Fast and economical connection

Joining is the simplest and most cost-effective way of connecting two or more metal parts. With the TruTool TF 350 you can produce a form-fitting connecting element with joints that are easy to reproduce from the material with cold forming. Whether the workpieces are coated or uncoated is irrelevant. The TruTool TF 350 joins total material thicknesses of 0.8 mm to max. 4 mm. The result is a long-lasting connection in one operation, without additional connecting elements.

The connection point is secure and resilient and the joining points are resistant to corrosion.

No screws or rivets are used, which saves costs and simplifies handling

The joining quality does not depend on whether surfaces are coated or uncoated.

Simple single stroke activation with consistent strength and connection quality.

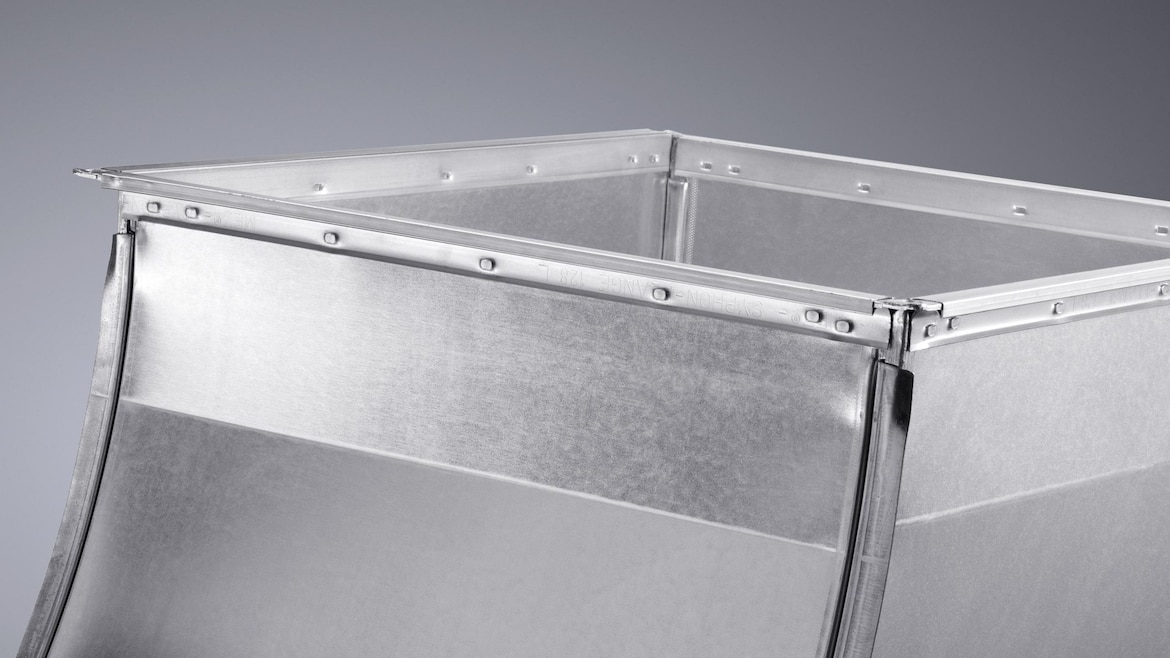

Joining ducts

Up to three parts can be connected together, even if the sheet thickness varies. For coated sheet metal, mild steel, stainless steel, aluminium or with intermediate layers such as adhesive and plastic mats.

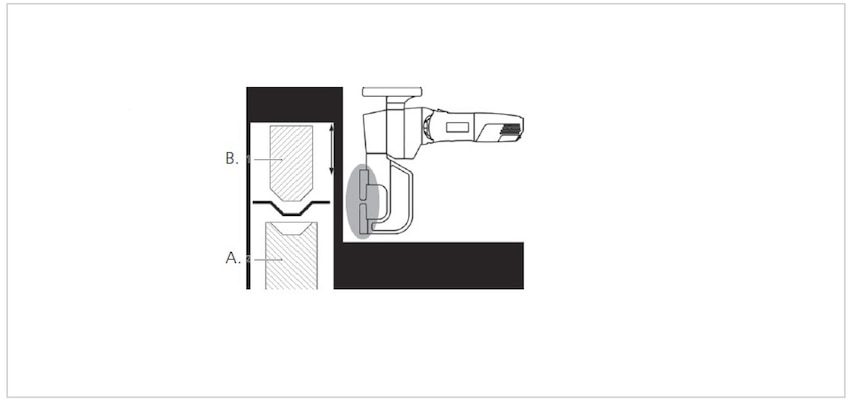

Joining frame profiles

For joining connection flanges on ventilation and heating ducts.

The following consumables and the corresponding accessories are included in the scope of delivery.

Find the right consumables and accessories for your machine here.

Well-suited to sheet thicknesses of 1.6 - 2 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 1.6 - 2 mm. You can choose between five different dies depending on the material thicknesses: 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 2.6 - 3 mm. You can choose between five different dies depending on the material thicknesses: 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 2.1 - 2.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 2.6 - 3 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 0.8 - 1.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 1.6 - 2 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 3.1 - 3.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 2.6 - 3 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 2.1 - 2.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 3.1 - 3.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

For hanging up the machine on a balancer. Enables fatigue-free work with maximum movement.

Well-suited to sheet thicknesses of 0.8 - 1.5 mm. You can choose between five different dies depending on the material thicknesses: 1, 2, 2+, 3- or 3.

For quick and easy joining together of smaller sheet parts. Well-suited for stationary use.

Well-suited to sheet thicknesses of 2.1 - 2.5 mm. You can choose between five different dies depending on the material thicknesses: 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 3.1 - 3.5 mm. You can choose between five different dies depending on the material thicknesses: 1, 2, 2+, 3- or 3.

Well-suited to sheet thicknesses of 0.8 - 1.5 mm. Can be selected with die No. 1, 2, 2+, 3- or 3.

Straight to the point

No connecting elements

User-friendly

Perfect surface

|

TruTool TF 350

|

|

|---|---|

| Maximum sheet thicknesses | |

| Maximum sheet thickness, steel 400 N/mm² | 3.5 mm |

| Maximum sheet thickness, steel 600 N/mm² | 2.5 mm |

| Maximum sheet thickness, aluminium up to 250 N/mm² | 4 mm |

| General | |

| Maximum joining force | 25 kN |

| Maximum stroke rate | 2 1/s |

| Minimum edge spacing | 8 mm - 58 mm |

| Maximum flange height (B) | 36 mm |

| Nominal power consumption | 1700 W |

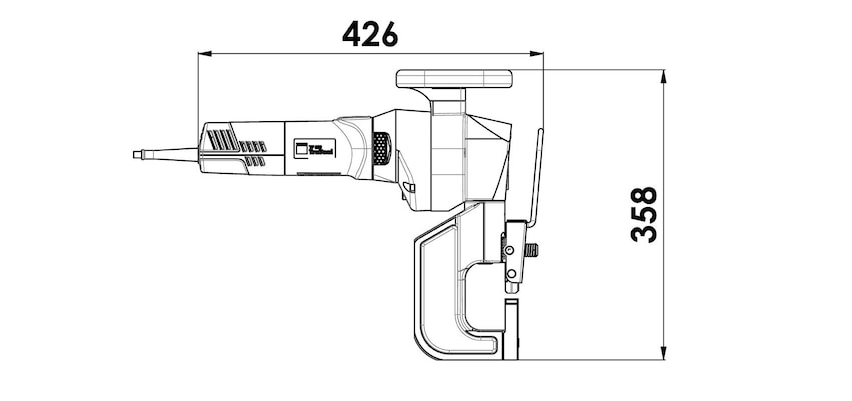

| Dimensions | |

| Length | 411 mm |

| Height | 358 mm |

| Weight | |

| Weight | 8.3 kg |

The technical data of all product versions as a download.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.