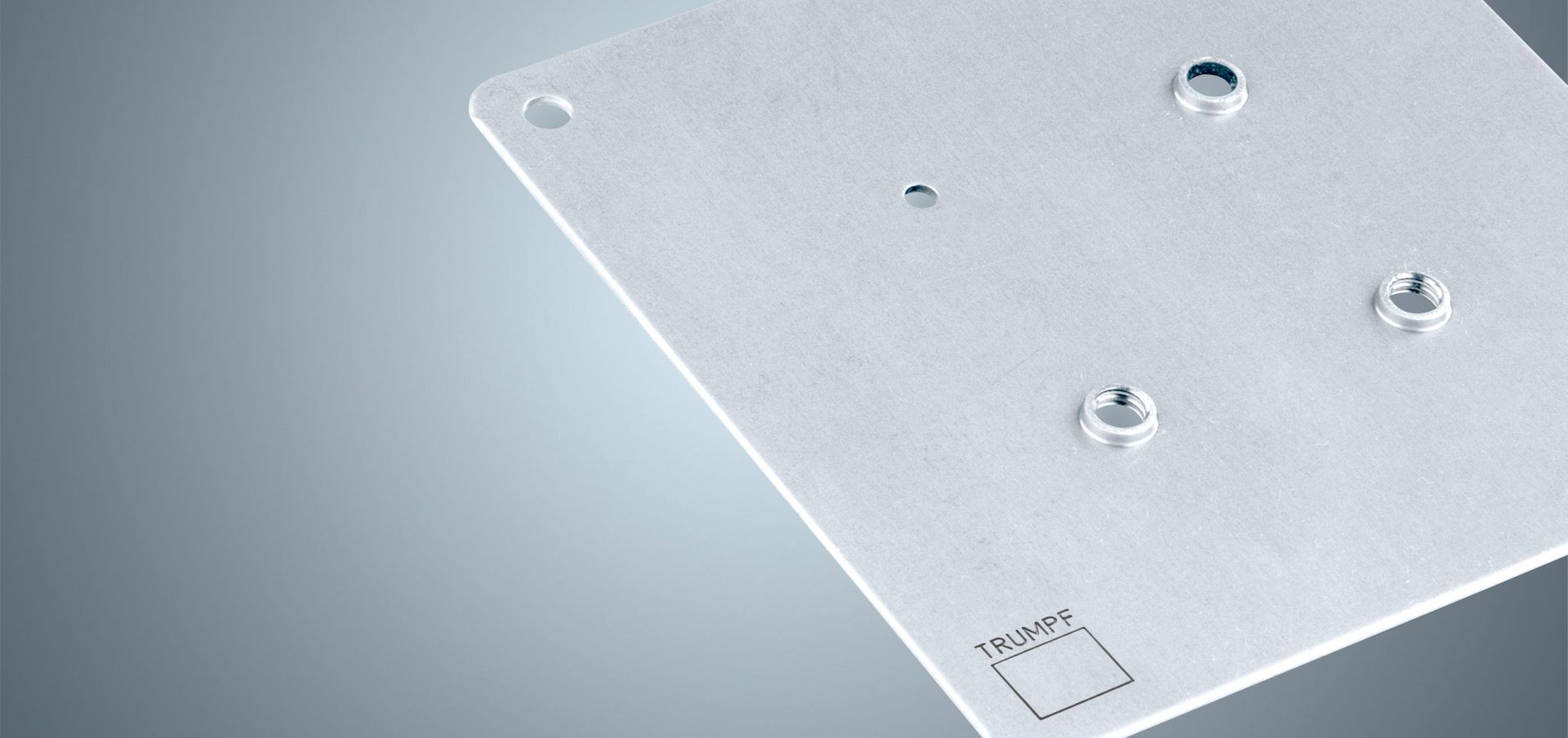

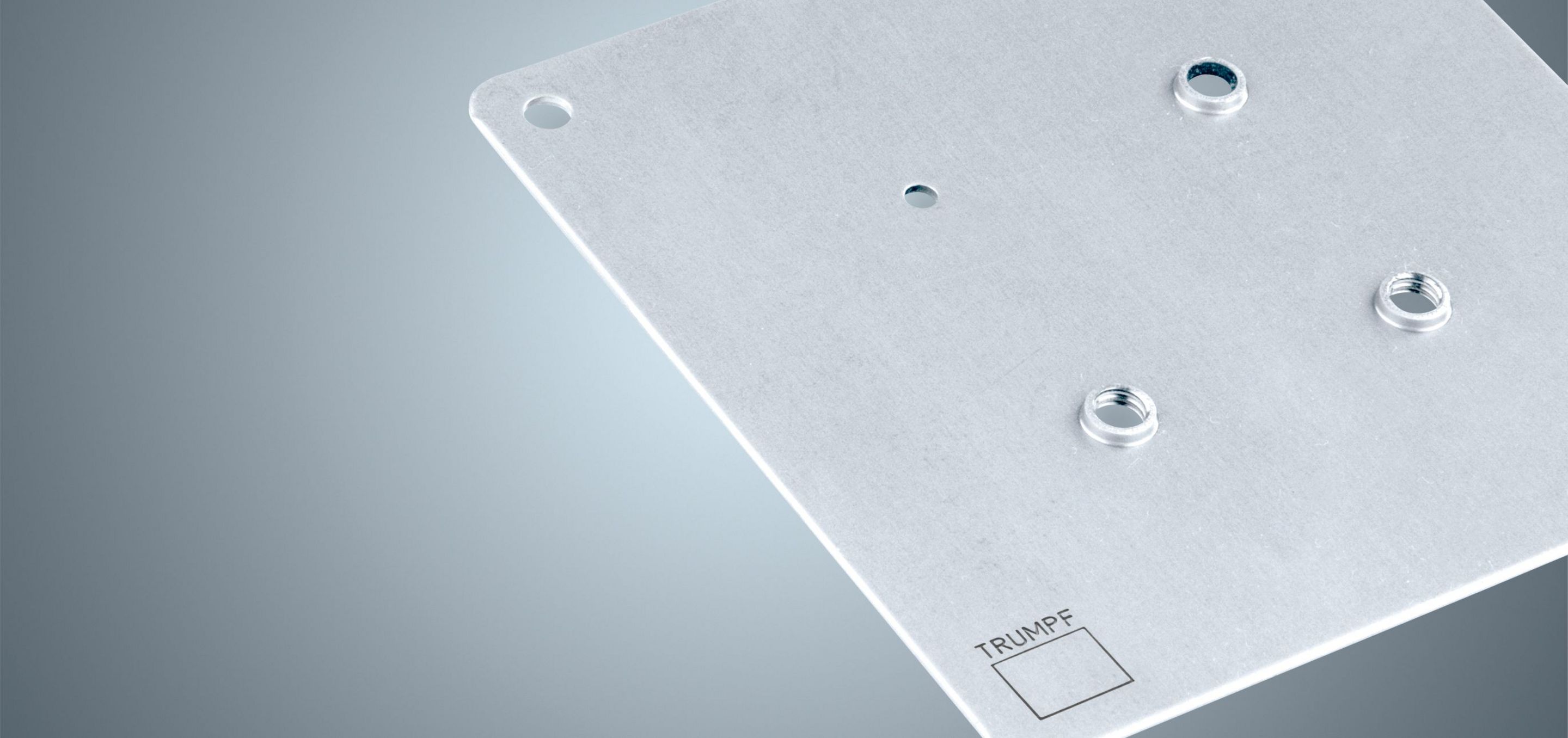

Reduce your throughput times and minimise storage space for intermediate products by simply forming threads directly on your punching or punch laser machine. With the tapping tool, you can create threads in a pre-processed punched hole or extrusion. In contrast to thread cutting, no chips are formed during this process as the material is displaced during the forming process and not cut. The threads which are formed have a higher strength compared to cut threads and also impress with a high fit accuracy.

Forming threads without chips

Using the tapping tool, you can create threads directly on the machine. As the material is displaced and not cut during the forming process, there are no chips.

In one operation

Complete processing directly on the machine reduces part costs.

High thread strength

A high thread strength is obtained due to the strain hardening of the material.

Flexible use

The tapping tool can be used for different thread sizes.

Perfected precision

The tool impresses with its high fit accuracy.

Tool options

Contact