Compact, light and versatile – the TruMicro Series 2000

Whether for structuring, ablating, cutting, or drilling: the laser has become an essential tool in micro-production technology. The fibre-based ultrashort pulse lasers in the TruMicro Series 2000 are distinguished by their compact and light design. Laser integration is made significantly easier by using a laser light cable for ultrashort pulse lasers (LLK-U).

With moderate average power and versatile adjustable parameters, they are perfect for applications such as cutting films, as well as precise structuring and marking.

The laser light cable for ultrashort pulse lasers (LLK-U) facilitates machine integration without free-beam guidance.

Operate the TruMicro 2000 with different repetition rates, pulse energies and pulse trains.

Advanced Pulse on Demand makes it possible to trigger laser pulses with trigger signals of varying frequency.

The TruMicro Series 2000 makes it possible to use cold processing for a large number of microprocessing applications.

Make use of the strengths of the laser for corrosion-free black marking on metals.

High beam quality enables cutting, welding and marking of transparent materials

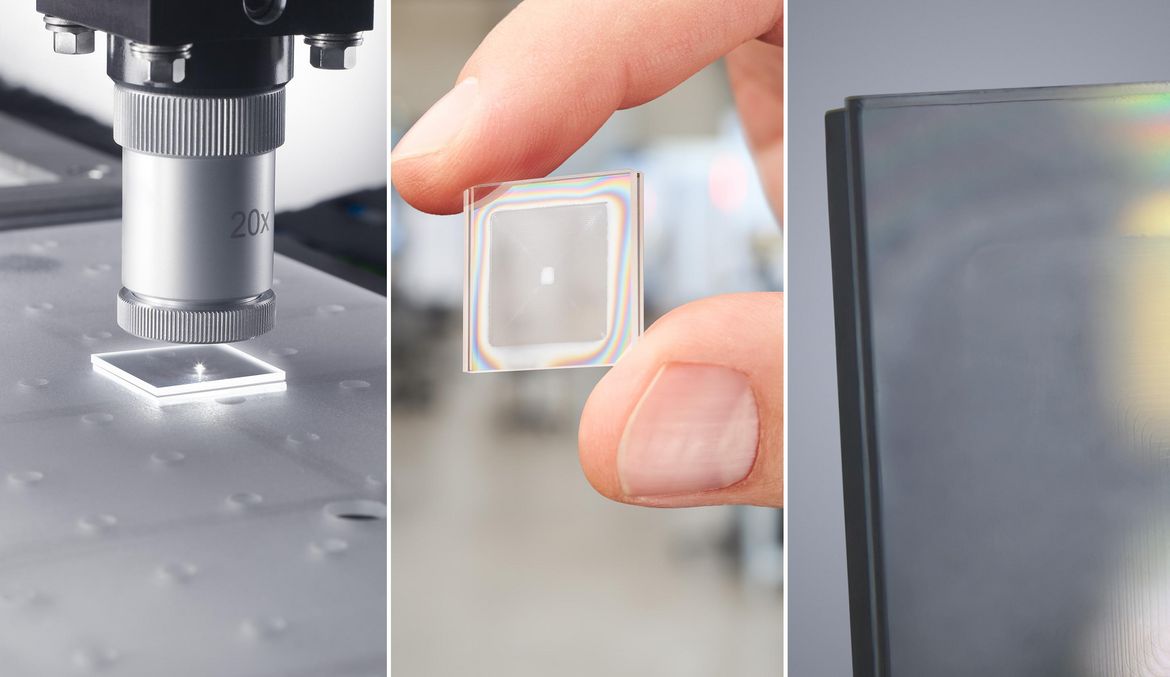

Cutting ultra-thin glass

Laser modification cutting allows ultra-thin glass (50 µm) to be cut with the highest edge quality. This significantly increases the rigidity.

Glass welding

TRUMPF TOP Weld optics focus femtosecond-long laser pulses to weld glass to glass or glass to metal with high precision. The result is a high-tensile and practically invisible bond.

Surface structuring

Ultrashort pulse lasers enable a variety of different processes. By varying the laser parameter set, metal surfaces can be cleaned, structured and engraved.

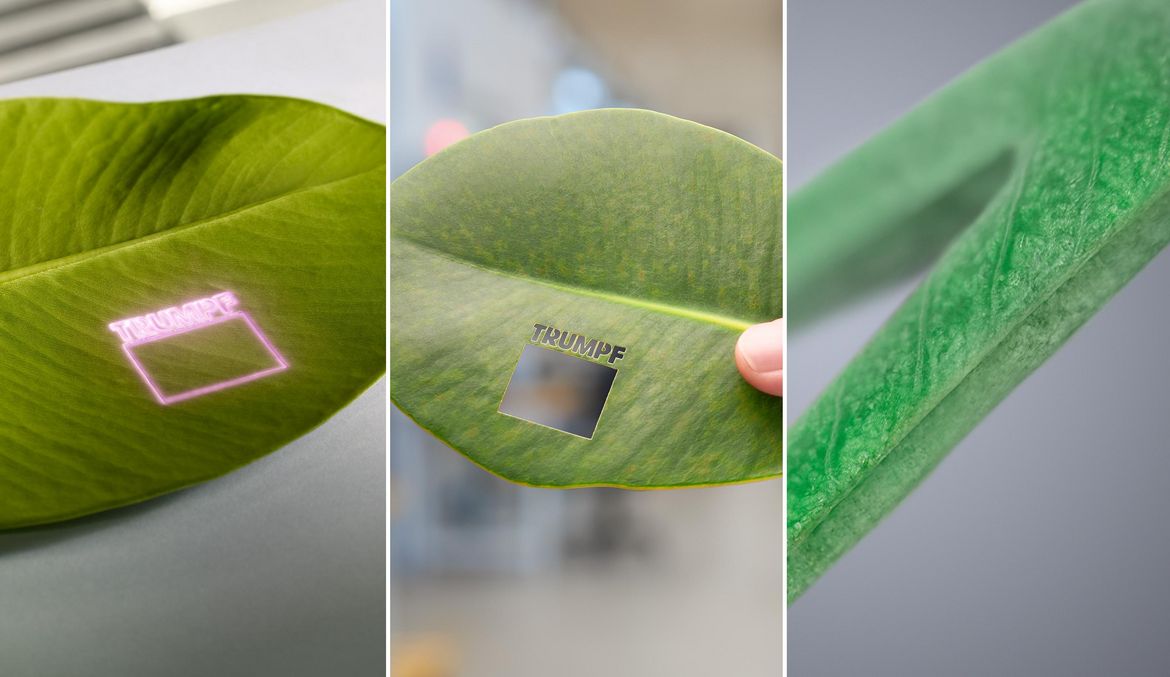

Cutting organic material

The combination of ultrashort durations with high intensity enables microprocessing with incomparable precision. Even highly sensitive organic material can be cut without damaged or burned edges.

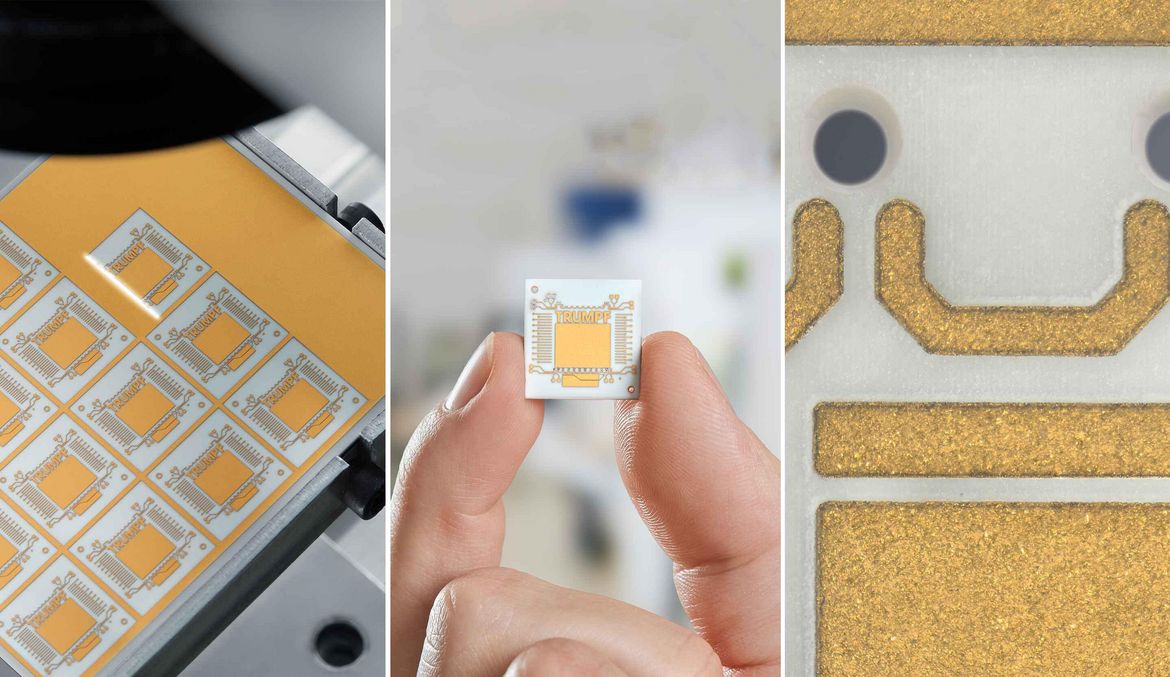

Ablation of gold and ceramics

The TruMicro 2030 cuts and processes technical high-performance ceramics for performance electronics and consumer electronics. Precise ablation creates conductor tracks and eliminates the need for etching processes, representing a step forward in terms of environmental protection.

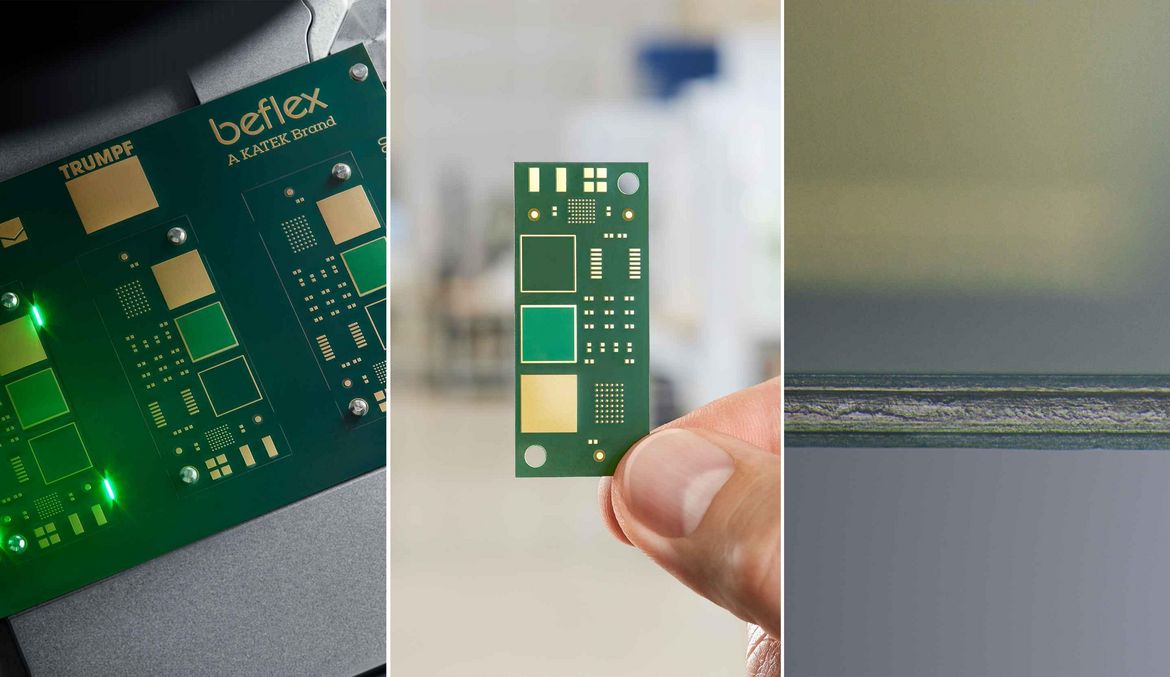

Cutting printed circuit boards

The use of the green wavelength enables the processing of flexible printed circuit boards (FPC) for the electronics industry and medical technology. The laser guarantees fast and precise cutting without producing a heat-affected zone. Optimal edge quality is attained, even when working with plastics.

Cutting and ablation of lumen tubes

The precise cutting and ablation of lumen tubes with ultrashort pulse lasers facilitates their use in medical technology. The processing shows no discoloration or melting of the cutting edges or markings.

Invar cutting

The TruMicro Series provides precise cuts of intricate geometries from ultra-thin films measuring less than 100 µm. These form the basis for efficient stator and rotor stacks in electric motor production.

|

TruMicro 2030

|

TruMicro 2230

|

|

|---|---|---|

| Laser parameters | ||

| Average output power | 20 W | 10 W |

| Beam quality (M²) | < 1.2 | < 1.3 Optional < 1.2 |

| Wavelength | 1030 nm | 515 nm |

| Pulse duration | < 350 fs - 20 ps | < 350 fs |

| Maximum pulse energy | 100 µJ | 10 µJ Optional 25 µJ or 50 µJ |

| Maximum repetition rate |

2000 kHz

QCW-Modus: 50000 kHz |

1000 kHz Optional 400 kHz for 25 µJ pulse energy or 200 kHz for 50 µJ pulse energy |

| Structural design | ||

| Dimensions of laser head (W x H x D) | 570 mm x 360 mm x 180 mm | 570 mm x 360 mm x 180 mm |

| Dimensions of supply unit (W x H x D) | 510 mm x 485 mm x 180 mm | 510 mm x 485 mm x 180 mm |

TruControl

TruControl is the quick and easy-to-use control for TRUMPF solid-state lasers. It regulates the laser power in real time in order to deliver reproducible results. TruControl manages, controls and visualises the interface configuration. You benefit from a uniform control architecture across all laser technologies. The lasers have interfaces to control intelligent TRUMPF optics, such as monitored CFO focusing optics or PFO scanner optics. You can program the processing optics easily using the laser control system. The remote support service provided by TRUMPF means that you receive off-site support within seconds. This will allow you to avoid service calls or be as prepared as possible and increase the availability of the laser device.

With useful added options, you can work even more efficiently and with more process reliability with the lasers in the TruMicro Series 2000.

Forego elaborate free-beam guidance and significantly simplify the machine design: instead of the free-beam guidance, the laser pulses are guided through the hollow core fibres from the laser source to the optics. The laser can be integrated in the processing machine much more flexibly thanks to this thermal and mechanical decoupling between the TRUMPF laser and the corresponding optics. The steel and pulse properties remain unaffected.

Have your laser monitored by our TRUMPF experts and algorithms. We contact you proactively at the first signs of anything unusual. This avoids unplanned downtimes in your production.

If complex geometries are processed with scanners, for example when cutting polymer films, the acceleration and brake paths of the scanner lead to varying spatial intervals of the ultrashort laser pulses on the material. This means that the processing quality depends on the processing geometry. On the other hand, the repetition rate is adapted to the scan speed with the "Flexible Pulse on Demand" option, facilitating constant pulse intervals. This not only means that the process result is independent of the processing contour, but that the process time is decreased as well.

TRUMPF offers you all the components you need for beam guidance from the laser to the workpiece. This also applies for various focusing optics which have proven themselves to be precise and reliable over many years of industrial use. The optics can be easily integrated – both in stand-alone processing stations as well as in complete production lines. The modular structure enables the optics to be continually adapted to the laser types as well as the different processing situations.

TOP Cleave cutting optics

The TOP Cleave-2 PRO focusing optics are processing optics for highly dynamic cutting of transparent materials, such as glass or sapphire.

TOP Weld processing optics

The innovative processing optics for welding transparent materials without intermediate layers.

Scanner

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.