The honeymoon is over for electric carmakers. Or perhaps it never happened in the first place? After all, haven’t the manufacturers of electric vehicles always had it tough?

The first people to build electric cars were seen as researchers, idealists – even pioneers. At first, they were laughed at or simply ignored. They struggled against skepticism over technical feasibility, range and their business model. And they always had to rely on buyers being willing to spend a few thousand more. The only thing they never had to worry about was volume production.

To build electric vehicles, or EVs, you needed patience, incredibly optimistic investors, nerves of steel and a market. What you didn’t need was a solution to orders like “I’ll take 100,000 of those parts, please. Every month.” Budgets were tight, but with such low-volume production nobody had to rack their brains about whether method X would save half a cent at each step of the process as compared to method Y.

China leads and the rest follow

But now the honeymoon is over. Electric cars are set to become mainstream. Washington, DC and most governments in Europe have given them their backing and started plowing money into this vision of the future. Yet in some ways it hardly matters what the Europeans and Americans are doing, because EV trends will ultimately be set by the world’s largest automobile market, China.

And here the die has already been cast: in a country with 30 million new car registrations every year, the government has decreed that, starting in 2019, carmakers will have to make ten percent of their sales from electric vehicles. Even subdued forecasts suggest that half of all new cars worldwide will be electrified as early as 2025 – in other words all-electric or hybrid models, with or without charging sockets.

Today’s parents driving their newborn babies home from the hospital in internal combustion engine cars will almost certainly be taking them to school in an electric car seven years from now.

Rapid change offers opportunities

So the time has come to develop methods of mass production. The good news is that this accelerated upheaval in drive technology offers real opportunities to newcomers. The question is still open as to where EV value creation will lie in the future, and who will be in the right place to profit from it.

It’s perfectly possible, for example, that today’s big automakers will limit themselves to designing the body and interior of their vehicles in ten years’ time while simply buying in the batteries and electric motors.

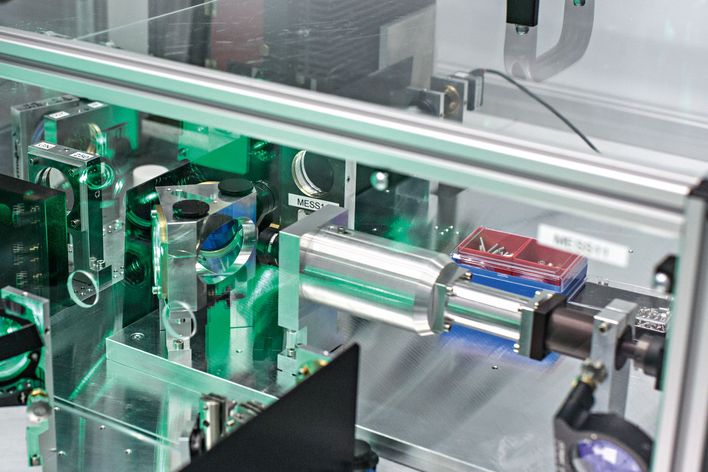

However things pan out, what matters now is being smart enough to develop highly efficient manufacturing methods for EV-specific components. Over the past 30 years, automakers have clearly shown that the laser is a material processing tool they can use to execute flexible, high-precision steps on the factory floor in next to no time.

And many of the key car components – body, interior, lightweight components, brakes, etc. – aren’t going anywhere. Even in 2025, electric cars will still need doors, and the carmakers already know how to make them efficiently. But now three new fronts are opening up: batteries, electric drives and high-power electronic systems. EV sales are currently running at about two million a year, and forecasts suggest that will rise to 40 million in just a few years’ time.

To keep up, many industry players will once again have to rely on laser material processing.

Battery times three

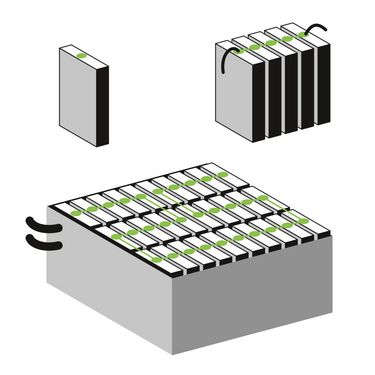

What we loosely refer to as a battery is, in fact, a fairly complex entity. There are actually three components that hold the key to the efficient manufacturing of energy storage devices for electromobility: battery cells, battery modules and battery packs.

Lithium-ion battery cells are built up in layers: copper foil and coated aluminum layered together with the electrode foils of lithium metal oxide (cathode) and graphite (anode). Each of the different foils is approximately 100 microns thick, and the easiest way to cut them is with a short-pulse laser. After adding the liquid electrolyte, the next step is to seal the cell with a cap and fit a pressure-relief valve. It is essential that the welds completely seal the cell, but it is equally important that they do not penetrate too deep since this would render the cell useless. So, once again, battery-cell manufacturers turn to the delicate and reliable touch of the laser.

Today’s market for battery cells is largely divided up between volume manufacturers in China, South Korea and Japan. In contrast, the market for battery modules is still open – so far, no standards have been set for the rest of the process.

Tackling a dilemma with wobbling

Normally, between 9 and 12 cells are grouped together to form a battery module. For the battery module to work as a unit, the battery cell terminals must be interconnected. This is achieved using thin metal strips, generally made from 0.3-millimeter sheets of copper or aluminum. Known as leads, or tabs, these strips carry electric current into or out of the cells and are lap-welded.

That may sound simple, but it puts workers in a tricky situation: if they accidentally extend a weld into a cell that is packed with chemicals, or heat it to more than 80 degrees Celsius, the battery burns out and has to be scrapped. That’s why it’s so important to weld the seam with a carefully judged penetration depth, as close as possible to the minimum needed for a stable, lasting connection.

Of course the weld seam’s main purpose is not to hold the parts together, but to ensure an efficient flow of current. That, in turn, requires low resistance and a sufficiently large contact area: basically the bigger, the better.

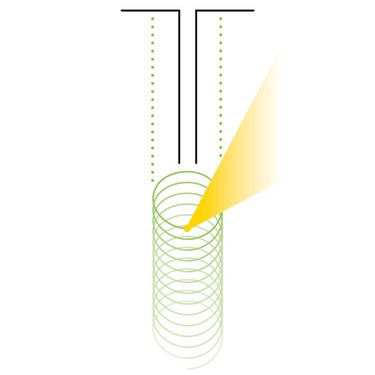

Scanner-based laser welding solves this dilemma with “wobbling.” The scanner system automatically positions the small laser spot in the correct place and oscillates the beam over the metal strip. This creates a very fine, very long seam which produces a large contact area.

An electric car battery basically consists of three elements: individual battery cells are packed together to form battery modules. In the vehicle itself, multiple modules are combined to create a battery pack. (Image: Gernot Walter)

Wobbling is a technique that involves oscillating a scanner-guided beam in a spiral motion. This effect can be exploited to create fine welds with a large contact area for battery modules and busbars, without requiring any filler material. (Image: Gernot Walter)

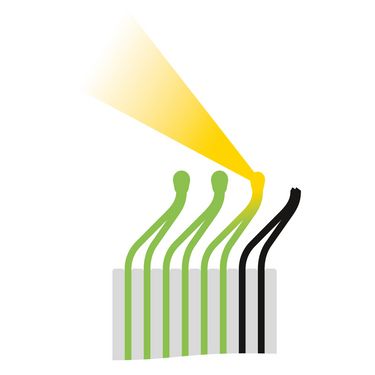

Hairpin-like windings instead of coil windings in an electrical motor: Hairpin-like windings made from rectangular copper wire inserted in a stator. The protruding ends are pressed together and laser welded with a scanner system. (Image: Gernot Walter)

The second compelling feature of scanner welding is the tremendous speed the laser can achieve by working at a distance. No cumbersome steps are required to move the tool to the welding point – it simply executes numerous welds a minute as it flies by. The result is precisely the combination of short cycle times and high quality that automakers relish.

Connecting the busbar contacts poses a problem similar to that of the cell tabs. The busbar connects up all the battery cells in a module and collects all the current. The contact welding process often requires the joining of dissimilar materials – in this case, the highly reflective materials aluminum and copper. Disc lasers can easily deal with the sustained back reflections and, once again, scanner-based welding with a disk laser and wobbling prove to be the ideal solution.

The battery pack is what ends up being installed in the vehicle. To achieve the ideal center of gravity for the vehicle, all the battery modules are packed into a shallow compartment on the underbody of the vehicle, just a few centimeters above the asphalt. The pack must be completely sealed to avoid any chemicals dripping onto the ground and to prevent water from the road spraying into the compartment. And, just like a gas tank, it needs to remain intact not just under normal driving conditions, but also in the event of a crash.

The manufacturers weld together the five-sided, tightly sealed compartments from steel components, aluminum and other sheet metals using a highly productive disc-laser welding technique. Once the compartment is finished, they glue the lid onto it. The laser plays a role here, too, cleaning and structuring the surface to prepare it for gluing. Even when companies start producing battery packs in higher volumes, the laser will still have its place on the factory floor. Even though standard battery compartments will probably be formed by deep drawing, lasers will still be used to weld parts for model variants and special short-run series, such as convertibles with a lowered chassis that need a flatter battery compartment than standard models.

Making electric motors faster

As the industry seeks ways to accommodate volume production, companies are also starting to reconsider some of the traditional, yet sluggish, manufacturing methods currently used for electric motors. One example is the coil. Normally, the stators in electric motors are provided with a winding of copper wire. Each individual slot in the stator is wrapped in a winding that goes in and out, in and out, almost like knitting! That takes time – and it’s tough to automate.

The auto industry considers this process to have reached the limits of its productivity and is banking on a new technique known as hairpins. This involves using a compressed-air pistol to fire a rectangular copper wire similar to a hairpin straight into each slot. This method is several times faster – just one shot per slot – and it completely fills the space with copper, which increases the motor’s efficiency. The protruding parts of the hairpin on both sides are then pressed onto each other using a mask, or are jammed or twisted together.

The problem is that the hairpins are sometimes slightly out of alignment with each other after this process, with unsightly gaps in certain places. That’s when scanner welding comes back into play: a camera in the laser optics determines the orientation of the objects within the space and finds the ideal welding point within just a few fractions of a second. The beam focus oscillates and, in little more than a minute, all 200 of the welds required for each motor are finished – and the laser is ready to weld the connections for the next motor.

The second benefit of using high-precision scanner laser welding for hairpins is that it reduces the overhang of the weld seam to almost zero. The slots and hairpins can move closer together, and that means the motor takes up less space.

At this point the copper hairpins go under the laser for the second time, having already had their insulating enamel removed by a pulsed nanosecond laser earlier in the process, either directly on the coil or before winding. Mechanical methods to remove the enamel – such as planing and milling – can no longer keep pace with the required level of productivity.

Mobile power electronics

For the first time, power electronics such as chargers, transformers, rectifiers and battery-management systems are making massive inroads into the realm of cars and their charging infrastructure. While the electronics in cars powered by fossil fuels had to make do with a 48-volt battery, electric cars will soon be using voltages as high as 800 volts.

Once again, the companies that manufacture these kinds of power electronics are faced with the dilemma of how to mass-produce these components – and how to make them as small as possible. That’s because every millimeter counts for carmakers when it comes to battery-pack size and installation space, and engineers may decide that even the millimeter-sized contact pins are too big. What’s more, weld spatter can become a serious problem for contact connectors: a large spatter droplet could easily consign the virtually finished component to the scrap heap.

Even worse, spatter could end up stuck to the component, initially harmless, but then suddenly come loose later on when the car is in motion – causing a short circuit and bringing the car to a standstill.

The problem is that space is tight when it comes to welding electronic components, so there is simply no space for devices designed to intercept spatter. That’s why engineers opt for a disk laser. Combined with special technology that simultaneously overlays two welding foci, a disk laser can create virtually spatter-free welds even in small, cramped environments.

The laser welds directly in the groove, which keeps the contact pins below three millimeters. More valuable millimeters shaved off the size of the components – and every little bit helps!

Thinking electric

A whole army of professors, think tanks, companies and elected officials are pondering the future of mobility; they often come to very different conclusions. But one thing they have in common is the belief that all the most promising solutions for personal transportation are electric, from car sharing to autonomous driving. Most industry trendspotters have simply forgotten about sputtering, fossil-fuel cars – a sure sign that their era is coming to a close.

At the same time, however, personal mobility is more in demand than ever before in human history. The next five years will reveal the big winners and losers in the transition to mass-produced electric motors. It already seems clear, though, that the idea of electric cars for everyone will ultimately mean more volume and series production processes that rely on lasers.