Reliable ultrashort pulse lasers designed for the highest demands in series production

The ultrashort pulse lasers in the TruMicro Series 6000 are proven, industrially tested solutions that are ideally suited to demanding series production systems.

Using slab technology, they generate laser pulses that can be linearly amplified to very high pulse energies with flexibility. The broad range of adjustable parameters also enables the optimal execution of complex processes.

These robust, stable lasers are used in numerous 24/7 field operations, where they impress with their high load capacity. They are ideal for applications including cutting OLED displays or slitting flexible printed circuit boards in the consumer electronics industry.

Optimum energy and timing on the workpiece, e.g. controlled by the scanner.

The ultrashort pulse lasers generate high average power due to high pulse energies.

Whether IR, green or UV – selecting the correct wavelength means the most varied of materials can be processed in the best possible way.

With the TruMicro Series 6000, you will receive industrial, high-quality series products based on established components.

The internal power control ensures stable output parameters and a homogeneous process result.

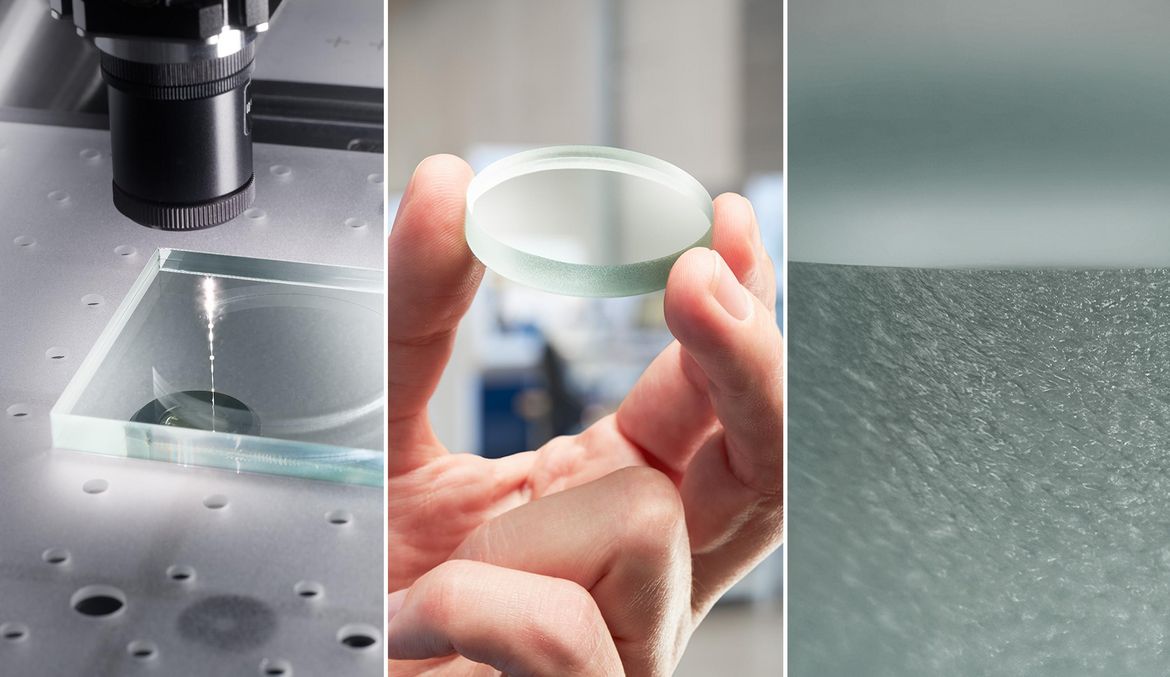

Glass modification

Extreme thicknesses greater than 10 mm can be efficiently processed and then cut with TRUMPF TruMicro lasers and TOP Cleave optics. After cutting, it is not necessary to post-process the cutting edge, such as by grinding or polishing.

Cutting copper foil

The finest structures to the dimension order of micrometers can be cut precisely with a minimal heat-affected zone. This is true even for materials with high reflectivity such as copper alloys.

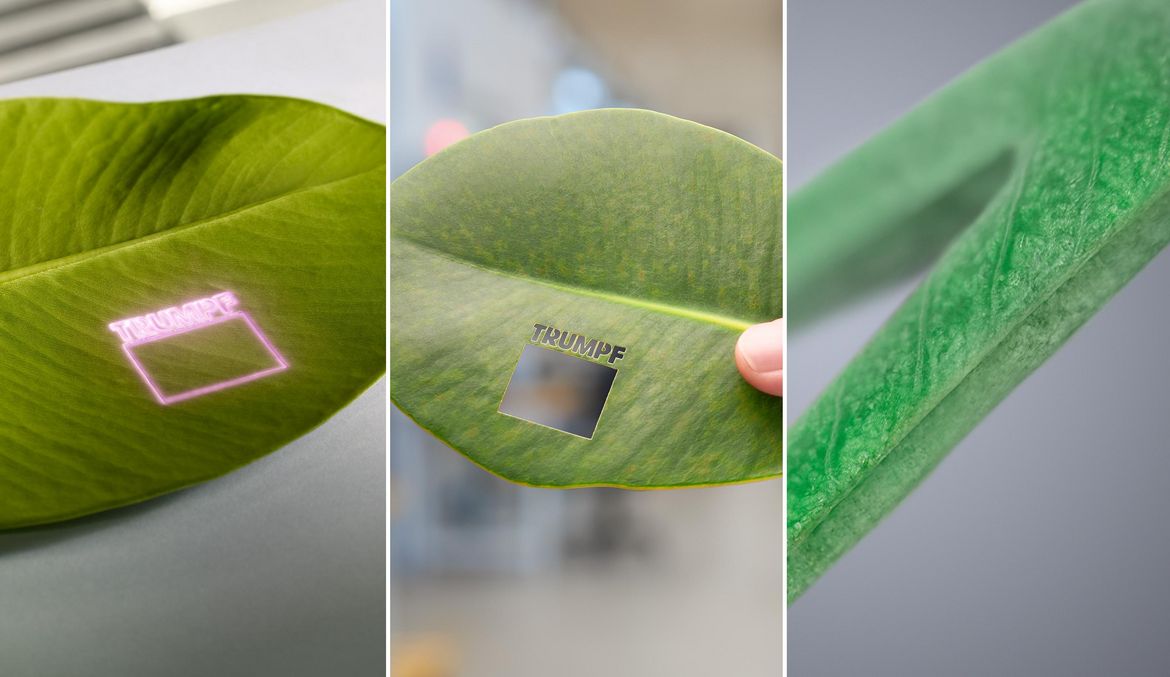

Cutting organic material

The combination of ultrashort durations with high intensity enables microprocessing with incomparable precision. Even highly sensitive organic material can be cut without damaged or burned edges.

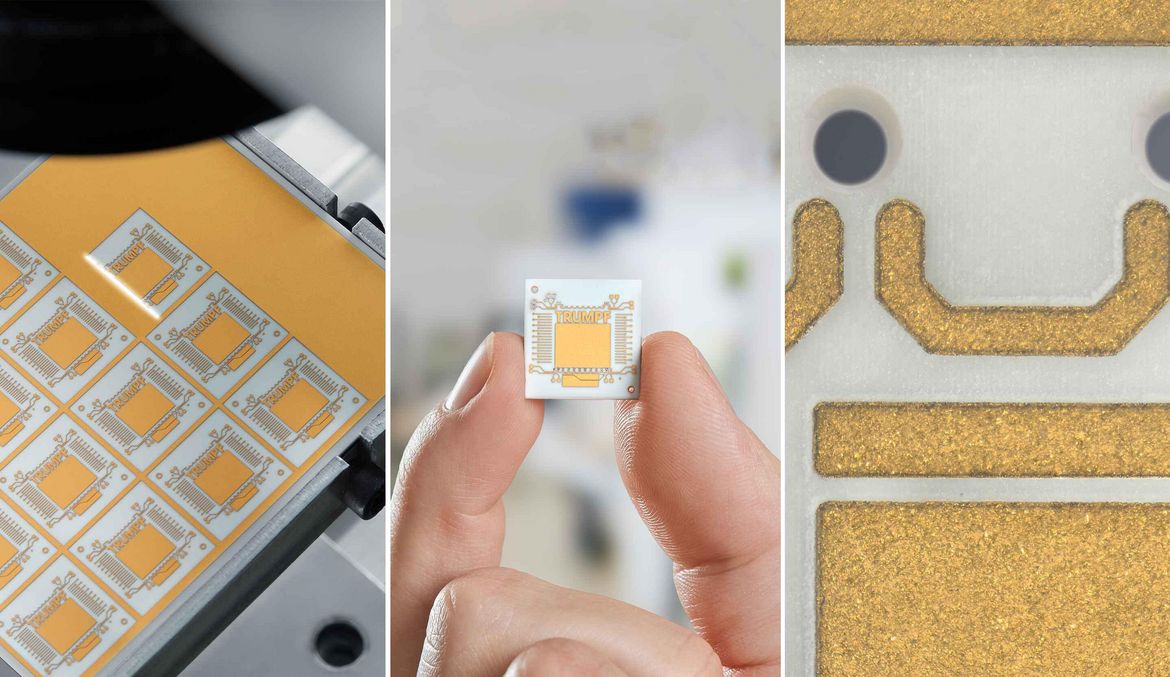

Ablation of gold and ceramics

The TruMicro 6020 cuts and processes technical high-performance ceramics for performance electronics and consumer electronics. Precise ablation creates conductor tracks and eliminates the need for etching processes, representing a step forward in terms of environmental protection.

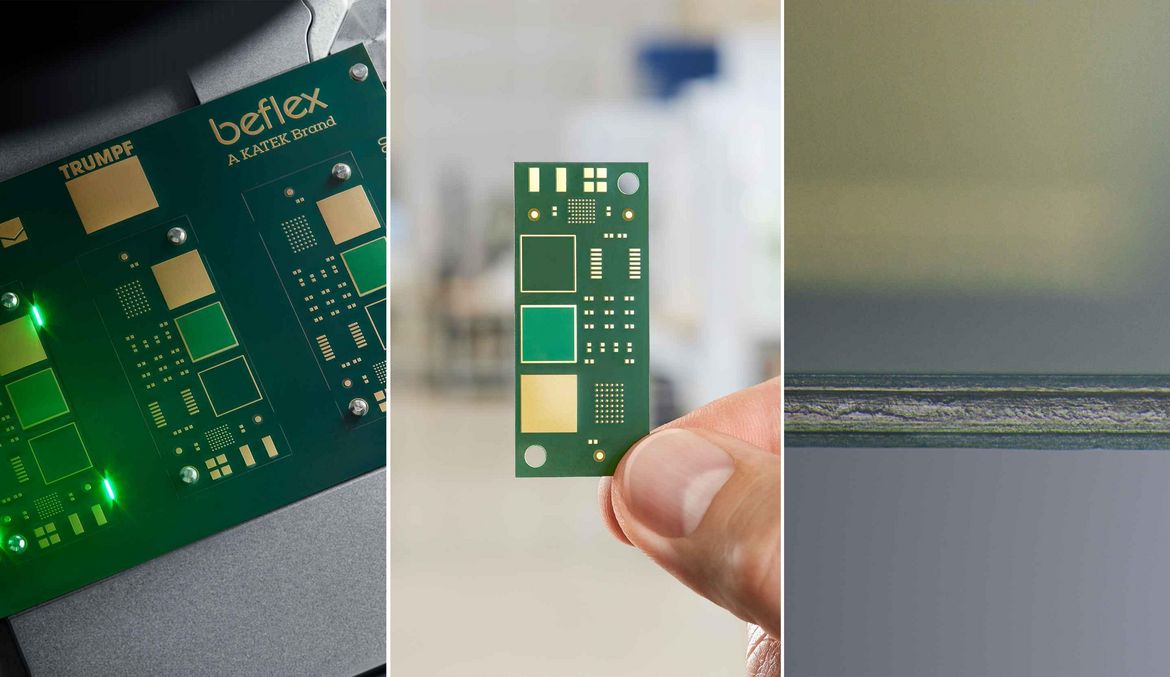

Cutting printed circuit boards

The use of the green wavelength enables the processing of flexible printed circuit boards (FPC) for the electronics industry and medical technology. The laser guarantees fast and precise cutting without producing a heat-affected zone. Optimal edge quality is attained, even when working with plastics.

Cutting wood

The TruMicro 6220 cuts wood with precision. Thanks to advanced ultra-short pulse technology, organic materials can be processed without leaving any residue.

|

TruMicro 6020

Compare product

|

TruMicro 6030

Compare product

|

TruMicro 6220

Compare product

|

TruMicro 6320

Compare product

|

|

|---|---|---|---|---|

| Laser parameters | ||||

| Average output power | 200 W | 300 W | 100 W |

30 W (< 500 fs) or

50 W (< 850 fs) |

| Beam quality (M²) | < 1.3 , optional < 1,2 | < 1.3 | < 1.3 , optional < 1,2 | < 1.3 , optional < 1.2 |

| Wavelength | 1030 nm | 1030 nm | 515 nm | 343 nm |

| Pulse duration |

< 850 fs oder

< 5 ps |

850 fs | < 850 fs | < 500 fs or |

| Maximum pulse energy |

200 µJ bei 1 MHz oder

2 mJ bei 100 kHz |

200 µJ bei 1 MHz

2 mJ bei 100 kHz |

100 µJ bei 1000 kHz |

37.5 µJ at 800 kHz (30 W)

50 µJ at 1 MHz (50 W) |

| Maximum repetition rate | 2000 kHz (single pulse picking) |

3000 kHz

50000 kHz (QCW-Modus) |

2000 kHz | 2000 kHz |

| Structural design | ||||

| Dimensions of laser head (W x H x D) | 600 mm x 366 mm x 735 mm | 600 mm x 366 mm x 735 mm | 600 mm x 366 mm x 735 mm | 600 mm x 366 mm x 735 mm |

| Dimensions for basic device size (W x H x D) | 446 mm x 915 mm x 725 mm | 446 mm x 915 mm x 725 mm | 446 mm x 915 mm x 725 mm | |

| Dimensions of supply unit (W x H x D) | 446 mm x 915 mm x 725 mm | |||

| Installation | ||||

| Ambient temperature | 15 °C - 35 °C | 15 °C - 35 °C | 15 °C - 35 °C | 15 °C - 35 °C |

|

TruMicro 6020

|

TruMicro 6030

|

TruMicro 6220

|

TruMicro 6320

|

|

|---|---|---|---|---|

| Laser parameters | ||||

| Average output power | 200 W | 300 W | 100 W |

30 W (< 500 fs) or

50 W (< 850 fs) |

| Beam quality (M²) | < 1.3 , optional < 1,2 | < 1.3 | < 1.3 , optional < 1,2 | < 1.3 , optional < 1.2 |

| Wavelength | 1030 nm | 1030 nm | 515 nm | 343 nm |

| Pulse duration |

< 850 fs oder

< 5 ps |

850 fs | < 850 fs | < 500 fs or |

| Maximum pulse energy |

200 µJ bei 1 MHz oder

2 mJ bei 100 kHz |

200 µJ bei 1 MHz

2 mJ bei 100 kHz |

100 µJ bei 1000 kHz |

37.5 µJ at 800 kHz (30 W)

50 µJ at 1 MHz (50 W) |

| Maximum repetition rate | 2000 kHz (single pulse picking) |

3000 kHz

50000 kHz (QCW-Modus) |

2000 kHz | 2000 kHz |

| Structural design | ||||

| Dimensions of laser head (W x H x D) | 600 mm x 366 mm x 735 mm | 600 mm x 366 mm x 735 mm | 600 mm x 366 mm x 735 mm | 600 mm x 366 mm x 735 mm |

| Dimensions for basic device size (W x H x D) | 446 mm x 915 mm x 725 mm | 446 mm x 915 mm x 725 mm | 446 mm x 915 mm x 725 mm | |

| Dimensions of supply unit (W x H x D) | 446 mm x 915 mm x 725 mm | |||

| Installation | ||||

| Ambient temperature | 15 °C - 35 °C | 15 °C - 35 °C | 15 °C - 35 °C | 15 °C - 35 °C |

TruControl

TruControl is the quick and easy-to-use control for TRUMPF solid-state lasers. It regulates the laser power in real time in order to deliver reproducible results. TruControl manages, controls and visualises the interface configuration. You benefit from a uniform control architecture across all laser technologies. The lasers have interfaces to control intelligent TRUMPF optics, such as monitored CFO focusing optics or PFO scanner optics. You can program the processing optics easily using the laser control system. The remote support service provided by TRUMPF means that you receive off-site support within seconds. This will allow you to avoid service calls or be as prepared as possible and increase the availability of the laser device.

The precise time definition of the individual laser pulses is relevant for an optimum process result. The exact time and pulse energy per individual pulse can be set due to the linear slab amplification. Particularly in combination with a scanner, this function can provide equidistant pulses on the workpiece even in the case of acceleration or deceleration.

Have your laser monitored by our TRUMPF experts and algorithms. We contact you proactively at the first signs of anything unusual. This avoids unplanned downtimes in your production.

Seamless integration of many TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

TOP Cleave cutting optics

The TOP Cleave-2 PRO focusing optics are processing optics for highly dynamic cutting of transparent materials, such as glass or sapphire.

TOP Weld processing optics

The innovative processing optics for welding transparent materials without intermediate layers.

Scanner

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.