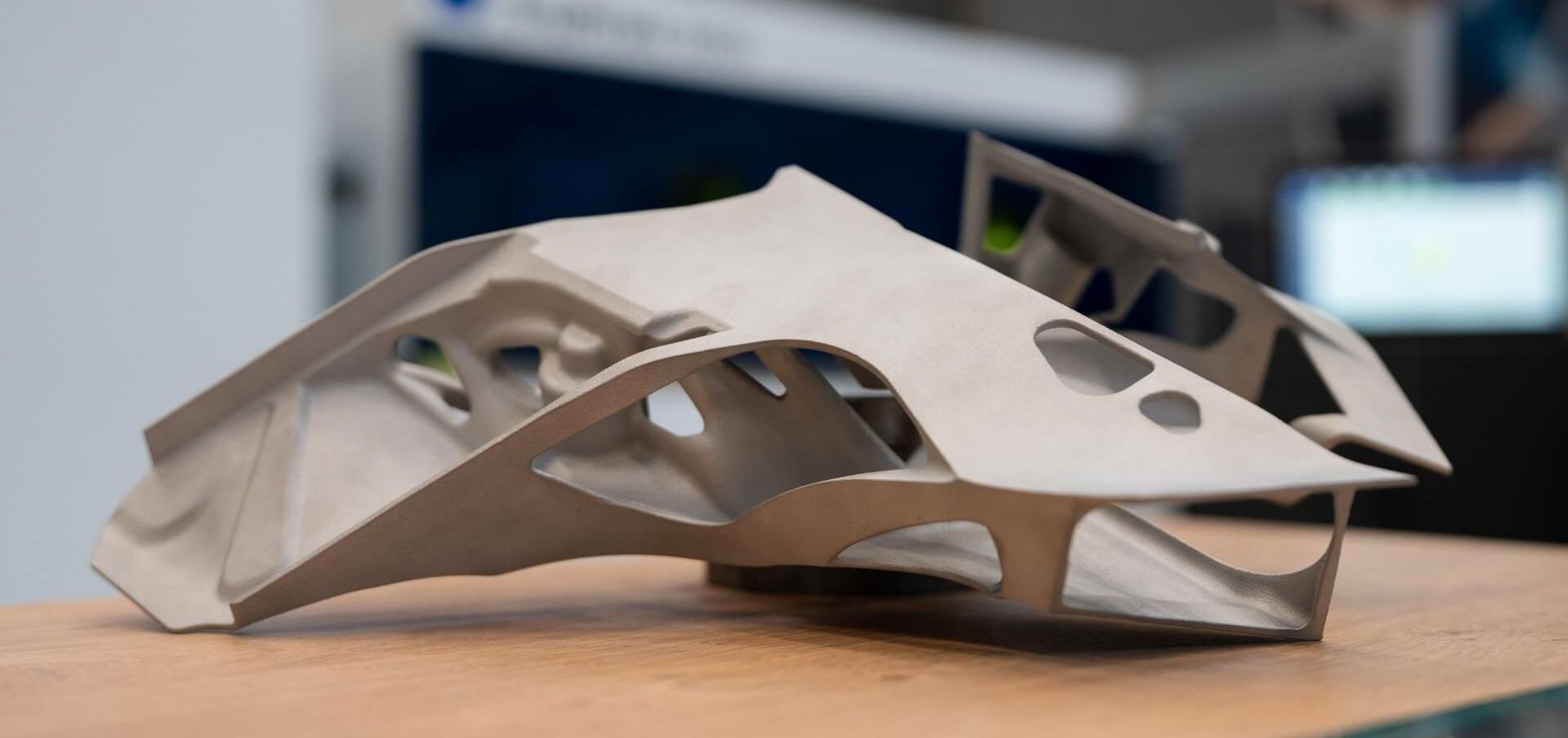

Mr Spiegelhalder, the TruPrint Series 3000 has recently had a new addition. Customers can now choose between the TruPrint 3000 with 500-watt lasers and the more powerful variant with 700-watt lasers. From the customer's point of view, what is the advantage of the higher power levels?

Spiegelhalder: That has to be the productivity, hands down. The TruPrint 3000 with 700 watts is significantly faster. We are accelerating the part build time by a factor of 1.4. This means less time per part. Output is increased by more than a third, and the cost per part is drastically reduced. In some cases, it is even better to use just one 700-watt machine than two with 500 watts each. This saves a lot of space and personnel. Theses are strong arguments at a time when the cycle rate is constantly increasing in the automotive industry, medical technology or in 3D printing services.

More power means higher temperatures, right? Does this mean you need different powders?

Spiegelhalder: All powders used in 500-watt laser printers can also be processed in 700-watt machines without difficulty. Sometimes they can be processed even more productively: for example, materials such as aluminum cast alloy or high-strength titanium alloys. Furthermore, there are now powders on the market that cope particularly well with the high power levels and enable even faster build rates and better part quality than standard powders, for example, Equispheres' AlSi10Mg aluminum powder.

Is it possible for the user to operate more slowly as well – in other words, to print at lower power levels? Or to phrase the question differently: can the machine with 700 watts cope with the parameters of a 500-watt machine?

Spiegelhalder: Yes, of course, no problem. The TruPrint 3000 with 700 watts is downward compatible.

On the other hand, is it possible for the user to "speed up", in other words, accelerate the part build time by a higher factor than 1.4?

Spiegelhalder: Yes, in principle. The decisive factor is the part density and the associated mechanical strength to be achieved.

In this case, do we still need the TruPrint 3000 with 500-watt lasers?

Spiegelhalder: Yes, of course! The variant with 500 watts is still the right machine for certain applications. The TruPrint 3000 with 500-watt lasers can still be the perfect solution when speed does not play a major role, the processed materials do not need the increased power and when the printer capacity is fully sufficient in the long term.

What do you advise a customer who is unsure whether they should choose the 500-watt or 700-watt variant?

Spiegelhalder: You need to ask very basic questions when making an investment decision. Most importantly: what does the machine cost per part? But also: is it possible that I will have to produce more parts in future than I am aware of at the moment? How variable does my production have to be? Am I at risk of losing orders due to a lack of speed? Anyone unsure of the answers at this point should choose the higher power solution. And whenever flexibility and greater material variety are also important, I would also recommend selecting the TruPrint 3000 with 700 watts. True, it costs a little more than the smaller variant – but is much cheaper than another laser.

While we are on the subject - let's talk about money, Mr. Spiegelhalder. How much more does the extra power cost the customer?

Spiegelhalder: Good point - we are talking about a price difference of around 3.5 percent. If you compare the relatively small price difference with an productivity increase of almost 30 percent, then the TruPrint 3000 with 700 watts is the most economical machine for many applications.

Can you summarize the three top arguments for the TruPrint 3000 with the higher power level of 700 watts, Mr. Spiegelhalder?

Spiegelhalder: The TruPrint 3000 with 700-watt lasers is fast. It is extremely flexible. And it makes outstanding economic sense in terms of cost per part.

One more question - apart from powerful lasers, are you also a fan of Newton meters in engines?

Spiegelhalder: Yes, of course. I am very interested in engine technology. In both cars and airplanes.