Grows to meet your requirements

The TruStore Series 3000 tower storage system reduces space requirements and can be expanded to create a fully automatic system. Built on a modular principle, it can be expanded at any time – all the way up to a cutting and bending cell with multiple machines. You can select the height of your store from 17 possible levels and the storage compartments can be adjusted to 90, 170 or 260 mm. The storage system can be easily connected to your TRUMPF 2D laser cutting systems, punching machines, punch laser machines and bending machines.

Double your machine runtime and optimise your work processes for improved time and cost efficiency.

The TruStore Series 3000 saves up to 85% in installation area.

Expand your TruStore Series 3000 at any time using flexible connection options.

Store up to 210 tonnes in large format.

Gain full control over your material flow with transparent storage and inventory data through the Oseon software solution.

|

TruStore 3030

|

TruStore 3040

|

|

|---|---|---|

| Sheet size | 3048 mm x 1524 mm | 4064 mm x 2032 mm |

| Stack heights | 90 mm / 170 mm / 260 mm | 90 mm / 170 mm / 260 mm |

| Maximum loading per compartment | 3000 kg | 5000 kg |

Software

The software portfolio from TRUMPF optimises your entire production process – from the customer query to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customised Industry 4.0 solutions for your Smart Factory.

With additional equipment options, you can increase the capacity of the TruStore Series 3000.

Choose between large format (3000 x 1500 mm) with 3000 kg loading weight per compartment or maximum format (4000 x 2000 mm) with 5000 kg loading weight per compartment.

Store material on pallet levels at three storage heights: 90, 170 or 260 mm. Loading and unloading heights can be configured separately to suit your production operation and connected automations.

This storage tower with pallet lift lets you choose from 16 height levels between 3.4 and 8.4 m. The tower stores up to 37 large-format or 24 maximum-format pallets.

Expand the single tower storage system with a second storage tower for up to 38 extra storage pallets in large format or up to 25 extra storage pallets in maximum format. The tower's variable height can also be adjusted from around 3.4 to 8.4 metres.

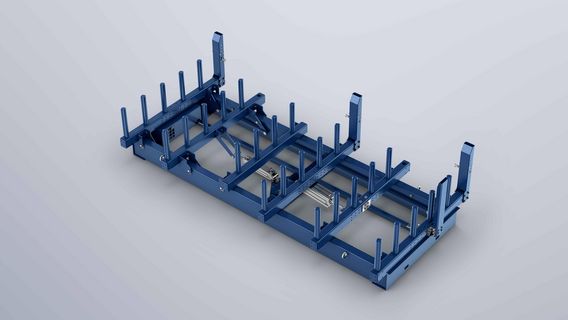

Load and unload your single tower directly at the pallet lift – with automatic folding support punches and stops, as well as access from one longitudinal side. This reduces time and costs through integration and quick installation.

The versatile cart allows for storage input and output on the longitudinal side, making it ideal for both tower systems. The traverse path adapts to your premises and processes. When the cart is outside the tower, you can access the pallets on all sides. Meanwhile, the pallet lift raises and lowers the material from the supporting punches on the cart.

You can load and unload with up to two carts at the front, which is ideal for both tower systems. You can customise the traverse path and direction to suit your conditions. When the cart is outside the tower, you can access the pallets on all sides. The cart has a lifting table with supporting punches that move the material directly

You can connect loading/unloading and sorting units such as the LoadMaster, LiftMaster, LiftMaster Linear, SheetMaster or BendMaster to the store using a transport cart. Choose between single and dual carts and customise the traverse paths to your premises. Automatic material supply increases productivity and machine runtime while reducing personnel requirements. Optimise your processes and buffer capacities with additional options.

Loading and unloading units such as LiftMaster Compact, LiftMaster Store or LiftMaster Store Linear can be connected alongside the storage tower. Direct access to storage pallets ensures minimal cycle times. Additionally, you save space and reduce personnel requirements, while enhancing productivity and machine runtime.

The modular design of the automations and storage systems enables step-by-step expansion of the cells at a later date – this ensures flexibility with a low investment risk.

In addition, you can optimise parts sorting with the optional PartMaster conveyor belt.

You can connect multiple machines to a TruStore Series 3000 storage system – either directly via towers or indirectly using transport carts.

It is also possible to connect multiple machines to the LiftMaster Linear or LiftMaster Store Linear automation variants.

Customise your store to meet your needs – pallet bases prevent small parts from falling through, and storage cassettes enable you to work with multiple machine auxiliary pallets. A weighing device in the pallet lift ensures continuous inventory tracking, while an unpacking table for separating raw materials from wooden pallets streamlines the workflow. Can't find the storage solution you want? Have a chat to us about it.

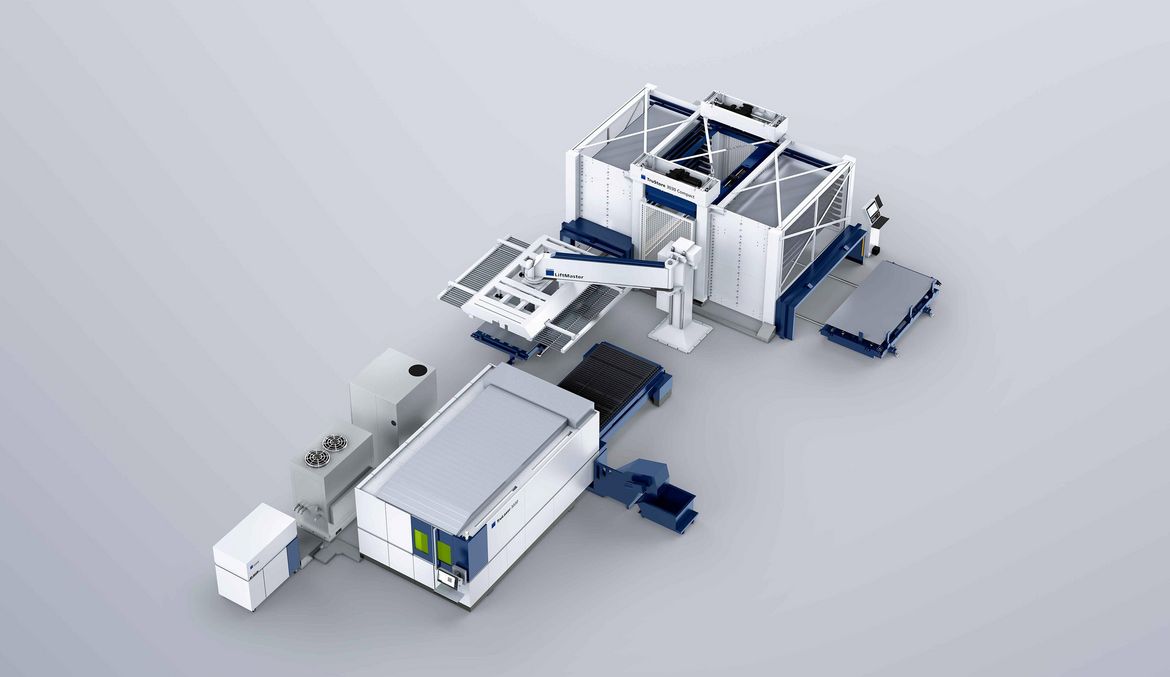

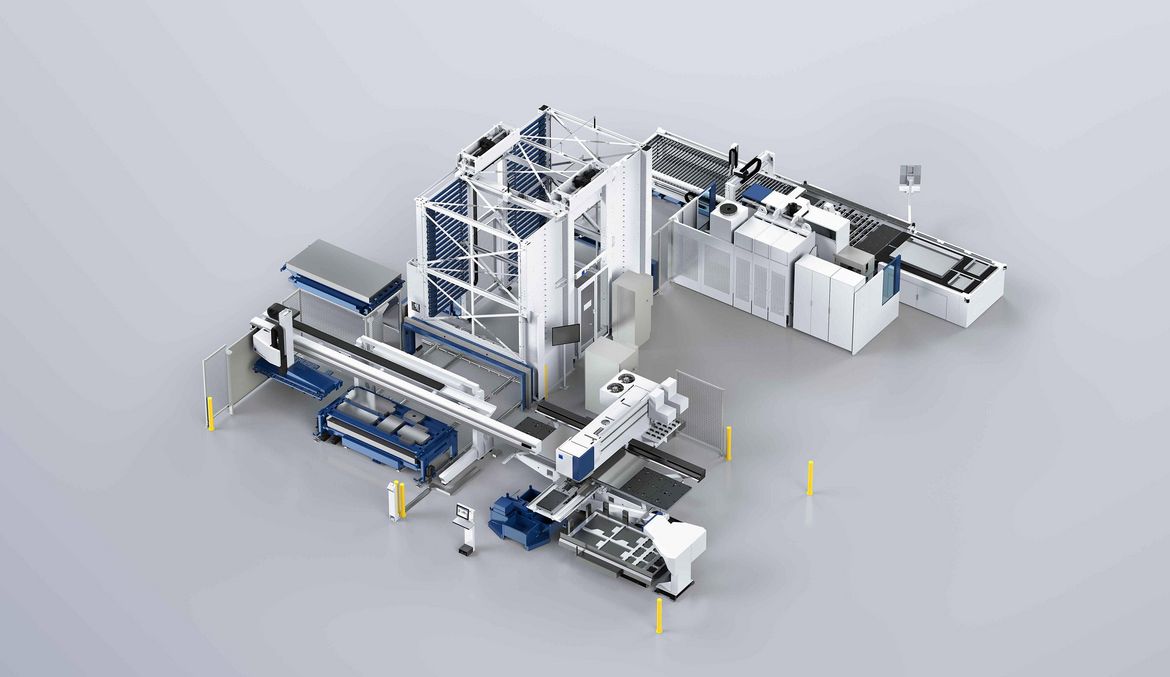

Laser cutting manufacturing solution with tower storage

Processing cell with 24 x 90 mm storage compartments: TruStore 3030 (3390 mm) double tower storage system, longitudinal storage input/output cart without lift, single cart at the front for indirectly connected LiftMaster loading/unloading automation on a TruLaser 3030 2D laser cutting system.

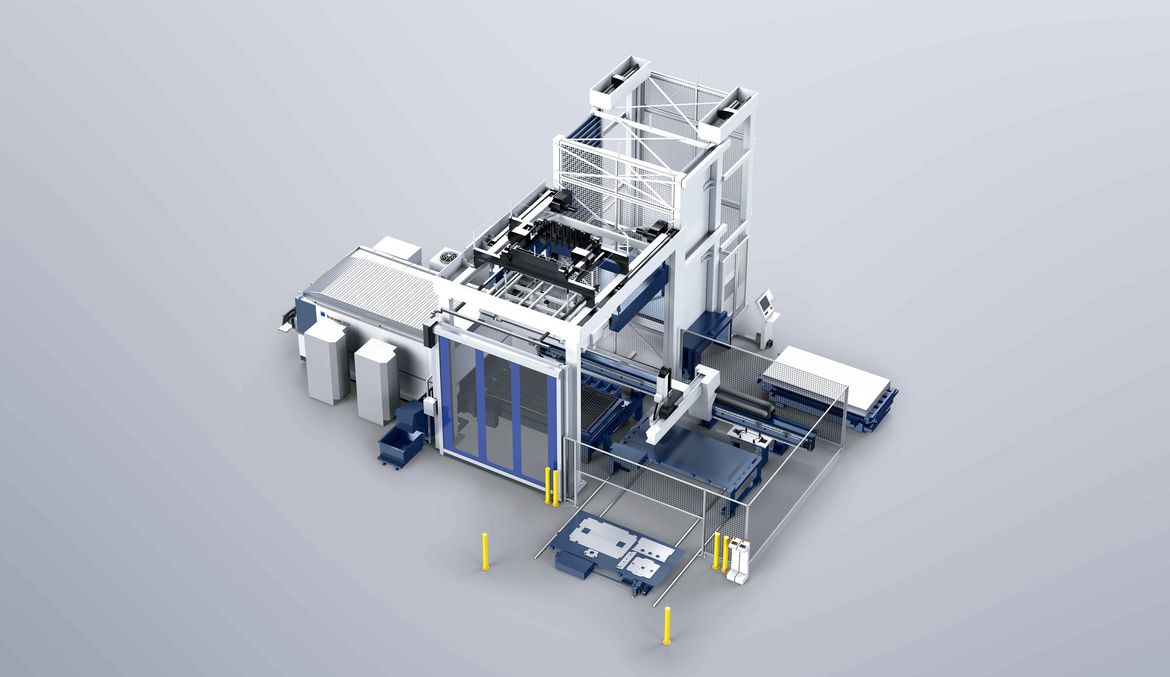

Laser cutting manufacturing solution with tower storage

Processing cell with 17 x 90 mm storage compartments: TruStore 3030 (5550 mm) single tower storage system, storage input/output station under pallet lift, directly connected LiftMaster Compact loading/unloading automation on the longitudinal side, and third pallet station on a TruLaser 3030 2D laser cutting system.

Laser cutting manufacturing solution with tower storage

Processing cell with 17 x 90 mm storage compartments: TruStore 3030 (5550 mm) single tower storage system, storage input/output station under pallet lift, directly connected LiftMaster Compact loading/unloading automation on the longitudinal side, with additional gantry station with PartMaster on a TruLaser 3030 2D laser cutting system.

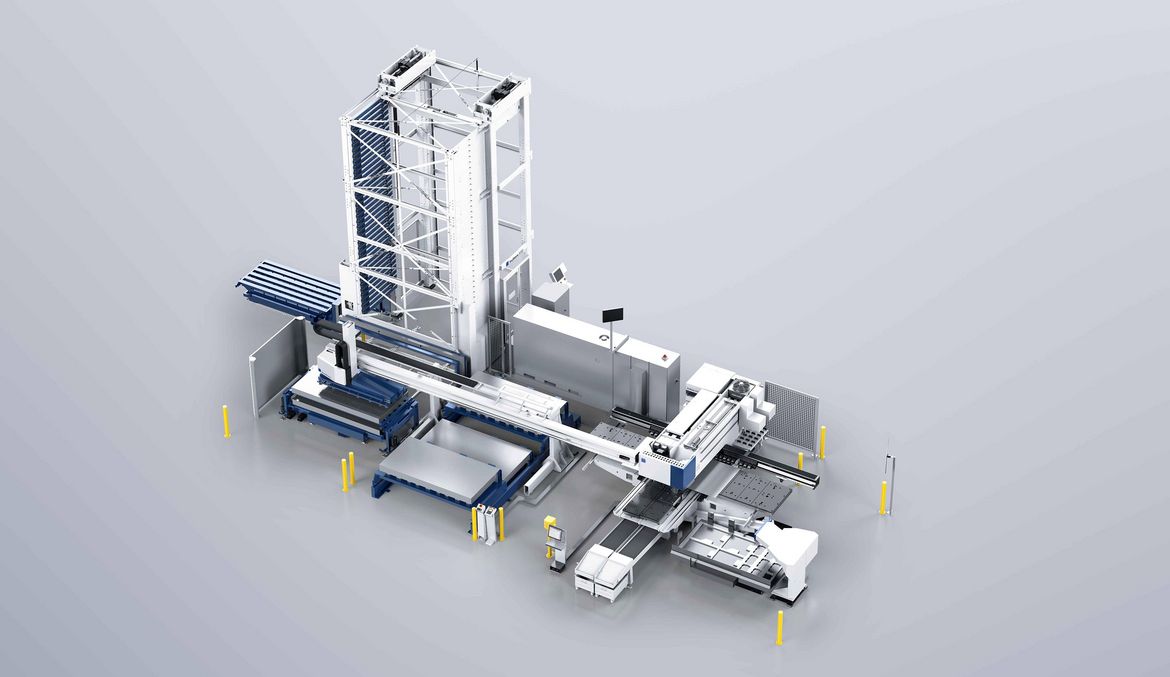

Laser cutting manufacturing solution with tower storage

Processing cell with 26 x 90 mm storage compartments: TruStore 3030 (8250 mm) single-tower storage system with storage input/output cart with lift at the front, directly connected LiftMaster Compact loading/unloading automation on the longitudinal side, and PartMaster parts conveyor belt on a TruLaser 3030 2D laser cutting system.

Reduced space requirements due to mezzanine installation of beam source, compact dust extractor and process cooler.

Laser cutting manufacturing solution with tower storage

Processing cell with 35 x 90 mm storage compartments: TruStore 3030 (5550 mm) double tower storage system with storage input/output cart with lift at the front, directly connected LiftMaster Compact loading/unloading automation on the longitudinal side, and PartMaster parts conveyor belt on a TruLaser 3030 2D laser cutting system.

Laser cutting manufacturing solution with tower storage (butterfly)

Processing cell with 25 x 90 mm storage compartments: TruStore 3030 (5550 mm) double tower storage system, storage input/output cart with lift at the front, 2x directly connected LiftMaster Compact loading/unloading automations on the longitudinal side, as well as 2x PartMaster part conveyor belts on 2x TruLaser 3030 2D laser cutting systems.

Laser cutting manufacturing solution with tower storage

Processing cell with 22 x 90 mm storage compartments: TruStore 3030 (5550 mm) single tower storage system, storage input/output cart with lift at the front, directly connected LiftMaster Store loading/unloading automation on the longitudinal side, and SortMaster sorting unit with dual unloading cart on a TruLaser 3030 2D laser cutting system. Quicker access to the machine's pallet changer is made possible by an optional roller gate.

Laser cutting manufacturing solution with tower storage

Processing cell with 36 x 90 mm storage compartments: TruStore 3030 (5010 mm) double tower storage system with storage input/output cart with lift at the front and indirectly connected TruLaser Center 7030 full-service laser machine on the longitudinal side.

Punch/laser processing manufacturing solution with tower storage

Processing cell with 34 x 90 mm storage compartments: TruStore 3030 (8250 mm) single tower storage system, storage input/output cart with lift at the front, longitudinal double cart with indirectly connected SheetMaster loading/unloading/sorting automation on a TruMatic 7000 punching/laser cutting machine.

Punch/laser processing manufacturing solution with tower storage (butterfly)

Processing cell with 71 x 90 mm storage compartments: TruStore 3030 (8250 mm) double tower storage system, storage input/output cart with lift at the front, double cart at the front and single cart at the rear on the longitudinal side with 2x indirectly connected SheetMaster loading/unloading/sorting automations on 2x TruMatic 7000 punching/laser cutting machines.

Manufacturing solution for punching and panel bending with tower storage

Processing cell with 43 x 90 mm storage compartments: TruStore 3030 (5550 mm) double tower storage system, storage input/output cart with lift at the front, double cart at the front and single cart at the rear on the longitudinal side with indirectly connected SheetMaster loading/unloading/sorting automation on a TruPunch 5000 punching machine and a TruBend Center 7030 panel bender.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.