Erweitern Sie die programmierbaren Fokussieroptiken von TRUMPF um Optionen für die Bildverarbeitung. Die PFO ist in der Lage Geometrien auf der Werkstückoberfläche zu erkennen und passt den Laserprozess an die individuelle Bearbeitungssituation an.

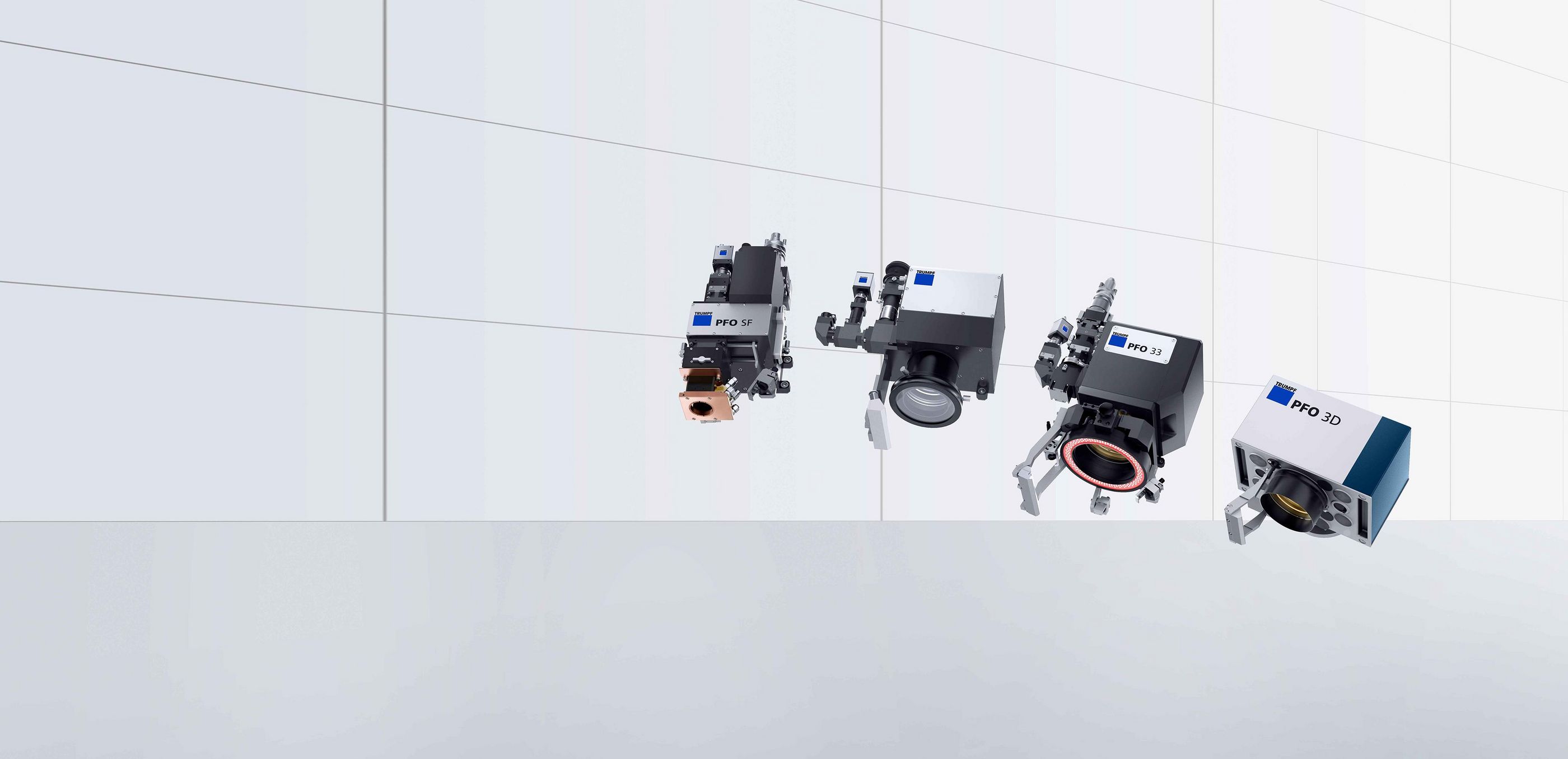

Die TRUMPF Optiken für die Remotebearbeitung

Die programmierbaren Fokussieroptiken der Reihe PFO sind Scanneroptiken zum Remoteschweißen- und schneiden. Mit Hilfe von zwei Spiegeln kann der Laserstrahl an jede vorgegebene Position innerhalb des Bearbeitungsfeldes oder -raumes positioniert oder auf beliebigen Nahtgeometrien geführt werden. Diese können damit geschweißt werden, ohne dass sich das Werkstück oder die Fokussieroptik bewegen. Zusätzlich wird kein Schutz-/ Prozessgas benötigt.

Modernste digital angesteuerte Antriebe sorgen für Tempo.

Roboter, Laser und PFO werden in Echtzeit synchronisiert und exakt positioniert.

Im PFO-Portfolio finden Sie eine Lösung für jede Anwendung - vom Low- bis High-Power-Bereich.

Erhöhte Prozesssicherheit und Qualität durch optionale Anbindung intelligenter Sensoriklösungen.

Laserschweiß- und Schneidprogramme mit der PFO SmartTeach App intuitiv, mobil und schnell einrichten.

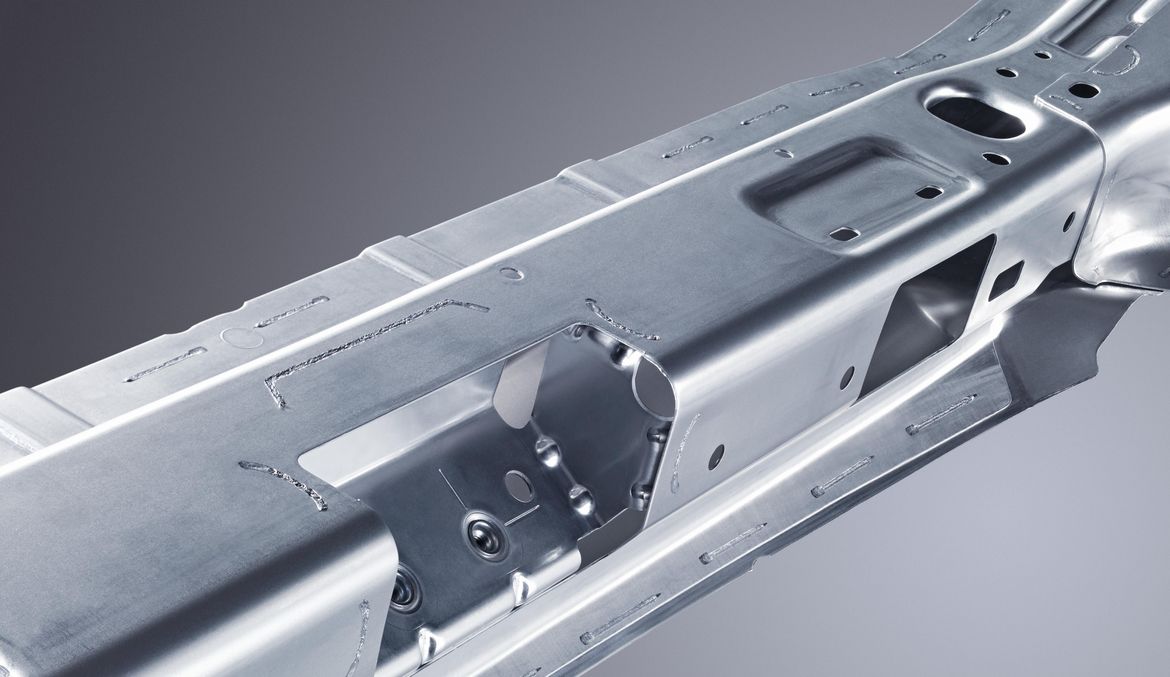

Autotür

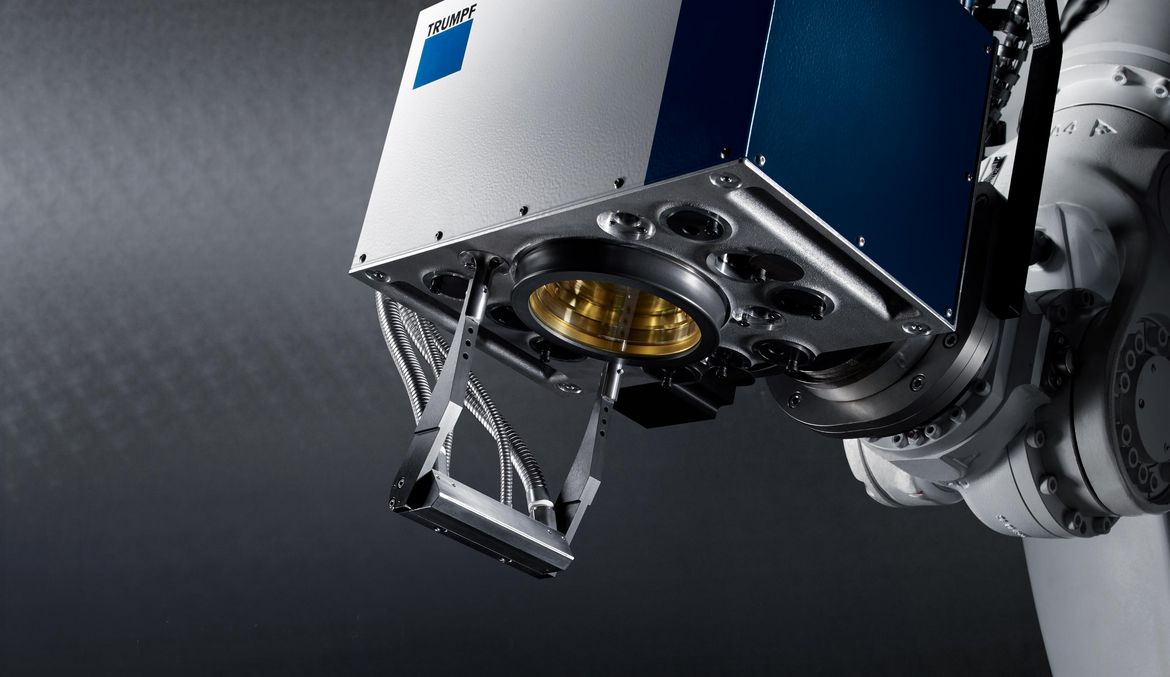

Die programmierbaren Fokussieroptiken (PFO) von TRUMPF eignen sich insbesondere für die schnelle und zuverlässige Bearbeitung von großen Werkstücken. Die Kombination aus Roboter und PFO vereint das Beste aus beiden Welten: einen großen Arbeitsraum mit hoher Dynamik und Präzision sowie eine lange Brennweite, die große Arbeitsabstände zum Werkstück erlaubt.

Scannerschweißen einer Autotür

Mit Hilfe von zwei Spiegeln kann der Laserstrahl an jede vorgegebene Position innerhalb des Bearbeitungsfeldes oder -raumes positioniert werden oder führt den Laserstrahl auf beliebigen Konturen. Da sich dabei weder das Werkstück noch die Optik bewegen müssen, ermöglicht die PFO eine hohe Produktivität bei gleichzeitig geringen Bearbeitungskosten und zuverlässigen Prozessergebnissen. Über eine spezielle Steuereinheit lassen sich sogar "fliegende" Bearbeitungen realisieren (Welding on the fly).

Heckmittelstück einer Automobilkarosserie

Hohe Präzision und Wiederholgenauigkeit über einen großen Arbeitsbereich – das robotergeführte Scannerschweißen führt bei großen Werkstücken zu immensen Produktivitätssteigerungen.

Scannerschweißen mit PFO 3D

Die Spiegel in der programmierbaren Fokussieroptik PFO 3D arbeiten hochdynamisch. Die schnelle Strahlablenkung verkürzt die Bearbeitungs- und Zustellzeit erheblich.

Lasergeschweißte Kunststoffteile

Mit den programmierbaren Fokussieroptiken von TRUMPF können nicht nur metallische Werkstoffe geschweißt werden, sondern auch Kunststoffe. Die Optik PFO 20 ist optimal für das Laser-Kunststoffschweißen ausgelegt und erzeugt dichte und ästhetische Schweißnähte.

Batteriegehäuse

|

PFO 14

Produkt vergleichen

|

PFO 20

Produkt vergleichen

|

PFO 33

Produkt vergleichen

|

PFO 1D

Produkt vergleichen

|

PFO 3D

Produkt vergleichen

|

PFO SF

Produkt vergleichen

|

|

|---|---|---|---|---|---|---|

| Laserparameter | ||||||

| Wellenlängenbereich | 930 nm - 1030 nm 2 |

930 nm - 1085 nm

2 515 nm |

515 / 930 nm - 1085 nm | 930 nm - 1030 nm 2 | 1030 nm 2 | 1030 / 1075 nm |

| Leistung | bis 2000 W (cw) | bis 2000 W (cw) | bis 12000 W (cw) | bis 8000 W (cw) | bis 8000 W (cw) |

PFO SF20: bis 8000 W (cw)

PFO SF33: bis 12000 W (cw) |

| Numerische Apertur | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 |

| Typ Laserlichtkabel | LLK-D, LLK-B, LLK-A | LLK-D, LLK-B, LLK-A | LLK-D | LLK-D, LLK-B | LLK-D | LLK-D |

| Optikkonfiguration 1 | ||||||

| Kollimation | 35 / 56 mm | 35 / 56 / 80 / 90 / 100 mm |

140 mm (TruDisk & TruFiber Multi Mode)

150 / 200 / 300 mm (TruFiber Single Mode) |

150 mm | 138 mm |

PFO SF20: 90 mm (TruDisk, TruMicro 7000, TruFiber Multi Mode)

PFO SF20: 150 / 200 mm (TruFiber Single Mode) PFO SF33: 140 mm (TruDisk, TruMicro 7000, TruFiber Multi Mode) |

| Brennweite | 100 / 160 / 163 / 254 / 330 / 420 mm | 90 / 100 / 135 / 160 / 163 / 200 / 254 / 264 / 280 / 330 / 395 / 420 / 560 / 740 mm |

255 / 345 / 450 mm (Standard)

160 / 265 / 345 / 450 / 600 mm (HighBrightness) |

150 / 200 / 300 mm | 255 / 345 / 450 / 600 / 900 mm | 200 / 300 / 400 / 500 / 600 mm |

| z-Hub bei Objektivbrennweite | - | - | - | - |

f255: ± 22 mm

f345: ± 40 mm f450: ± 70 mm f600: ± 100 mm f900: ± 220 mm |

- |

| Feldgröße (Ellipse Y x X) bei Objektivbrennweite |

f100: 47 mm x 18 mm

f160: 110 mm x 75 mm f163: 110 mm x 70 mm f254: 170 mm x 120 mm f330: 220 mm x 178 mm f420: 286 mm x 230 mm |

f100: 50 mm x 36 mm

f135: 70 mm x 50 mm f160: 86 mm x 66 mm f264: 180 mm x 136 mm |

- | - |

f255: 174 mm x 102 mm (z=0)

f345: 240 mm x 140 mm (z=0) f450: 320 mm x 190 mm (z=0) f600: 376 mm x 230 mm (z=0) f900: 525 mm x 340 mm (z=0) |

f200: 11 mm x 17 mm

f300: 17 mm x 25 mm f400: 22 mm x 34 mm f500: 28 mm x 42 mm f600: 28 mm x 42 mm |

| Feldgröße (Ellipse Y x X) bei Objektivbrennweite für TruDisk/TruMicro | - | - |

f255: 180 mm x 112 mm

f345: 244 mm x 150 mm f450: 320 mm x 196 mm |

- | - | - |

| Feldgröße (Ellipse Y x X) bei Objektivbrennweite für HighBrightness Objektive | - | - |

f160: 80 mm x 57 mm

f265: 140 mm x 102 mm f345: 208 mm x 152 mm f450: 306 mm x 208 mm f600: 388 mm x 257 mm |

- | - | - |

| Feldgröße (Ellipse Y x X) bei Objektivbrennweite für TruFiber | - | - |

f265: 140 mm x 102 mm

f345: 208 mm x 152 mm f450: 306 mm x 208 mm f600: 388 mm x 257 mm |

- | - | - |

| Feldgröße (Ellipse Y x X) bei Objektivbrennweite für TruDisk 515 nm | - | - |

f160: 77 mm x 56 mm

f265: 140 mm x 102 mm f345: 202 mm x 144 mm f450: 312 mm x 190 mm |

- | - | - |

| Bauform | ||||||

| Abmessungen (B x H x T) | 278 mm x 391 mm x 202 mm (Beispielkonfiguration mit fc56 und f160) | 278 mm x 296 mm x 202 mm (Beispielkonfiguration mit fc90 und f264) | 336 mm x 340 mm x 227 mm (Beispielkonfiguration mit fc140 und f450) | 227 mm x 562 mm x 229 mm | 412 mm x 266 mm x 366 mm |

223 mm x 200 mm x 198 mm (Scannerkopf ohne Objektiv)

120 mm x 195 mm x 252 mm (PFO Steuereinheit) |

| Gewicht | 15 kg | 15 kg |

< 35 kg

< 38 kg mit OCT-Scanner |

12,5 kg | 35 kg |

13 kg (Scannerkopf)

4 kg (PFO Steuereinheit) |

| Kompatibilität | ||||||

| Verfügbare Laser | TruDiode, TruDisk, TruMicro | TruDiode, TruDisk, TruFiber, TruMicro, TruPulse | TruDisk, TruFiber, TruMicro | TruDiode, TruDisk | TruDisk |

PFO SF20: TruDisk, TruMicro 7000, TruFiber Multi Mode, TruFiber Single Mode

PFO SF33: TruDisk, TruMicro 7000, TruFiber Multi Mode |

| Verfügbare Sensorik | - | VisionLine, CalibrationLine, Temperaturregelung zum Kunststoffschweißen und zum Härten | VisionLine Cam/Basic/Detect, VisionLine OCT Detect, CalibrationLine | - | VisionLine, CalibrationLine, SeamLine Remote, OCT Nahtlageregelung | VisionLine Cam/Basic/Detect, CalibrationLine |

| Optionen | ||||||

| Verfügbare Optionen | Crossjet, Kamerabeobachtung | Crossjet, Sensorikschnittstelle, Beleuchtung | Crossjet, MDE-Düse, Schmauchglocke, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Schutzglasüberwachung | Crossjet, MDE-Düse, Schutzgaszufuhr, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Kassettenmodul, Schutzglasüberwachung | Ausführung als I-PFO, Crossjet, MDE-Düse, Schmauchglocke, Beleuchtung | Crossjet, MDE-Düse, verschiedene Schutzgasdüsen, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Schutzglasüberwachung, Kühlwasserüberwachung |

| Verfügbare Software-Optionen | TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App, Real-time contour check | - | TruTops I-PFO und TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App, Real-time contour check |

|

PFO 14

|

PFO 20

|

PFO 33

|

PFO 1D

|

PFO 3D

|

PFO SF

|

|

|---|---|---|---|---|---|---|

| Laserparameter | ||||||

| Wellenlängenbereich | 930 nm - 1030 nm 2 |

930 nm - 1085 nm

2 515 nm |

515 / 930 nm - 1085 nm | 930 nm - 1030 nm 2 | 1030 nm 2 | 1030 / 1075 nm |

| Leistung | bis 2000 W (cw) | bis 2000 W (cw) | bis 12000 W (cw) | bis 8000 W (cw) | bis 8000 W (cw) |

PFO SF20: bis 8000 W (cw)

PFO SF33: bis 12000 W (cw) |

| Numerische Apertur | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 | typ. 0,11 / max. 0,12 |

| Typ Laserlichtkabel | LLK-D, LLK-B, LLK-A | LLK-D, LLK-B, LLK-A | LLK-D | LLK-D, LLK-B | LLK-D | LLK-D |

| Optikkonfiguration 1 | ||||||

| Kollimation | 35 / 56 mm | 35 / 56 / 80 / 90 / 100 mm |

140 mm (TruDisk & TruFiber Multi Mode)

150 / 200 / 300 mm (TruFiber Single Mode) |

150 mm | 138 mm |

PFO SF20: 90 mm (TruDisk, TruMicro 7000, TruFiber Multi Mode)

PFO SF20: 150 / 200 mm (TruFiber Single Mode) PFO SF33: 140 mm (TruDisk, TruMicro 7000, TruFiber Multi Mode) |

| Brennweite | 100 / 160 / 163 / 254 / 330 / 420 mm | 90 / 100 / 135 / 160 / 163 / 200 / 254 / 264 / 280 / 330 / 395 / 420 / 560 / 740 mm |

255 / 345 / 450 mm (Standard)

160 / 265 / 345 / 450 / 600 mm (HighBrightness) |

150 / 200 / 300 mm | 255 / 345 / 450 / 600 / 900 mm | 200 / 300 / 400 / 500 / 600 mm |

| z-Hub bei Objektivbrennweite | - | - | - | - |

f255: ± 22 mm

f345: ± 40 mm f450: ± 70 mm f600: ± 100 mm f900: ± 220 mm |

- |

| Feldgröße (Ellipse Y x X) bei Objektivbrennweite |

f100: 47 mm x 18 mm

f160: 110 mm x 75 mm f163: 110 mm x 70 mm f254: 170 mm x 120 mm f330: 220 mm x 178 mm f420: 286 mm x 230 mm |

f100: 50 mm x 36 mm

f135: 70 mm x 50 mm f160: 86 mm x 66 mm f264: 180 mm x 136 mm |

- | - |

f255: 174 mm x 102 mm (z=0)

f345: 240 mm x 140 mm (z=0) f450: 320 mm x 190 mm (z=0) f600: 376 mm x 230 mm (z=0) f900: 525 mm x 340 mm (z=0) |

f200: 11 mm x 17 mm

f300: 17 mm x 25 mm f400: 22 mm x 34 mm f500: 28 mm x 42 mm f600: 28 mm x 42 mm |

| Feldgröße (Ellipse Y x X) bei Objektivbrennweite für TruDisk/TruMicro | - | - |

f255: 180 mm x 112 mm

f345: 244 mm x 150 mm f450: 320 mm x 196 mm |

- | - | - |

| Feldgröße (Ellipse Y x X) bei Objektivbrennweite für HighBrightness Objektive | - | - |

f160: 80 mm x 57 mm

f265: 140 mm x 102 mm f345: 208 mm x 152 mm f450: 306 mm x 208 mm f600: 388 mm x 257 mm |

- | - | - |

| Feldgröße (Ellipse Y x X) bei Objektivbrennweite für TruFiber | - | - |

f265: 140 mm x 102 mm

f345: 208 mm x 152 mm f450: 306 mm x 208 mm f600: 388 mm x 257 mm |

- | - | - |

| Feldgröße (Ellipse Y x X) bei Objektivbrennweite für TruDisk 515 nm | - | - |

f160: 77 mm x 56 mm

f265: 140 mm x 102 mm f345: 202 mm x 144 mm f450: 312 mm x 190 mm |

- | - | - |

| Bauform | ||||||

| Abmessungen (B x H x T) | 278 mm x 391 mm x 202 mm (Beispielkonfiguration mit fc56 und f160) | 278 mm x 296 mm x 202 mm (Beispielkonfiguration mit fc90 und f264) | 336 mm x 340 mm x 227 mm (Beispielkonfiguration mit fc140 und f450) | 227 mm x 562 mm x 229 mm | 412 mm x 266 mm x 366 mm |

223 mm x 200 mm x 198 mm (Scannerkopf ohne Objektiv)

120 mm x 195 mm x 252 mm (PFO Steuereinheit) |

| Gewicht | 15 kg | 15 kg |

< 35 kg

< 38 kg mit OCT-Scanner |

12,5 kg | 35 kg |

13 kg (Scannerkopf)

4 kg (PFO Steuereinheit) |

| Kompatibilität | ||||||

| Verfügbare Laser | TruDiode, TruDisk, TruMicro | TruDiode, TruDisk, TruFiber, TruMicro, TruPulse | TruDisk, TruFiber, TruMicro | TruDiode, TruDisk | TruDisk |

PFO SF20: TruDisk, TruMicro 7000, TruFiber Multi Mode, TruFiber Single Mode

PFO SF33: TruDisk, TruMicro 7000, TruFiber Multi Mode |

| Verfügbare Sensorik | - | VisionLine, CalibrationLine, Temperaturregelung zum Kunststoffschweißen und zum Härten | VisionLine Cam/Basic/Detect, VisionLine OCT Detect, CalibrationLine | - | VisionLine, CalibrationLine, SeamLine Remote, OCT Nahtlageregelung | VisionLine Cam/Basic/Detect, CalibrationLine |

| Optionen | ||||||

| Verfügbare Optionen | Crossjet, Kamerabeobachtung | Crossjet, Sensorikschnittstelle, Beleuchtung | Crossjet, MDE-Düse, Schmauchglocke, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Schutzglasüberwachung | Crossjet, MDE-Düse, Schutzgaszufuhr, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Kassettenmodul, Schutzglasüberwachung | Ausführung als I-PFO, Crossjet, MDE-Düse, Schmauchglocke, Beleuchtung | Crossjet, MDE-Düse, verschiedene Schutzgasdüsen, Kamerabeobachtung, Sensorikschnittstelle, Beleuchtung, Schutzglasüberwachung, Kühlwasserüberwachung |

| Verfügbare Software-Optionen | TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App, Real-time contour check | - | TruTops I-PFO und TruTops PFO, PFO Smart Teach App | TruTops PFO, PFO Smart Teach App, Real-time contour check |

Die technischen Daten aller Produktvarianten als Download.

PFO 1D

Die programmierbare Fokussieroptik PFO 1D vereint die Vorteile zweier Welten: die Robustheit der industriebewährten TRUMPF Festoptiken und die Scanner-Funktionalität der programmierbaren Fokussieroptiken (PFO). Durch eine individuell einstellbare 1D-Wobbel-Bewegung des Laserstrahls profitieren Sie von höchster Schweißnahtqualität sowohl bei Wärmeleitschweiß- als auch bei Tiefschweißanwendungen.

Laser: TruDisk

Max. Laserleistung: 8 kW (cw)

PFO 14 / PFO 20-2

Die programmierbare Fokussieroptiken PFO 14 und PFO 20-2 eignen sich ideal für das Punktschweißen oder Bahnschweißen mit hohen Geschwindigkeitsanforderungen. Die 2D-Scanner funktionieren nach dem pre-objective-scanning-Prinzip. Damit erreichen sie bei nahezu konstantem Arbeitsabstand alle Punkte im Bearbeitungsbereich des Scanners mit hoher Dynamik und konstanter Strahlqualität. Außerdem profitieren sie von einem unkomplizierten Objektivtausch, da Kalibrierdaten in einer Speichereinheit am Objektiv abgelegt sind. Komplexe Bauteile können Sie einfach mit mehreren Schweißnähen zusammenfügen.

Laser: TruDisk, TruDiode, TruFiber, TruMicro

Max. Laserleistung: 300 W (TruDiode), 2000 W (TruDisk, TruFiber, TruMicro)

PFO 33

Die dritte Generation der PFO 33 steht für höchste Produktivität und kann für Applikationen mit einer Laserleistung von bis zu 12 kW eingesetzt werden. Die Leichtbauspiegel sowie die neue Antriebsarchitektur ermöglichen eine maximale Dynamik. Gleichzeitig verbessern optimierte mechanische und optische Baugruppen die Robustheit der Optik gegenüber Rückreflexen. Optionen wie die Schutzglasüberwachung und Condition Monitoring helfen dabei die Verfügbarkeit Ihrer Produktion zu maximieren.

Laser: TruDisk, TruFiber, TruMicro

Max. Laserleistung: 12 kW (cw)

PFO 3D-2

Die programmierbare Fokussieroptik PFO 3D-2 ist ein 3D-Scanner, der ebenfalls auf dem dem pre-objective-scanning-Prinzip basiert. Damit lassen sich, bei variablem Arbeitsabstand, alle Punkte im Bearbeitungsbereich des Scanners mit hoher Dynamik und gleichbleibender Strahlqualität erreichen. Sämtliche Bearbeitungsprogramme sind lokal in der PFO gespeichert, was auch einen Betrieb ohne PC ermöglicht. Den 3D-Scanner erhalten Sie optional mit der TRUMPF Offline-Simulationssoftware TruTops I-PFO, der Nahtverfolgung mit Triangulation SeamLine Remote und dem Kalibrationswerkzeug CalibrationLine.

Laser: TruDisk

Max. Laserleistung: 8 kW (cw)

I-PFO

Die perfekte Softwarelösung für das Laserschweißen von komplexen Herausforderungen. Die Software TruTops I-PFO vereinfacht das Einrichten und Anpassen von komplexen Aufgaben, die mit Industrieroboter und PFO 3D Schweißoptik gelöst werden müssen.

PFO SF

Der Kleinfeldscanner PFO SF ist der kompakte und vielseitige Scanner mit kleinem Arbeitsraum für schnelle Strahloszillation.

Mit der Auswahl der passenden Optionen (Objektiv, Kollimator und Sensorik) lässt sich der Kleinfeldscanner flexibel an Ihre Anwendung anpassen. Die PFO SF ist für einen Leistungsbereich von bis zu 12 kW geeignet. Sie ist nicht nur leistungsstark, sondern auch smart mit Funktionen wie der Schutzglasüberwachung. Darüber hinaus kann die Optik in die gesamte TRUMPF Lösungswelt integriert werden.

Laser: TruDisk, TruFiber, TruMicro

Max. Laserleistung: 12 kW (cw)

TruTops PFO

TruTops PFO ist eine Offline-Software zur 2D- und 3D-Programmierung Ihrer PFO. Sie definieren beliebige Pfade, Kanten oder Flächen der im CAD-Editor erstellten, oder von Extern geladenen Objekte als Schweißnähte. Gleichzeitig können Sie Spannvorrichtungen berücksichtigen, um die Schweißreihenfolge und damit die Bearbeitungszeit zu optimieren. Die Software ermöglicht Ihnen zudem die Programmierung unterschiedlicher Wobble-Methoden. Über das Netzwerk verbinden Sie TruTops PFO mit TruControl.

TruTops I-PFO

Um die Vorteile von intelligenter Remotebearbeitung zu nutzen, programmieren Sie die I-PFO mit TruTops I-PFO. Das Offline 3D-Entwicklungswerkzeug ermittelt den idealen Prozess und optimiert Pfad sowie Geschwindigkeit. Gleichzeitig können Sie Spannvorrichtungen berücksichtigen, um die Bahn des Roboters, die Schweißreihenfolge und damit die Bearbeitungszeit zu optimieren. Die Software analysiert außerdem die Taktzeit und stellt diese virtuell dar.

PFO SmartTeach

PFO SmartTeach ist eine Applikation für Ihre programmierbare Fokussieroptik der PFO-Serie. Sie erleichtert das Erstellen und Einrichten von Laserschweiß- und -schneidprogrammen. Die am C-Mount der Optik eingebaute Kamera überträgt das Livebild an die App. Dadurch teachen Sie komfortabel direkt am Bauteil. Wenn Sie PFO-Geometrien erstellen und einteachen möchten, können Sie dies über die intuitive Gestenbedienung am Tablet durchführen.

TRUMPF bietet Ihnen neben einer Vielzahl an Bearbeitungsoptiken auch die dazu passenden Maschinen und Strahlquellen. So finden Sie für Ihre Anwendung und Ihre Anforderungen genau die richtige Kombination – und das aus einer Hand. Im Bereich der Strahlquellen verfügt TRUMPF über alle industriell relevanten Laser. Verlassen Sie sich auf unsere Experten und vertrauen Sie uns, dass wir stets die beste Lösung für Ihre Fertigungsaufgaben im Blick haben und völlig unabhängig von einer präferierten Technologie beraten.

Erweitern Sie die programmierbare Fokussieroptik PFO durch eine Vielzahl innovativer Funktionen.

Verschiedene Kameras können direkt an die PFO adaptiert werden. Ein digitales Farb-Kamerasystem ermöglicht etwa die scharfe Erkennung von Konturen und Kanten. Die Software der PFO unterstützt die Kamerabedienung per Touchscreen, ein digital einstellbares Fadenkreuz oder das Speichern von Bildern. Selbst bei dunklen Lichtverhältnissen sorgt die koaxiale und damit richtungsunabhängige Beleuchtung für vollen Durchblick.

Die intelligente Fokussieroptik PFO (I-PFO) kennt ihre eigene Position im Arbeitsraum des Roboters sowie die Lage und Orientierung der Bearbeitungsstellen. Auf Basis von Informationen über die aktuelle Roboterbewegung, startet die I-PFO eigenständig die Bearbeitung, sobald dies geometrisch und prozesstechnisch möglich ist. Somit ist eine Remotebearbeitung "on-the-fly" möglich, die sowohl die Positionierungszeiten des Roboters als auch die Taktzeiten in Ihrer Fertigung stark reduziert.

PFO SmartTeach ist eine Applikation für Ihre programmierbare Fokussieroptik der PFO-Serie. Sie erleichtert das Erstellen und Einrichten von Laserschweiß- und -schneidprogrammen. Die am C-Mount der Optik eingebaute Kamera überträgt das Livebild an die App. Dadurch teachen Sie komfortabel direkt am Bauteil. Wenn Sie PFO-Geometrien erstellen und einteachen möchten, können Sie dies über die intuitive Gestenbedienung am Tablet durchführen.

Der Crossjet ist ein orthogonal zum Laserstrahl verlaufender Druckluftstrom. Er lenkt Schmutz und Spritzer ab und verlängert so die Schutzglasstandzeit. Der Laserprozess wird robuster.

Je nach Land sind Abweichungen von diesem Produktsortiment und von diesen Angaben möglich. Änderungen in Technik, Ausstattung, Preis und Zubehörangebot sind vorbehalten. Bitte setzen Sie sich mit Ihrem Ansprechpartner vor Ort in Verbindung, um zu erfahren, ob das Produkt in Ihrem Land verfügbar ist.

Fußnoten-

Weitere Optikkonfigurationen auf Anfrage möglich.

-

Weitere Wellenlängen auf Anfrage möglich.