Fast and economical connection

Joining is the simplest and most cost-effective way of connecting two or more metal parts. With the TruTool TF 350 you can produce a form-fitting connecting element with joints that are easy to reproduce from the material with cold forming. Whether the workpieces are coated or uncoated is irrelevant. The TruTool TF 350 joins total material thicknesses of 0.8 mm to max. 4 mm. The result is a long-lasting connection in one operation, without additional connecting elements.

The connection point is secure and resilient and the joining points are resistant to corrosion.

No screws or rivets are used, which saves costs and simplifies handling

The joining quality does not depend on whether surfaces are coated or uncoated.

Simple single stroke activation with consistent strength and connection quality.

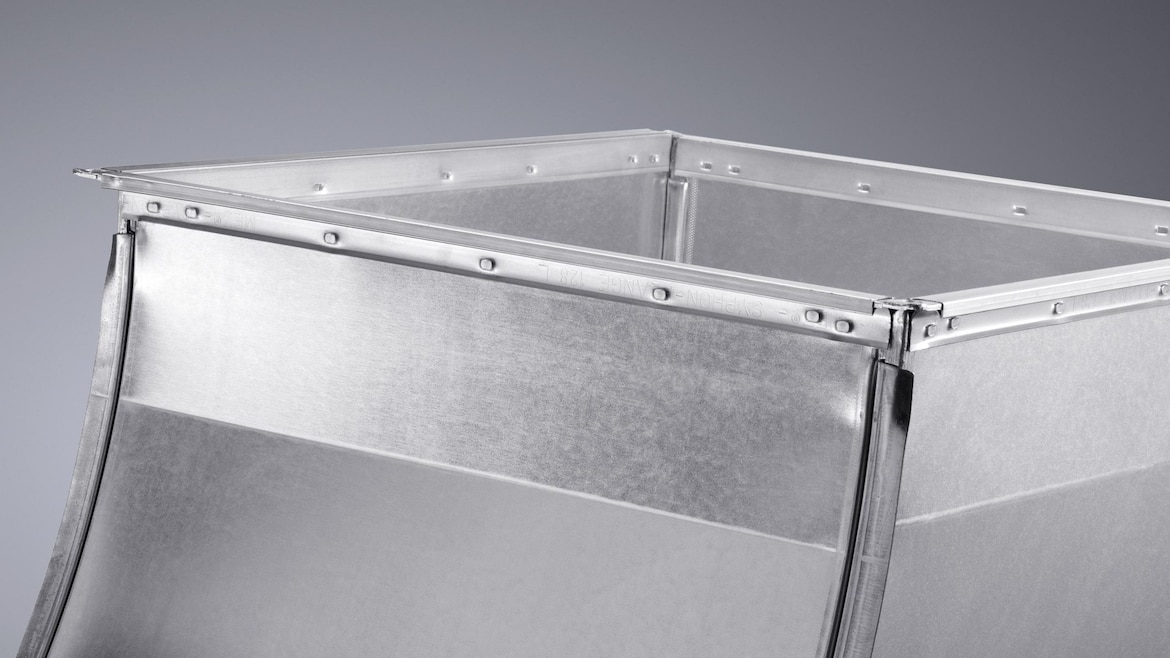

Joining ducts

Up to three parts can be connected together, even if the sheet thickness varies. For coated sheet metal, mild steel, stainless steel, aluminium or with intermediate layers such as adhesive and plastic mats.

Joining frame profiles

For joining connection flanges on ventilation and heating ducts.

The following consumables and the corresponding accessories are included in the scope of delivery.

Find the right consumables and accessories for your machine here.

Well-suited to sheet thicknesses of 1.6 - 2 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 1.6 - 2 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 2.6 - 3 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 3.1 - 3.5 mm. You can choose between five different dies depending on the material thicknesses: 1, 2, 2+, 3- or 3.

For quick and easy joining together of smaller sheet parts. Well-suited for stationary use.

Well-suited to sheet thicknesses of 0.8 - 1.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 2.6 - 3 mm. You can choose between five different dies depending on the material thicknesses: 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 3.1 - 3.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 2.6 - 3 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 2.1 - 2.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 1.6 - 2 mm. You can choose between five different dies depending on the material thicknesses: 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 2.1 - 2.5 mm. You can choose between five different dies depending on the material thicknesses: 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 2.1 - 2.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 3.1 - 3.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 0.8 - 1.5 mm. You can choose between five different dies depending on the material thicknesses: 1, 2, 2+, 3- or 3.

For hanging up the machine on a balancer. Enables fatigue-free work with maximum movement.

Well-suited to sheet thicknesses of 0.8 - 1.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Straight to the point

With displacement joining, the sheets of metal to be joined are placed on top of each other. Then the tool cuts a strip into the sheets in a combined punching and forming operation. The top sheet is joined with the lower one with a form-fitting and corrosion-resistant connection as the materials flow into one another. The connection point solidifies and you get a permanent connection without the need for filler materials or heat.

No connecting elements

The rectangular joining point appears as a shallow raised spot. This means that you have no interference contour, such as with edges for example, which you find with screws and rivets. The simple handling offers the benefit that no connecting elements need to be provided and the machine is therefore quickly ready for use. The TruTool TF 350 can also be adapted to the desired application quickly and easily. Simply choose the relevant tool.

User-friendly

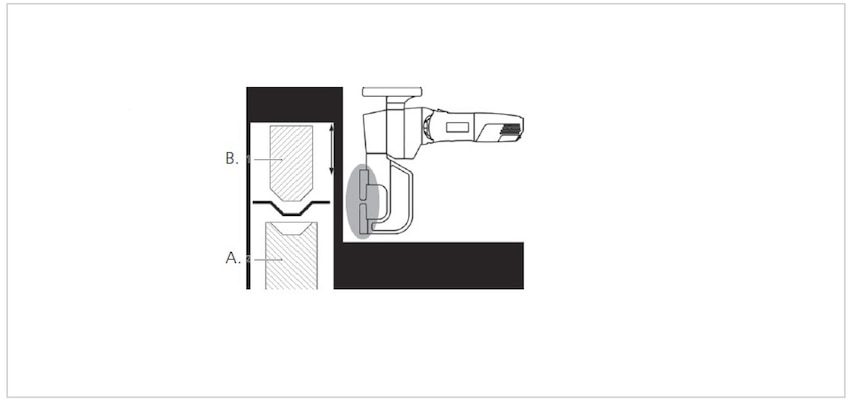

The TruTool TF 350 power fastener offers an impressively compact and slim design, which makes it particularly well-suited to uses where space is limited. The geometry of the tool also has a large throat depth with a minimal interference contour. This produces flawless connections when processing ventilation ducts. Applications on tight corners and small flange widths are also no problem for the TruTool TF 350.

Perfect surface

The joining zone is exposed to neither thermal loading nor tension. The protective layer flows with the material during forming. This means that the material properties remain unchanged and free of oxidation, and the surface structure is not damaged. There is no need for preliminary work or reworking. A further benefit is that with clinching you avoid contamination of the material surface. This is perfect for coated and uncoated materials; even sheet metal with a layer of oil is ideally suited to this.

|

TruTool TF 350

|

|

|---|---|

| Maximum sheet thicknesses | |

| Maximum sheet thickness, steel 400 N/mm² | 3.5 mm |

| Maximum sheet thickness, steel 600 N/mm² | 2.5 mm |

| Maximum sheet thickness, aluminium up to 250 N/mm² | 4 mm |

| General | |

| Maximum joining force | 25 kN |

| Maximum stroke rate | 2 1/s |

| Minimum edge spacing | 8 mm - 58 mm |

| Maximum flange height (B) | 36 mm |

| Nominal power consumption | 1700 W |

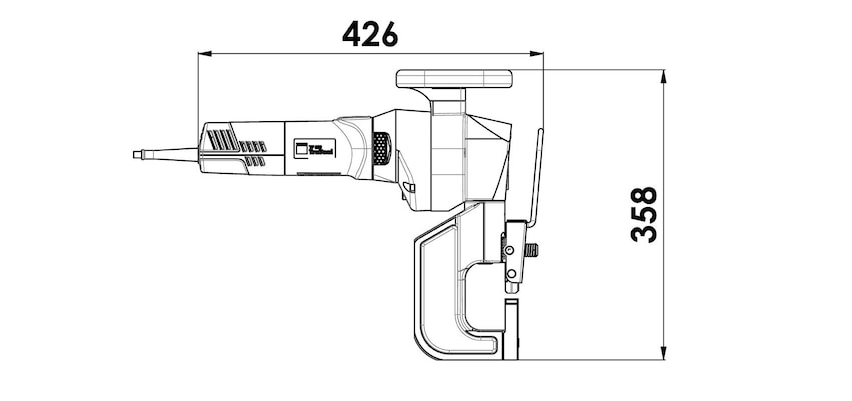

| Dimensions | |

| Length | 411 mm |

| Height | 358 mm |

| Weight | |

| Weight | 8.3 kg |

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.