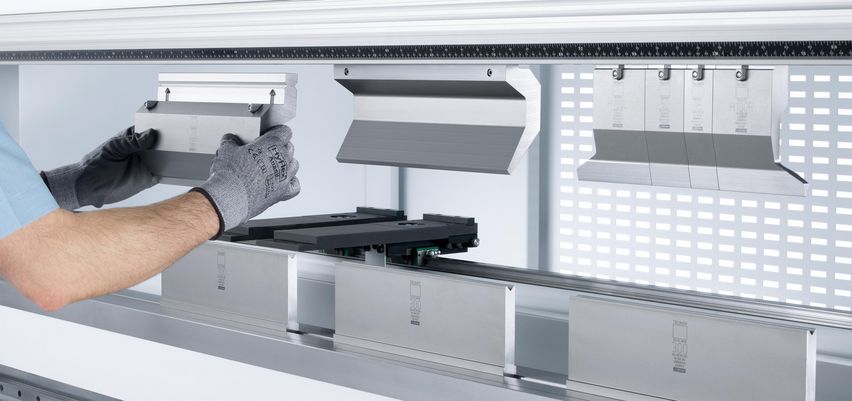

Set up tools simply from below due to the Safety Click.

Cost-effective standard machine

The TruBend Series 3000 brings together the best TRUMPF quality with simple operation and an attractive price-performance ratio. This means you can manufacture economically even in low utilization, and profit from precise results as well as the highest safety standards. Through the perfect interaction of all components, the TruBend Series 3000 machines are the fastest bending machines in their class.

For complete clamping tool flexibility, choose between different system options.

Due to the closed frame, you can use the entire bending length without restrictions.

The backgauge positions blanks precisely. You can select a 2, 4, or 5 axis backgauge.

With the ACB Laser angle measuring system, even the first part is a success.

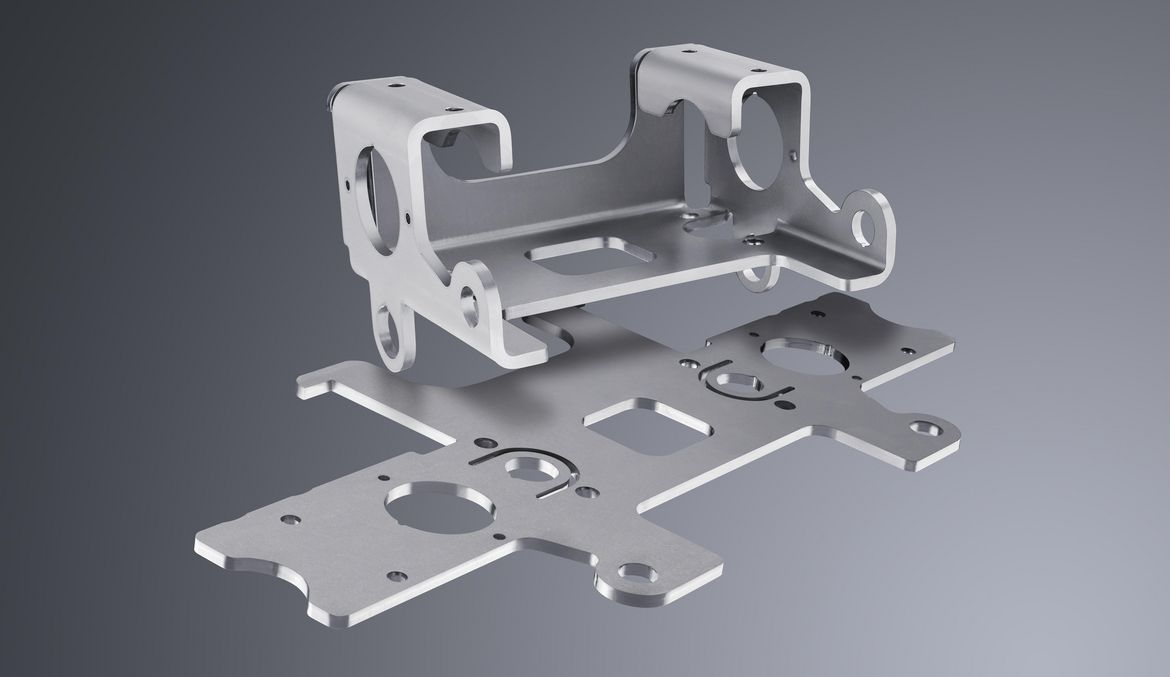

Component with different bends

The TruBend bending machines are so flexible that you can use them to solve the widest variety of tasks.

Long profiles

Produce long profiles with the machines from the TruBend Series 3000.

The highest level of flexibility in different sheet thicknesses

Process parts with a wide variety of sheet thicknesses on the TruBend Series 3000 machines.

|

TruBend 3066

|

TruBend 3100

|

TruBend 3170

|

|

|---|---|---|---|

| Press force | 660 kN | 1000 kN | 1700 kN |

| Bending length | 2040 mm | 3060 mm | 4080 mm |

| Width between columns | 2364 mm | 3384 mm | 4404 mm |

| User interface | T3500T multi-touch control | T3500T multi-touch control | T3500T multi-touch control |

| Maximum speed Y axis, rapid downward movement | 200 mm/s | - | - |

| Maximum speed Y axis, operation | 15 mm/s | 15 mm/s | 15 mm/s |

| Dimensions, weights | |||

| Length | 2587 mm | 3607 mm | 4647 mm |

| Width | 1644 mm | 1644 mm | 1644 mm |

| Height | 2370 mm | 2370 mm | 2925 mm |

| Weight | 5650 kg | 7700 kg | 15000 kg |

| Weight for enlarged version (option) | - | 8300 kg | - |

The technical data of all product versions as a download.

Numerous functions make working with the TruBend Series 3000 even safer, easier, more ergonomic, and more productive.

The manual ACB Laser angle measuring system is a non-contact, optical system for angle measurement. A laser projects a line onto the sheet; a camera detects the angle. To do this, the front measuring unit is manually moved to the right place; the rear measuring unit automatically moves with it.

Support brackets with variable height adjustment make component handling easier. The robust support brackets have a high load capacity.

You can call up programs quite easily using the bar code reader.

The 5-axis backgauge offers a high degree of bending flexibility through angled bends.

TruTops Boost

Program your bending machines intelligently using TruTops Boost, the all-in-one solution for 3D design. Numerous automated processes save you time-consuming routine processes. You also profit from a comprehensive ruleset with the bundled technical expertise of TRUMPF.

TecZone Bend

Program faster than ever before: With TecZone Bend you can combine bend programming in the office with shop floor programming at the TruBend bending machine. A program suggestion is automatically created in a few seconds based on 2D and 3D data – including NC program.

Software

The software portfolio from TRUMPF optimises your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customised Industry 4.0 solutions for your Smart Factory.

You can choose between more than 150 upper and lower tool types for your personal range. You can order tools individually or as a set.

For tools up to 12 inches long, lightweight tools with a weight saving of more than 30% are equipped with the Safety-Click as standard. This reduces the setup time and relieves the strain on the operator.

During the processing of galvanized sheets, even after just a few bends, there may be zinc deposits on the die, resulting in cold welding. This causes imprints on the component and imprecision. This can be avoided with the coated LASERdur ZN TRUMPF bending tools. They combine a high level of surface hardness with excellent sliding properties, are corrosion-resistant, and do not need to be cleaned.

For specific requirements, TRUMPF will develop your own personal tool solution. To guarantee the quality of your parts, we test the tools in advance with your specific material and create initial sample parts.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.