One of the first industrial applications for a laser was the welding of watch springs for wristwatches. Haas – a Schramberg-based manufacturer located in Germany’s Black Forest region – first started examining the possibilities back in 1964. Welding watch springs required only low laser power, as the steel springs to be welded measured scarcely one millimeter across.

Soon thereafter Haas began to develop its own beam sources; in 1971 it presented its first proprietary solid-state laser: an Nd:YAG (neodymium-doped yttrium aluminum garnet) rod laser. Starting in 1992, TRUMPF started to invest in Haas Laser GmbH to expand its own beam source product range, which at the time consisted primarily of CO2 lasers. Since then Haas Laser has turned into TRUMPF’s Schramberg site, where solid-state lasers are developed and manufactured.

Mechanical wristwatches consist of a multitude of minuscule components that require micrometer-range accuracies. Mechanical machining of these parts is at best difficult, and at worst simply impossible. Under these circumstances, laser technology is predestined for use in diverse manufacturing processes for all subassemblies.

Quartz watches and smart watches

In addition to the previously mentioned laser-based processes used to manufacture mechanical watches, lasers also play an important role in the production of quartz watches or the new wrist computers known as smart watches. Both mechanical and quartz watches share many of the same components. These include the hands, watch faces and appliqués, watchbands, casings, bezels and also the watch crystal. In smart watches, the production of computer chips counts, too, since laser technology is also used here.

In addition, laser technology offers a broad array of marking methods that can be applied to nearly all materials for various purposes – from the numbering of components to decorating design elements.

Micro welding

As mentioned in the introduction, the first use of lasers in the watchmaking industry was in welding balance wheels, which regulate the timing of the mechanical watch mechanism. To this day, these devices are widely used – and laser welding is the industry standard. The superb focusability of laser beams is the key to the application’s success. Precise focusing is also advantageous in that the heat-affected zone is kept to a minimum, which reduces distortion.

The positioning of elements to be joined by this process poses a challenge with regard to the short process times. Here too, however, laser beams’ special attributes also have advantages: the massless beam makes non-contact processing possible, so that there is no physical impairment of the positioning of the weld elements.

Pulsed lasers with a high beam quality are particularly well-suited for laser beam micro welding – and one such laser is the TruPulse 21 from TRUMPF, with a wavelength of 1,064 nanometers, an adjustable pulse duration in the millisecond range, and a very high beam quality of 4 mm mrad. The pulsed operation of the laser makes it possible to momentarily attain comparatively high intensities, causing rapid fusing and welding without a greater amount of heat being conducted and leading to distortion.

Welding of highly reflective materials

Additionally, the higher intensities of pulsed lasers are helpful in welding highly reflective materials such as copper-based alloys. When it comes to welding with a continuous beam, single-mode fiber lasers in the TruFiber series are very especially suited due to their outstanding beam quality. To achieve the required degree of accuracy, this process usually uses triaxial machines with lateral accuracies (x/y) of approx. 5 micrometers. So the demands placed on the machine concept are just as high as the ones placed on the laser used.

In addition to joining watch springs, laser beam micro welding is used in the watchmaking industry to manufacture bezels, casings and metal watchbands, among other things. Here, the range of materials extends from various stainless steels and copper alloys (copper beryllium, brass) to gold.

Precision cutting with fiber lasers

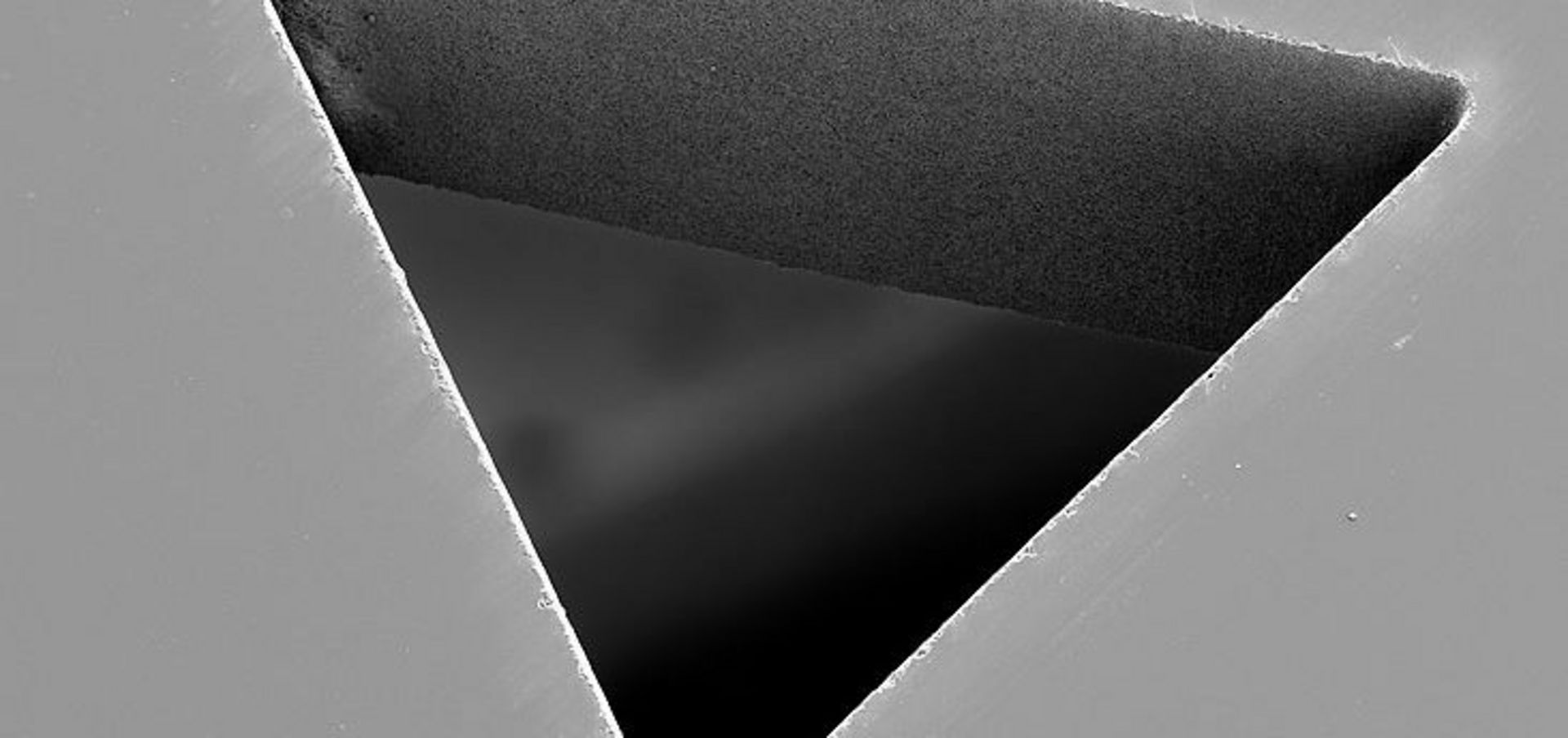

Along with welding, another major application area for laser technology is cutting. So it is no surprise that there are also a host of cutting applications for lasers in watchmaking. Of course, in watchmaking, where accuracy is so important, lasers are used solely for precision cutting, where they deliver maximum precision with minimum kerfs, while still maintaining the high quality of the cut edges.

Consequently, the industry tends to use fiber lasers – such as the machines in the TruFiber series. The key reason is the previously mentioned superb beam quality (M² < 1.1), which enables the best possible focusing of the beam. Fusion cutting is the cutting method employed, which sees the material melting into the kerf while shielded by an inert gas (nitrogen, argon) and the molten material then being forced out by the gas pressure.

Laser beam precision cutting is even more widely applied in the watchmaking industry than micro welding. Manufacturing of the various gears of watch mechanisms accounts for the lion’s share of this. Further cutting applications include making the hands, watch faces and diverse appliqués. The materials range from stainless steels to copper alloys and synthetic rubies, which are used for jewel bearings or as part of the pinion. In precision cutting, the required accuracies are even greater than in micro welding, namely about two micrometers at the working planes of the triaxial machines used.

Micromachining with ultrashort pulse lasers

Ultrashort pulse lasers, which have made great advancements in recent years and have come to dominate industrial applications, are especially suited to micromachining. Ultrashort laser pulses are defined as being those with intervals in the picosecond and femtosecond range. Pulses that are this short enable fundamentally different types of interaction between laser beam and material and thus expand the application area for laser technology.

Machining with longer pulses always constitutes a thermal process: depending on the intensity, the material is heated, melted, vaporized or directly sublimated, which – if the parameters have been chosen correctly – can be used for cutting, welding, etc. Due to the material’s conductivity, a heat-affected zone always forms – even if this usually quite limited, on account of the laser tool’s precision, and the result of the processing is generally not adversely affected.

With ultra-short laser pulses, however, the processing of the material is fundamentally different. The brief pulse intervals result in extremely high peak pulse power and, with appropriate focus, extreme power density on the workpiece of up to 1018 watts per square centimeter. By comparison, deep-penetration welding of steel plate requires approximately 106 watts per square centimeter.

Greater precision thanks to “cold” processing

Due to these extreme intensities, the material is practically instantly ionized and thus transformed to a plasma state. The plasma which is created is under extremely high pressure and thus expands away from the surface of the material, resulting in the ablation. The excess energy is thereby carried away in plasma or material vapor and through diffusion can spread out into the surrounding material in the form of heat.

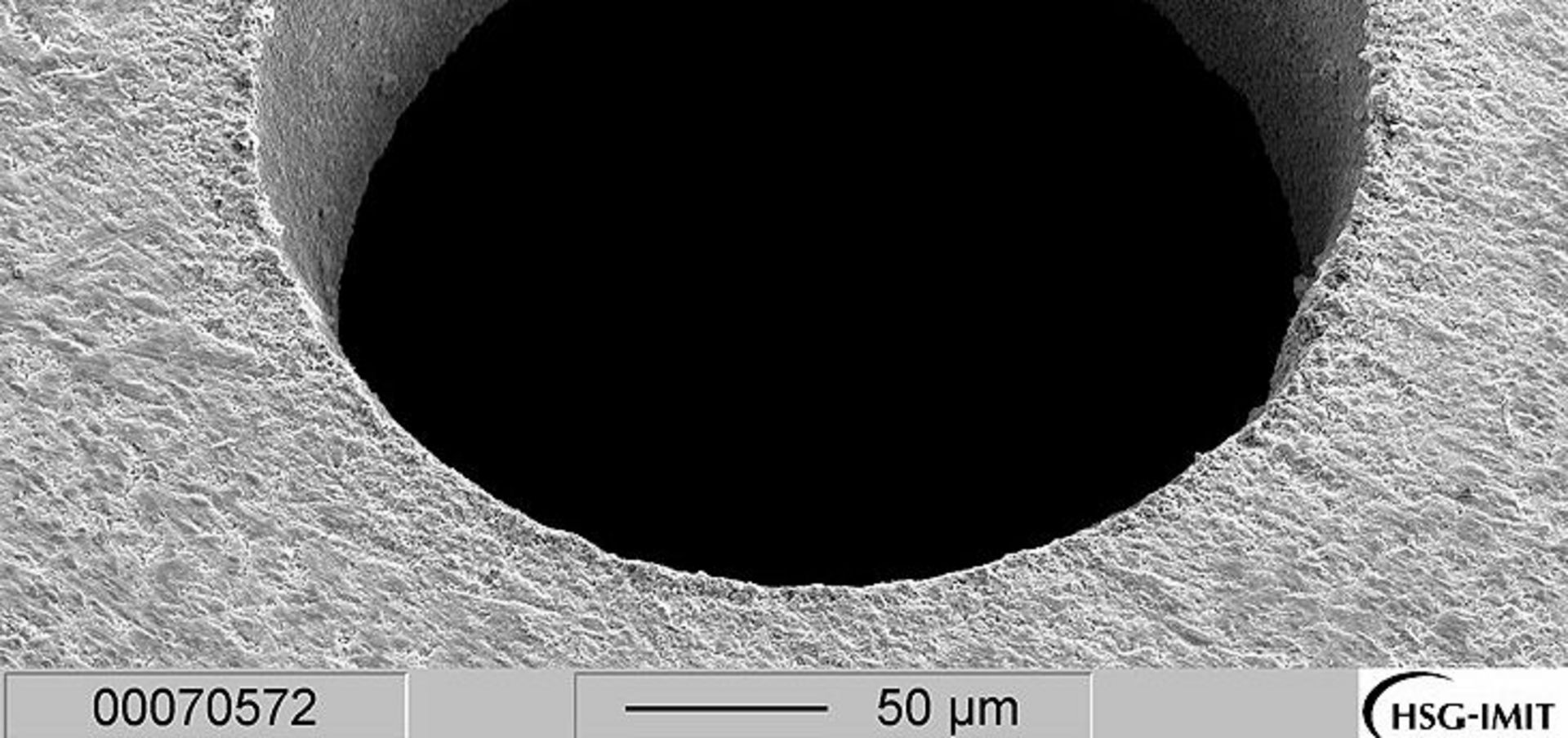

This consequently prevents, or at least substantially limits, the formation of a heat-affected area, ergo in conjunction with ultra-short laser pulses this is often referred to as “cold processing”. In this manner, with picosecond and femtosecond lasers it is possible to achieve an even higher degree of precision in cutting, drilling and ablation, although the process speeds are slower than is the case with nanosecond, microsecond or millisecond pulses.

Picosecond lasers in the watchmaking industry

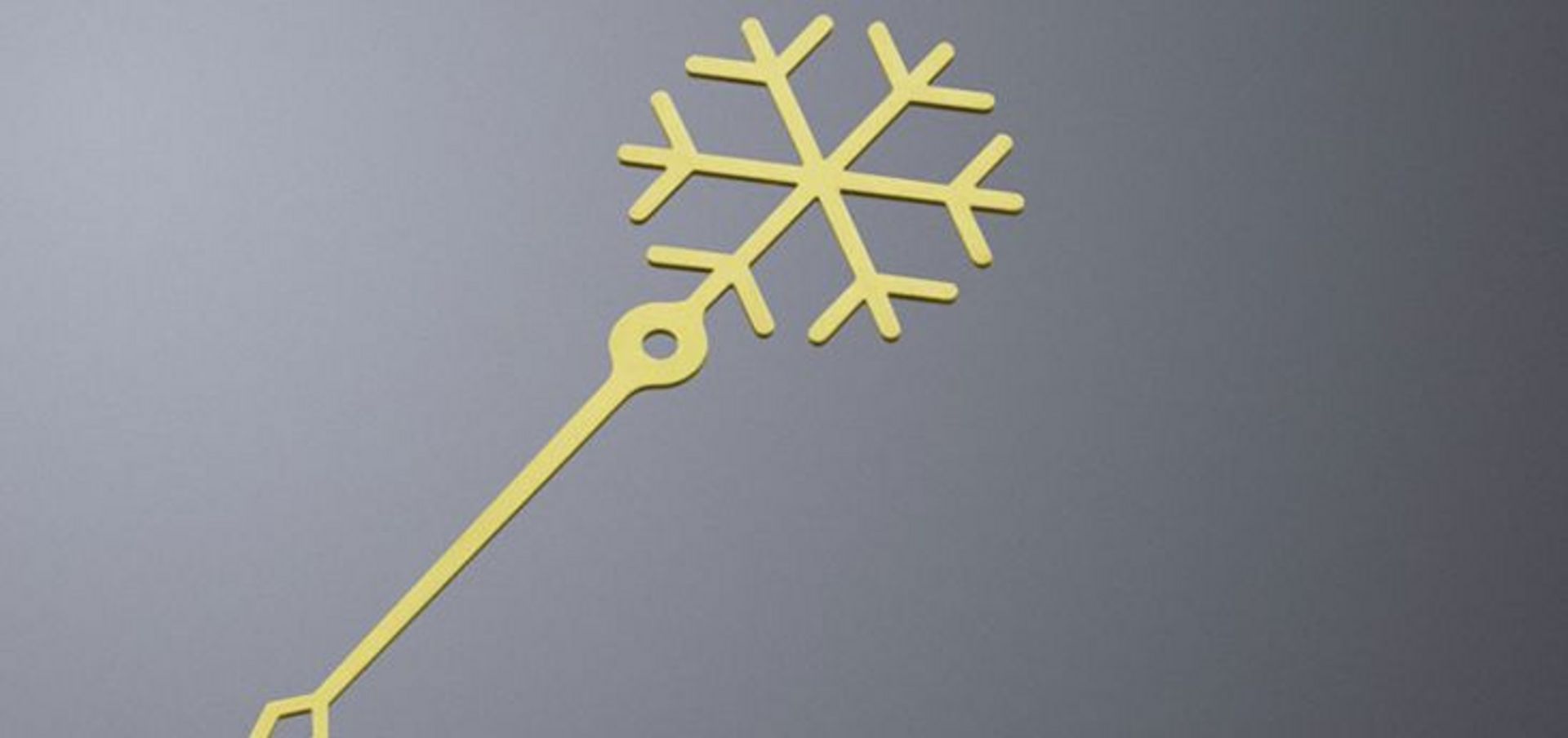

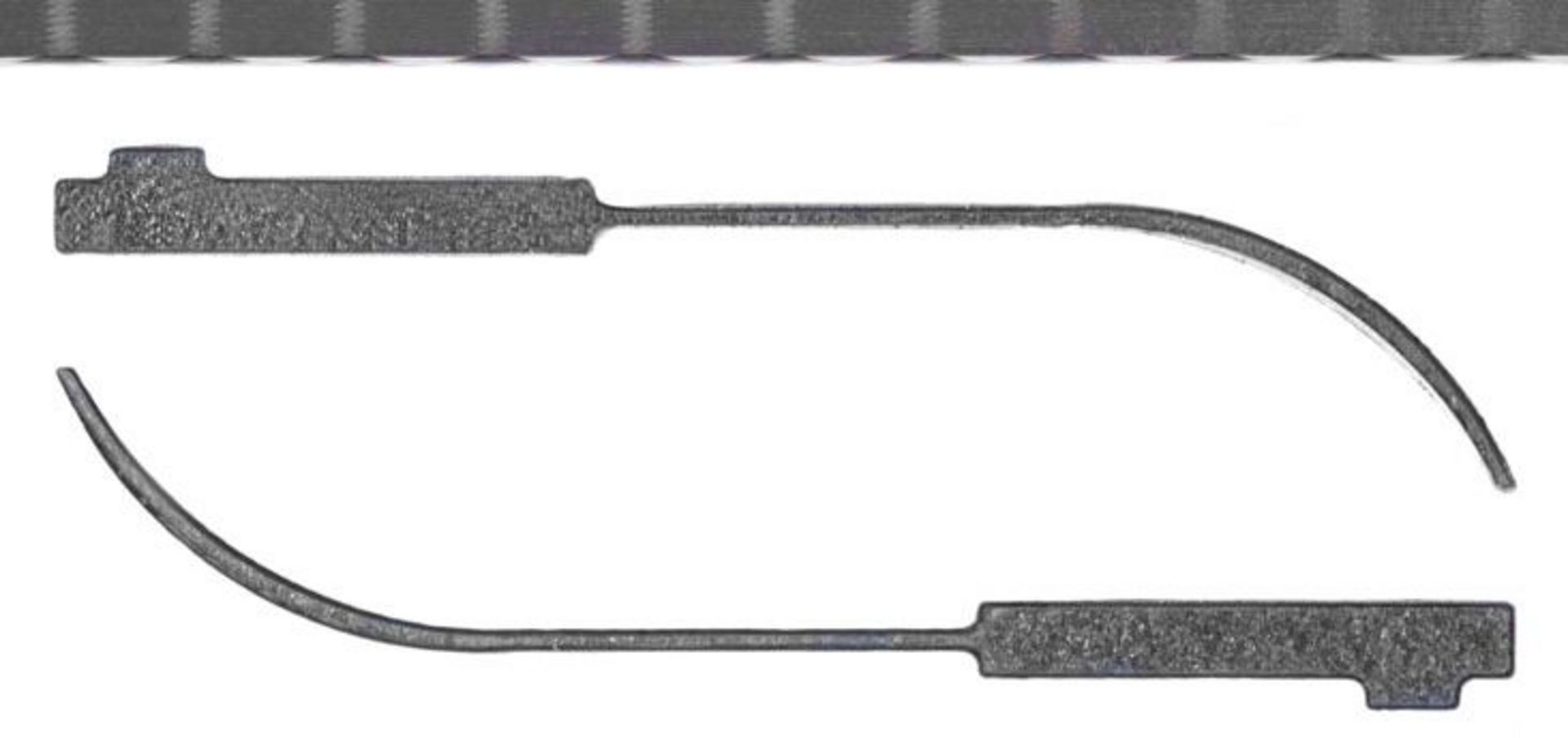

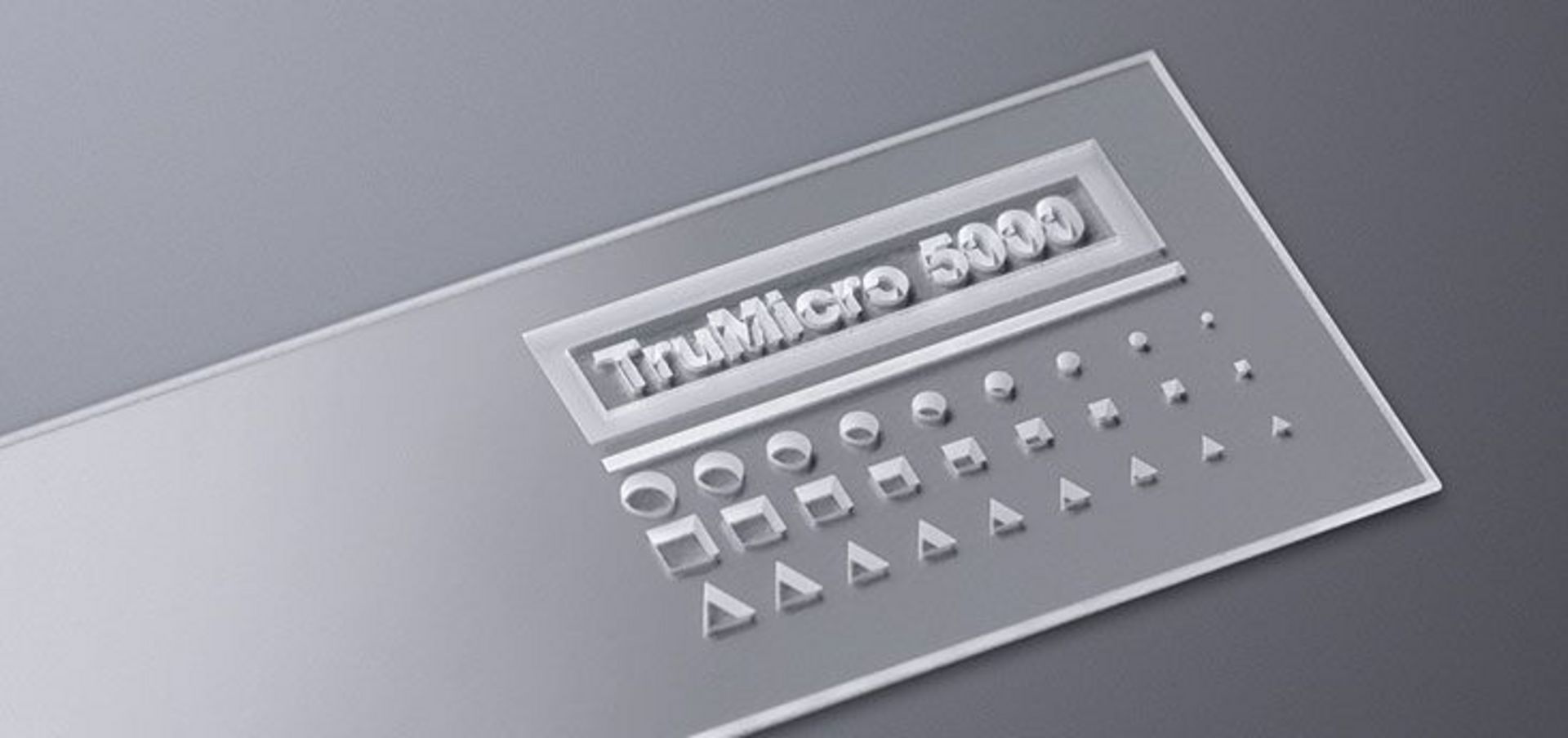

Meanwhile, of course, there are also numerous applications in the watchmaking industry where picosecond lasers can demonstrate their advantages. For example, some gears are already being cut with the aid of TruMicro Series 5000 lasers, which feature pulse durations of ten picoseconds, with the utmost in precision and no need for rework. A further application is the cutting of second-stop springs. These springs are made of steel sheet that is only 0.01 to 0.05 millimeters thick, yet is cut without the slightest distortion.

In addition to the previously mentioned increase in precision, ultrashort laser pulses also make it possible to process materials that longer laser pulses are barely able to process, if at all. These materials are primarily those that are very hard and brittle, those that cannot be processed under stress, and also transparent or thermo-sensitive materials, which are unsuitable for processing with lasers using longer pulses.

Pawls are an example of this: their pinion and pinion wheel must avoid steel, because of its magnetic properties, and instead be made of silicon. These intricate, weight-saving designs cannot be manufactured with the same accuracy by any other means.

Processing ceramics and sapphire

In addition to steel and precious metals, bezels – or even entire watch casings – are being made of ceramics. These have the advantage of being extremely hard, so that they are barely susceptible to dents and scratches. Drilling or the application of surface structures by ablation are once again applications for which ultrashort laser pulses are ideal.

Moreover, not only can watch crystals and watch faces made of sapphire glass be cut and drilled, they can also be marked on the interior using picosecond lasers. Rated at nine on the Mohs scale of mineral hardness, sapphires are the second hardest (surpassed only by diamonds) transparent material and thus offer enormous resistance to scratches. However, they can hardly be mechanically processed at all.

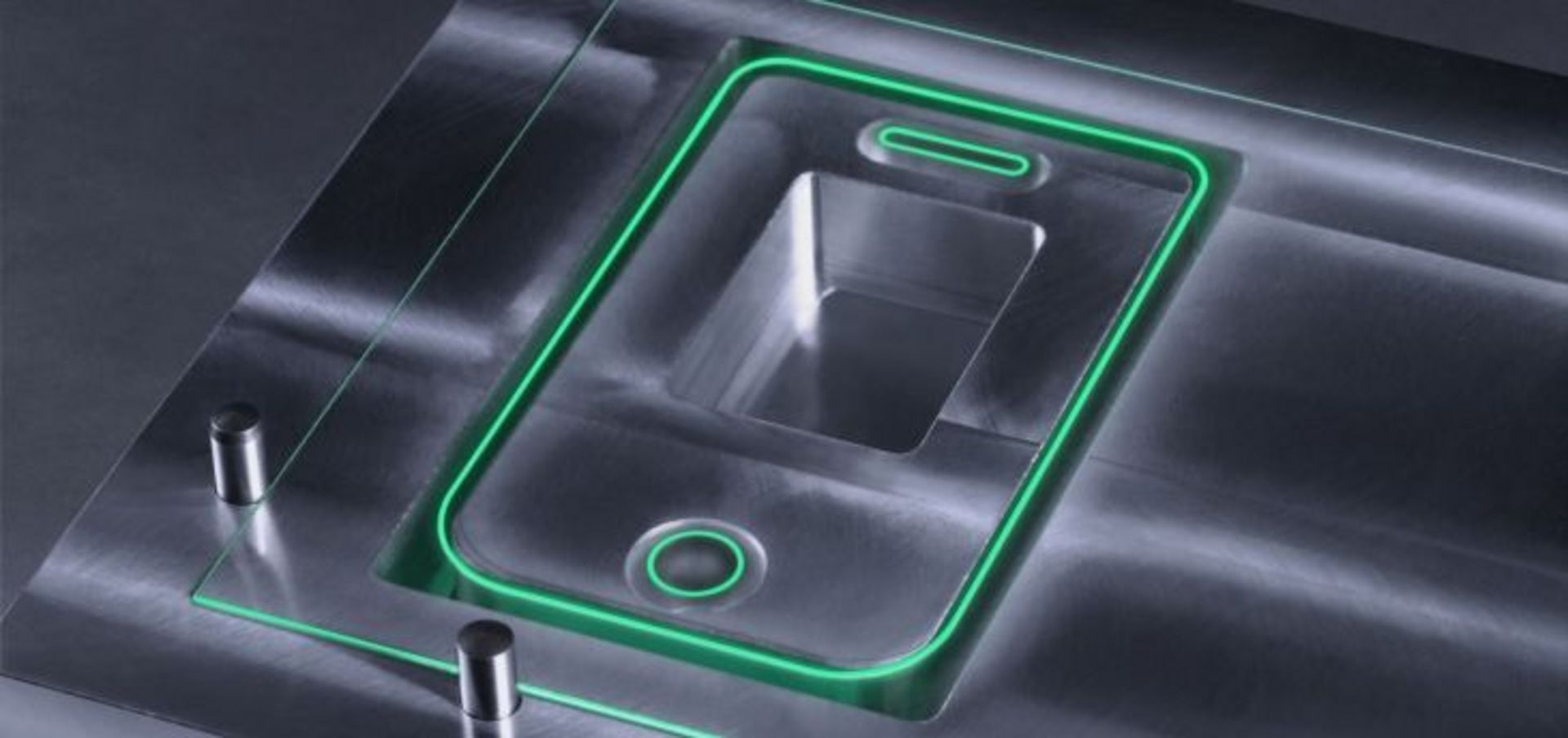

Chemically prestressed glasses are currently enjoying growing popularity; above all they are used in tablet computers and smartphones, but also for watch crystals – once again because of their hardness and scratch resistance. Here as well, the glass plates are cut precisely and cost-effectively with picosecond lasers.

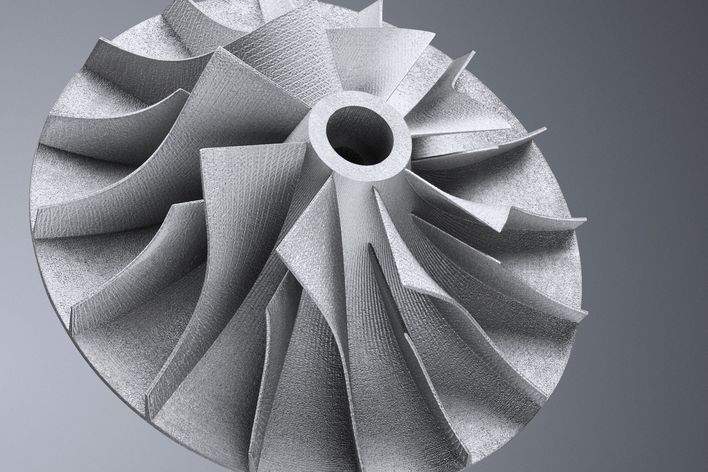

Parts produced by means of additive laser melting

Another laser-based manufacturing process that could catch the eye of the watchmaking industry is additive manufacturing by means of laser melting. In this process a component is built up successively in layers from a powder foundation; the powder is selectively melted by a focused laser beam and fuses together. This process offers almost limitless design possibilities, as it allows complex, three-dimensional structures – including slots and concealed cavities – to be manufactured.

Compared with casting and subtractive processes, additive manufacturing is usually slower, though, and therefore of only limited suitability for mass production. But as products are produced in more and more variety, driven by the broad trend of increasing product customization, additive manufacturing soon becomes economically viable. Especially in the watchmaking industry, much of which is dedicated to producing luxury goods, this trend opens up enormous potential for limited series or even one-of-a-kind production.

Laser-based additive manufacturing is the ideal technology for this and could potentially bring about a sea change in the watch and jewelry industry.