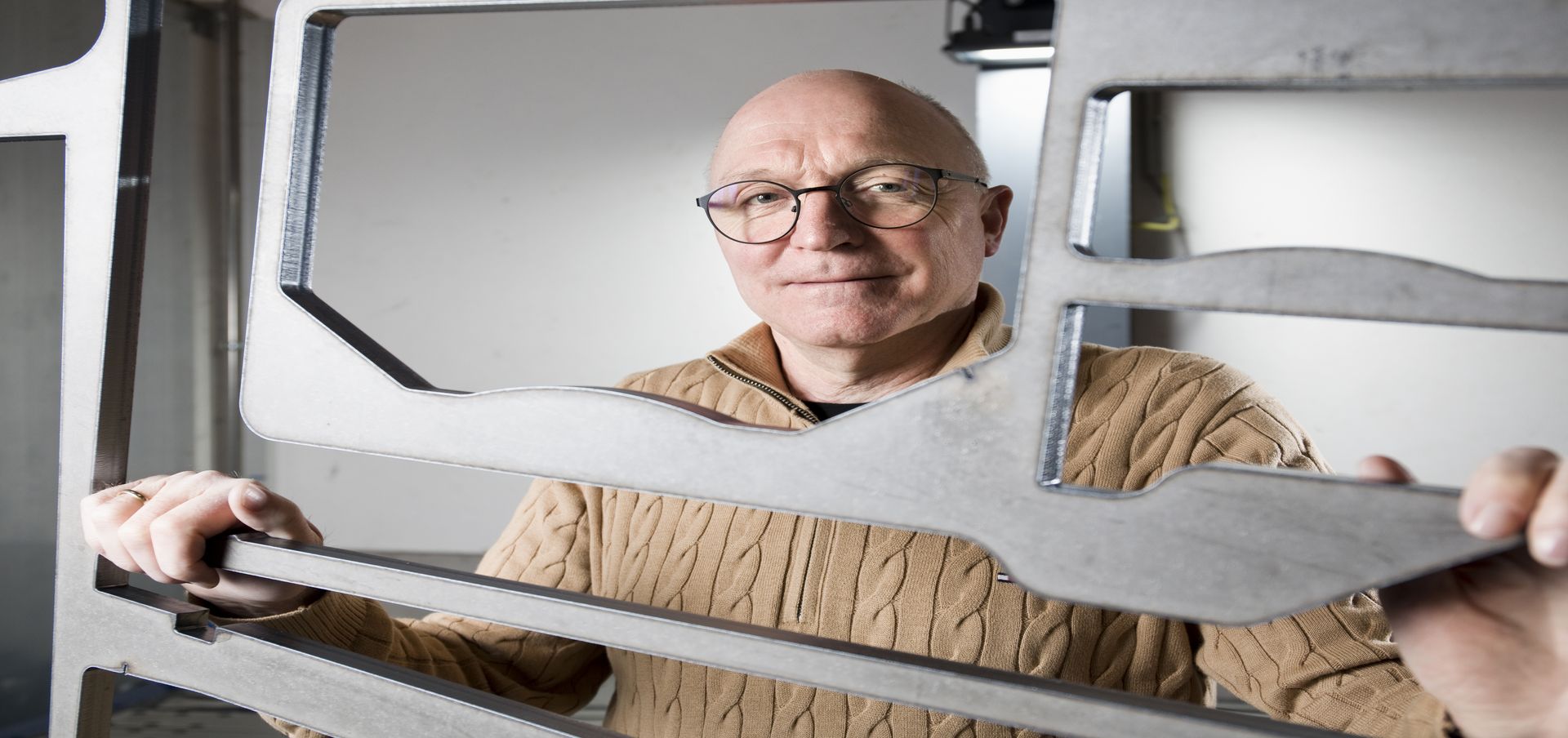

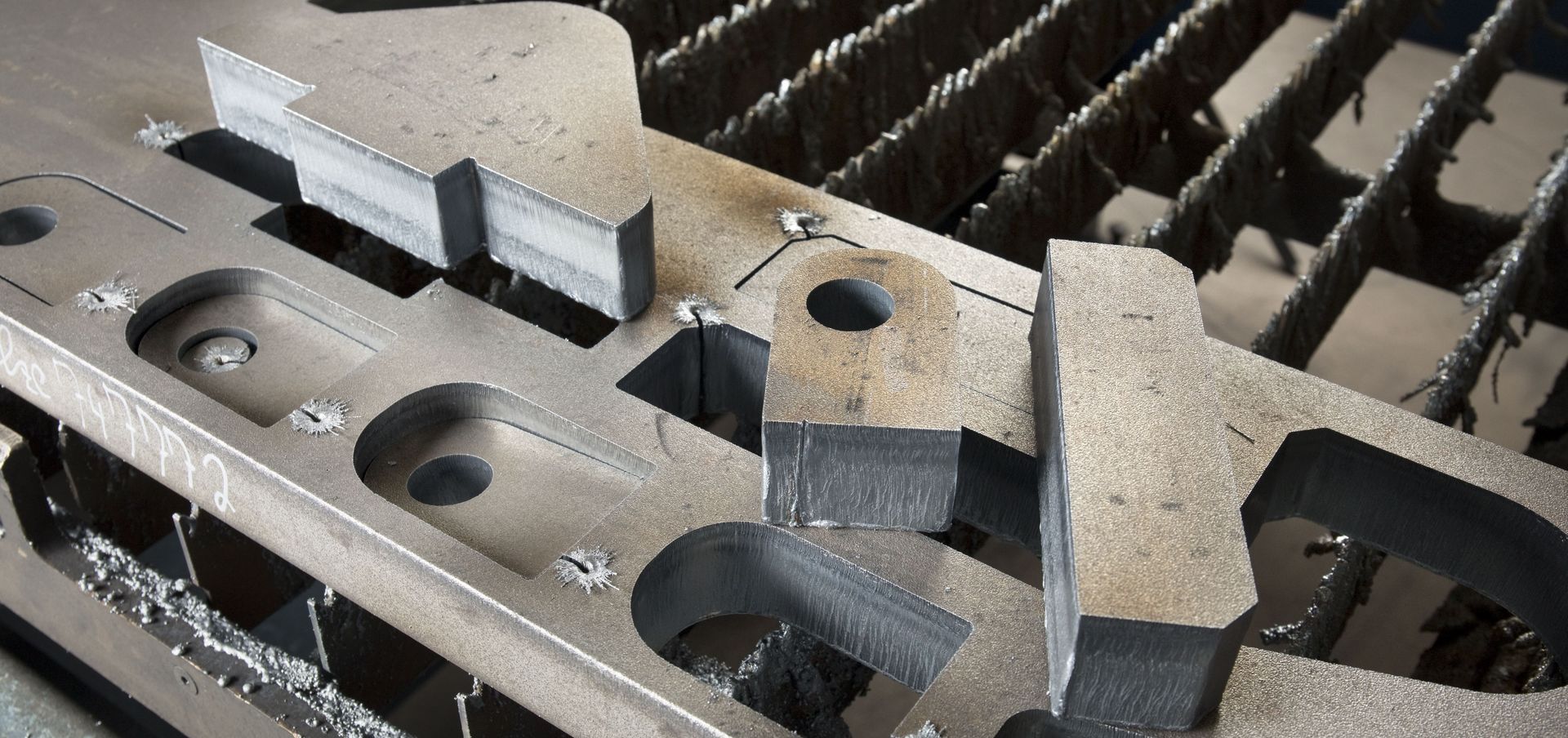

"We have made a name for ourselves with flame cutting," Krämer says . But he also knows that powerful laser systems are are a match for flame cutting when it comes to cutting thick material, and recognises the potential for his company. He is considering the TruLaser 5030 fibre laser cutting systemfrom TRUMPF, featuring an impressive 24 kW of laser power. "We have customers who need components with threaded holes up to 50 millimetres thick. Once flame cutting was complete, we used to have to mill these parts, which was a laborious process. With the 24 kW machine, we can do it with one tool setup," he says. His aim is to expand the range of services he offers so he contacts Felix Kuster, regional sales manager at TRUMPF.

Consulting with vision

When Kuster again brings up the topic of automation during a discussion about the machine, Krämer is sceptical, as he had been on earlier visits. "I was convinced it wouldn't work for us – too inflexible, too costly." Like many, he felt automation was only viable for large series. Apart from the space issue, he fears that automated processes will make it harder to work flexibly. "You can't just slip in a small order at short notice, as we have always done in the past," he says. But this time, Kuster is more persistent, explaining that the high productivity of the 24 kW laser will further speed up loading and unloading – and thus put pressure on existing processes. Krämer's employees are already reaching their limits when it comes to handling the heavy sheets.

Kuster suggests consulting Markus Semrau, Technical Sales Manager Smart Factory at TRUMPF, and Krämer agrees. Semrau uses the Smart Factory concept to analyse the entire process chain at Krämer – from material flow to part removal. It quickly becomes apparent that excessive forklift traffic, narrow paths and frequent manual reconfigurations are slowing down processes. Semrau demonstrates that the higher machine performance of the 24 kW system will further enhance this.

"The machine’s productivity only reaches its full potential when the surrounding environment is properly organised. Especially when space is limited, orderly processes and clear material flows are crucial," he summarises. Using figures, simulations and practical examples, he shows how automation can reduce throughput times, enable night shifts and stabilise material flow. Krämer's skepticism begins to wane.

An additional pallet for special orders

The TRUMPF experts bring about the decisive change by recommending a third pallet station for the laser system. This extension behind the machine is an additional loading and unloading station – in technical terms, a manually loadable buffer station that can be used independently of the automated storage system. Here's how it works in practice: while the first two pallets are loaded or unloaded, the third pallet moves into the machine and the order is cut. The additional pallet is loaded and unloaded manually or with the aid of a crane. This means that urgent special orders or particularly thick sheets of up to 50 millimetres can literally be "slotted in" without disrupting the automated production flow.

"The third pallet is a a real breakthrough," says Semrau. "It combines the speed of an automated system with the accessibility of a stand-alone machine." This also convinces Krämer – just ten weeks after the consultation, he decides to purchase the automation package.

More speed, more peace of mind, more safety

The TruLaser 5030 Fiber with 24 kW of power is equipped with a LiftMaster Compact loading and unloading unit and connected to a STOPA storage system. Material logistics operates digitally and largely unattended. Integrated inventory management ensures that the required sheet metal is available at the right time. There is no need to search for materials, and forklift traffic is minimised. This brings calm to production and increases occupational safety, with no suspended loads and more ergonomic handling of large sheets.

The system has been running in automatic mode since start-up. The difference is clearly noticeable, with clearly structured processes, less hectic activity and more relaxed working conditions. "In the past, employees had to clear the table as quickly as possible before the machine could continue working. Now it runs automatically and eases the pressure on our processes," says Krämer. The move has also paid off financially for him. Two operators on each shift can now focus on other tasks, productivity has increased and customers are delighted with the expansion of Krämer's product range.

Smart Factory on a small scale

For TRUMPF, the project is a prime example of how smart factory solutions can work well in smaller companies. "Automation doesn’t mean you have to remodel an entire production hall," says Semrau. "It is often sufficient to intelligently link existing processes." Krämer demonstrates that digitalisation and automation belong together. The company has been paperless for many years, and production is digitally controlled. The new system integrates seamlessly into this structure – and opens up new perspectives.

There is space on the company premises for another hall section, and the system is already designed to be mirrored. "I've done a lot in recent years," he says. "My daughter will soon take over the business, and she should have the opportunity to develop it further." The automation sceptic has become a staunch advocate. As he himself says, "You just have to experience it – then you understand what automation really brings."