Fastest storage connection

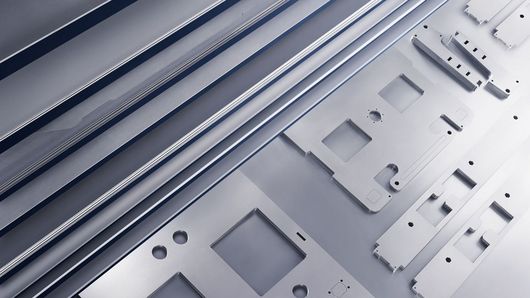

The frame solution, LiftMaster Store, is directly connected to the store and requires minimal space. In return, it offers more scope to design your production to meet your specific needs. Here, the LiftMaster Store is assisted by a number of tried-and-tested TRUMPF technologies. Examples include the suction frame with unloading rakes for automated loading and unloading, or the synchronous loader for increased productivity. With the independent pallet picker crane, the LiftMaster Store can quickly access pallets in the store. This makes it particularly well suited to automated scrap skeleton separation. Connection to up to three machines with multiple tool stations is made possible with the LiftMaster Store Linear.

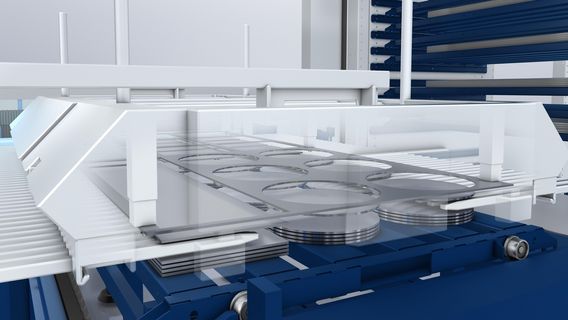

The LiftMaster Store accesses the store directly via a pallet picker crane.

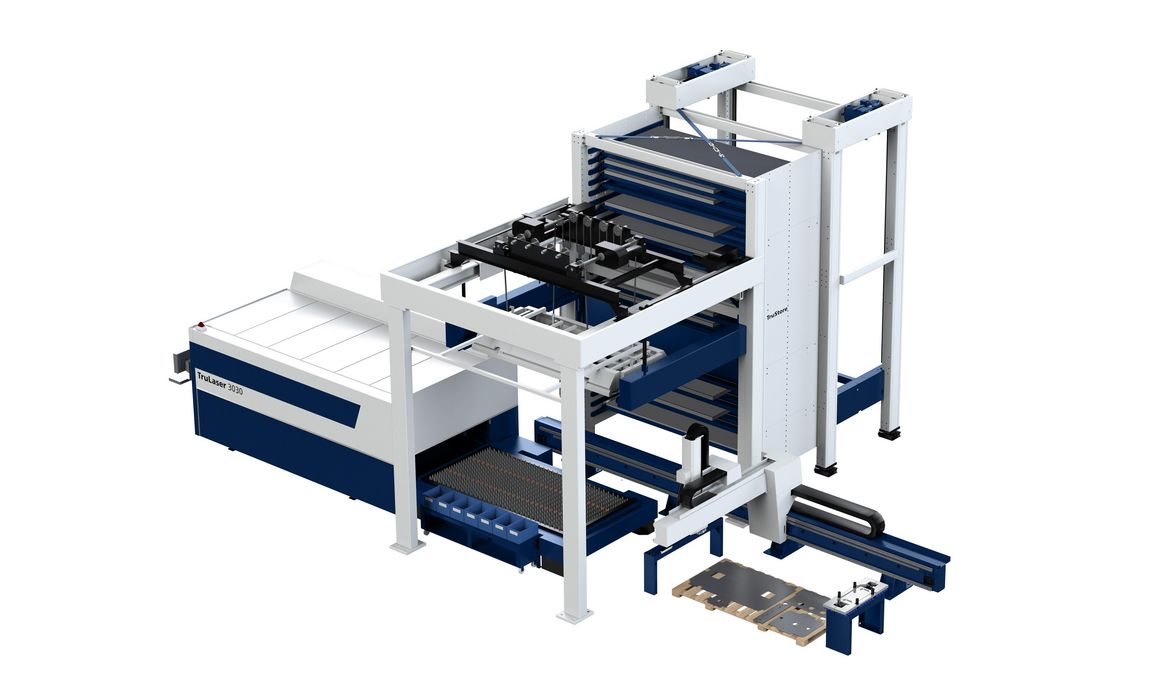

With TruStore and SortMaster you can easily upgrade your LiftMaster Store to a processing cell.

The LiftMaster Store requires just 100 seconds for a complete loading and unloading cycle, including pallet change with the synchronous loader.

Produce in a single stroke and at under a minute per sheet.

|

LiftMaster Store maxi format

|

LiftMaster Store large format

|

|

|---|---|---|

| Loading | ||

| Maximum sheet size | 4000 mm x 2000 mm | 3000 mm x 1500 mm |

| Minimum sheet size | 1000 mm x 1000 mm | 1000 mm x 1000 mm |

| Maximum sheet thickness | 30 mm | 30 mm |

| Maximum sheet weight | 1900 kg | 1100 kg |

| Unloading | ||

| Maximum sheet size | 4000 mm x 2000 mm | 3000 mm x 1500 mm |

| Minimum sheet size | 150 mm x 150 mm | 150 mm x 150 mm |

| Maximum sheet thickness | 30 mm | 30 mm |

| Maximum sheet weight | 1600 kg | 1100 kg |

The technical data of all product versions as a download.

Automated machines work more productively, support material handling and increase process reliability. Equip your automation components with clever features.

The LiftMaster Store quickly separates finished parts from the scrap skeleton. The suction frame is additionally equipped with spreadable grippers for this, which pick up the scrap skeleton in the unloading rake. The finished parts remain in the closed unloading rake and can be placed down in an unloading area. The suction frame then sets down the scrap skeleton. This option is only available for the LiftMaster Store 1530.

The unloading rake takes the finished, processed sheet from the pallet changer and sets it down in the unloading area. The suction frame is fitted with individually controllable suction cups that pick up the unprocessed sheets from the loading area, and set them down onto the pallet changer.

The SortMaster enables you to remove single parts right from the pallet changer. It places small parts into containers; larger parts are set on europallets or (store) carts, and sorted. With its individually controllable suction cups, the LiftMaster can transport a wide range of diverse parts. Useful upgrade options further widen the potential field of application.

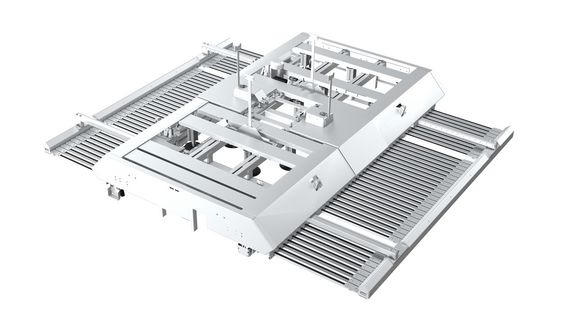

With the LiftMaster Store Linear you can load and unload up to three processing machines simultaneously. The TruTops FMC software is used to control and manage all components during multiple-machine operation. You can easily connect the LiftMaster Store Linear to a store.

The synchronous loader has a suction frame that transports a finished part pallet, onto which the cut sheets are placed. It traverses horizontally between the unprocessed material table and the pallet changer.

Auxiliary pallets support the loading and unloading process. The LiftMaster Store automatically takes care of their handling.

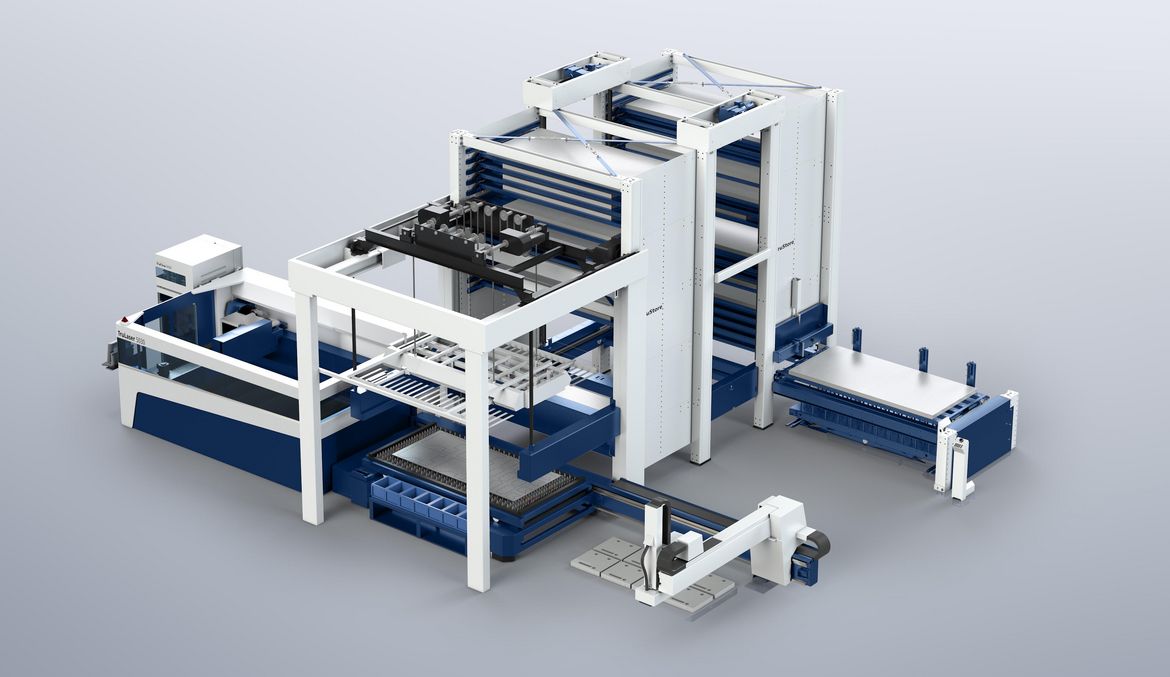

TruLaser 3030 fiber with SortMaster, TruStore 3030 and LiftMaster Store

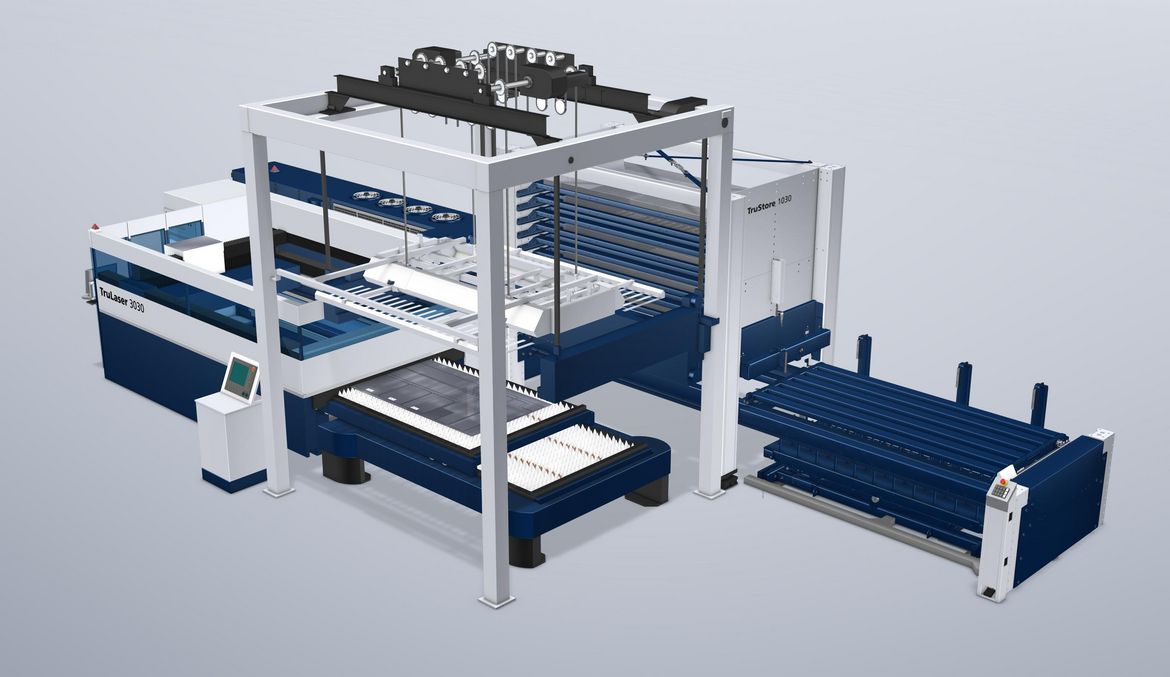

TruLaser 3030 with TruStore 1030 and LiftMaster Store

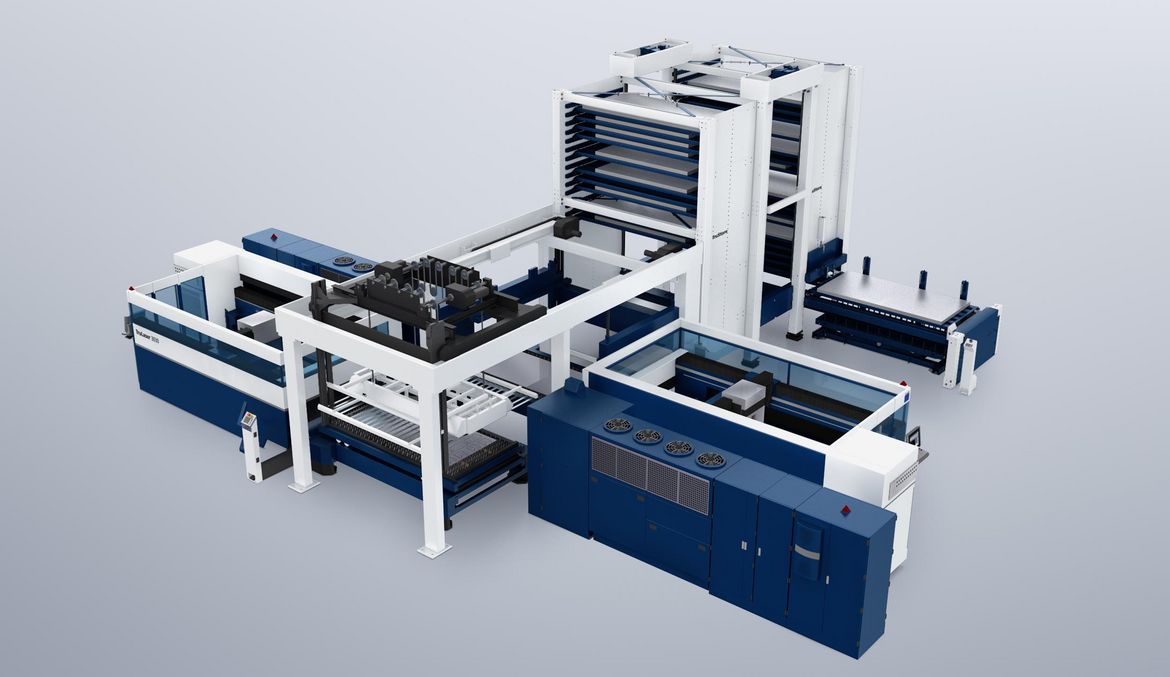

The LiftMaster Store connects a TruLaser 5030 directly to a TruStore 3030 and a SortMaster

Multiple-machine connection with the LiftMaster Store Linear and TruStore 3030

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.