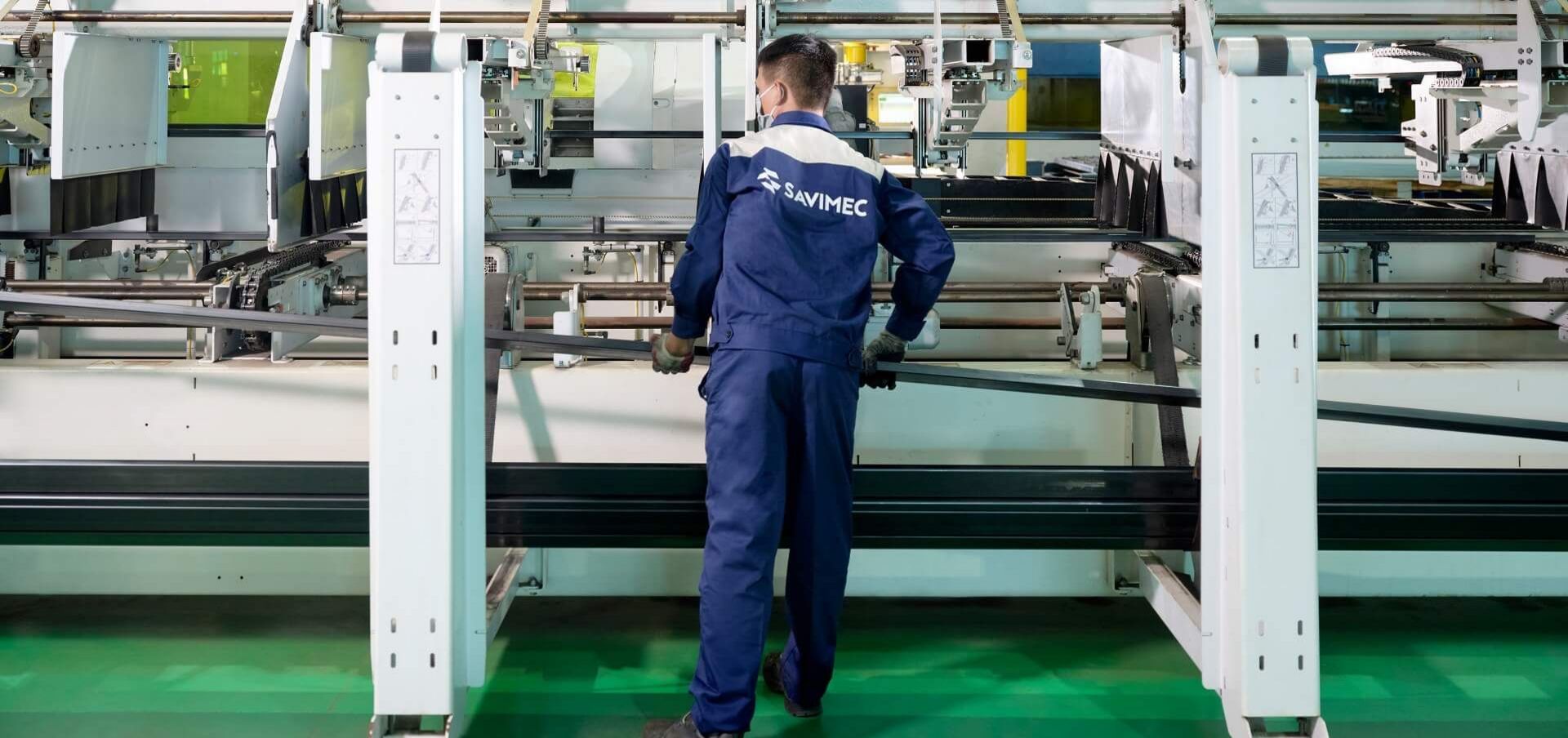

Ngo Sach Vinh has always been fascinated by technology. So it made sense for him at the age of 24 to undergo training in telecommunications. He completed his training and initially repaired mobile phone displays. But it didn’t stop there. Vinh founded a sheet metal processing company in 2009 and specialized in the production of electrical cabinets for the telecommunications and electrical industry. He quickly recognized the potential in metal processing and founded Sao Viet Technology Mechanical Joint Stock Company, SAVIMEC, in 2015. Ngo Sach Vinh focused on expanding the company’s portfolio and the expertise of his employees, quickly becoming one of the leading sheet metal processing providers in Vietnam. In 2017, he set a milestone in SAVIMEC’s development with the construction of a 12,000 square meter production hall in the middle of the important economic triangle of Hanoi, Quang Ninh and Hai Phong.

Investing in the future

It might sound simple in retrospect, but in fact it was hard work requiring a lot of courage, because Ngo Sach Vinh has never taken half measures: "To set myself apart from the competition, I focused on modern technologies right from the start. I wanted to be able to deliver exceptional products of perfect quality, and this was achieved by investing in highly productive machines, among other things.” In Vietnam this is not a matter of course. Newcomers to sheet metal processing often start with used machines. But that is not an option for Vinh: With the purchase of a TruPunch 2000 and a TruBend 5085 from TRUMPF in 2018, he laid the foundation for a fleet of machines with which he hopes to achieve his ambitious goal: SAVIMEC is to become a globally competitive, highly automated Smart Factory.

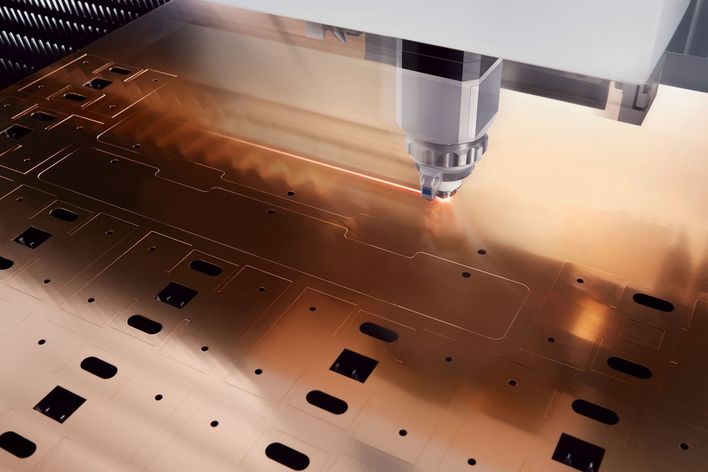

Today, SAVIMEC has ten TRUMPF machines in its production department. These include the fully automated TruBend Center 7030 and TruBend 7036 bending machines, as well as the highly productive TruLaser 5030 fiber 2D laser cutting machine. The company offers all services in the sheet metal process chain – from design to powder coating and manufactures complex parts and components from steel, stainless steel and aluminum in two-shift operation. Customers come from various industries, including the automotive, air conditioning, telecommunications and electronics sectors. “Compared to many of our competitors, we impress customers with our know-how, very high quality standards and modern technologies,” explains Vinh proudly.

Full steam ahead to ensure success

Laser tube cutting has also been part of the SAVIMEC portfolio since 2021. “Only very few job shops in Vietnam can offer this service, but customers are now increasingly requesting this technology,” says Ngo Sach Vinh. “We are meeting this demand with our new TruLaser Tube 5000 fiber. The machine offers everything that is important to us: speed, accuracy and quality."

The TruLaser Tube 5000 fiber at SAVIMEC is equipped with the RapidCut option and therefore enables particularly high feed rates. “This significantly increases our productivity, especially with thinner wall thicknesses,” says Vinh happily and adds, "No other machine can keep up." Because SAVIMEC also deals with a large processing spectrum as well as different tube geometries, Vinh wanted a machine requiring little setup effort. “We process rectangular, round and oval tubes with different diameters. The setup-free self-centering collet chuck automatically ensures that the tubes are correctly clamped into the machine. This saves time and gives us the high processing accuracy that our customers expect,” explains Ngo Sach Vinh. In addition to bevel cuts of up to 45 degrees, the TruLaser Tube 5000 fiber can also create threads fully automatically. “This also increases our productivity because it eliminates manual processing steps, which are also prone to errors,” says Vinh. The TruLaser Tube 5000 fiber is automatically loaded with the LoadMaster Tube loading unit, speeding up the processes as well. “All in all, the system fits perfectly into our concept,” explains the head of SAVIMEC. “Not only can we meet the requirements of our existing customers quickly and to the best quality standards, but we have also gained new customers through this expansion of our portfolio.”

Quality pays off

Commitment, innovative thinking and the courage to make investments are part of Ngo Sach Vinh’s recipe for success: “Machines from TRUMPF offer the quality and productivity that my company needs to grow even more. And it is doing precisely that: Since 2021, SAVIMEC has not only been successful in the Vietnamese market, but has also been exporting into the USA and some European countries. The entrepreneur is not content with this success alone. His production processes are already synchronized and many production steps run automatically. He wants to continue working on this. “I want SAVIMEC to become Vietnam’s largest job shop as well as an internationally competitive company,” he clarifies. A glance at what he has already achieved shows that he can do it.