Professor Zhong, superhydrophobic surfaces would, theoretically speaking, come in very handy in industry. But as things stand their use in industrial applications is very limited. Why is that?

We’re looking at two challenges here. Most of today’s surfaces lack sufficient durability because their nanostructures are so susceptible to wear and damage through contact with solid particles. Currently, there is not a single superhydrophobic surface on the market robust enough to meet the strict abrasion, impact and adhesive strength standards required for use in industrial applications.

And what’s the other issue?

The production process. Even if somebody developed a sufficiently robust surface, they would still need a scalable production process. It’s no secret that speed is the name of the game in industry, so a quick and cost-effective solution for producing large-scale surfaces is a must. That’s just not possible when processes such as chemical etching or plasma coating are involved.

You managed to tackle both problems in one go. How?

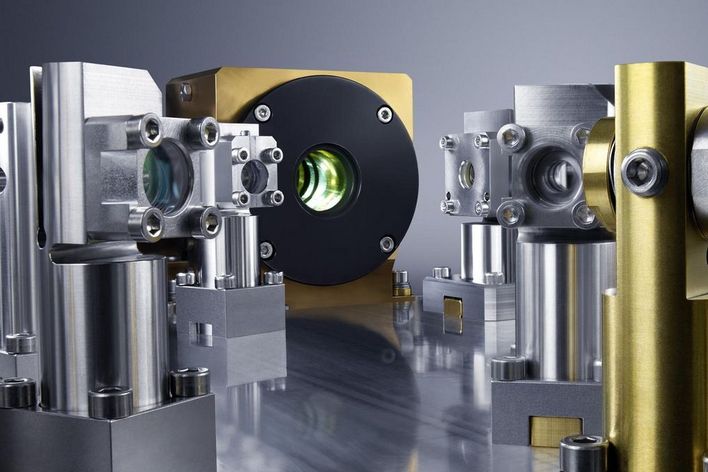

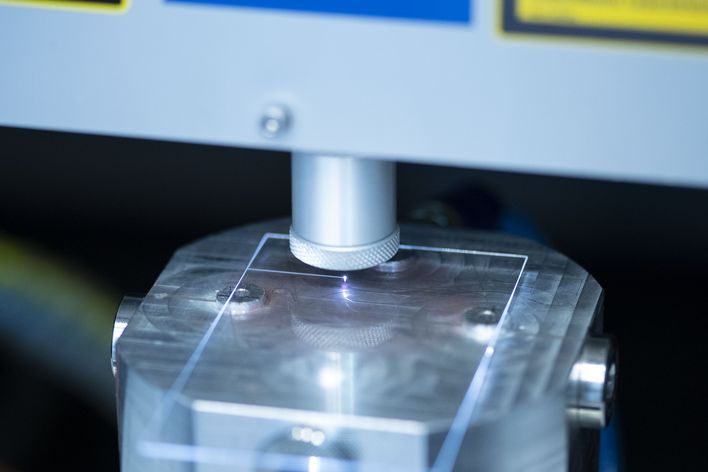

Throughout my career, I’ve gained a lot of experience with lasers used for surface processing. Needless to say, I know what these impressive tools can do. So, when it comes to producing nanostructures, I firmly believe the ultrashort pulse laser is the best tool for the job. Thanks to a technique known as cold processing, the laser can supply the high level of energy required without causing heat influence zones to form, which are counterproductive. This approach works with a range of different materials suitable for use in industry. So, after liaising with my team, we opted for a TruMicro 5000 femtosecond laser from TRUMPF. It delivers an average power of 40 watts, which was sufficiently high for our research purposes.

How does your technique of generating nanostructures with a laser differ from others?

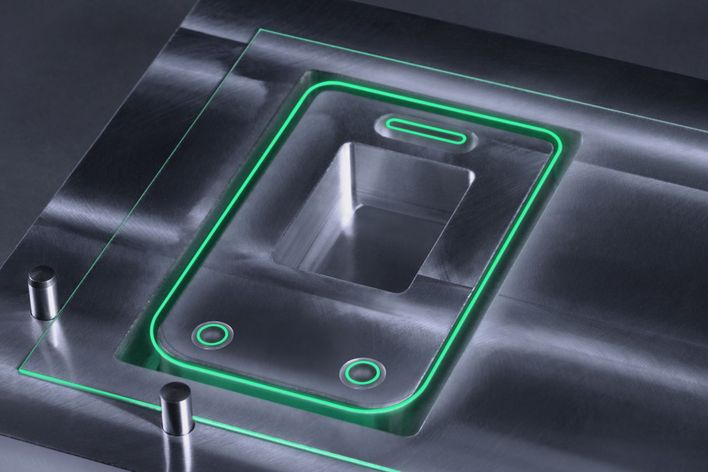

The most important difference is that we don’t focus exclusively on the nano-level. To ensure we meet all the surface requirements, we produced a hierarchical structure with two levels: micro and nano. At the micro level, we created tiny cones with the height and spacing we wanted on the surface. The nano-structures themselves sit on of the outside of these micro cones to form the second level. This approach doesn’t impair the surface’s superhydrophobic properties – in fact, it does the opposite. We work with a contact angle of 163 degrees. It’s really quite amazing!

And that makes the surface more durable?

Yes, precisely, because the micro structure protects the nanostructure. The tips of the micro cones collectively intercept objects and particles that could come into contact with the superhydrophobic surface. This prevents any harmful matter from reaching the nanostructures in the first place. We pursued a rigorous test campaign covering all conceivable scenarios and always came out with the same result: our hierarchical structure is set to become the first superhydrophobic surface in real-world applications.

What are the next steps?

We’re currently looking to identify industry partners – companies we could join forces with to scale up our method for real-world use cases. I don’t expect we’ll have any problems on that front. Existing tools and approaches, such as polygon scanners or multi-beam scanning, will enable us to bring our processing speed and surface up to the required level. Give it two years and I’m confident that our technique will be ready to go.

Professor Minlin Zhong from Tsinghua University in Beijing, China.

According to him, superhydrophobic surfaces are on the cusp of a breakthrough in industry.