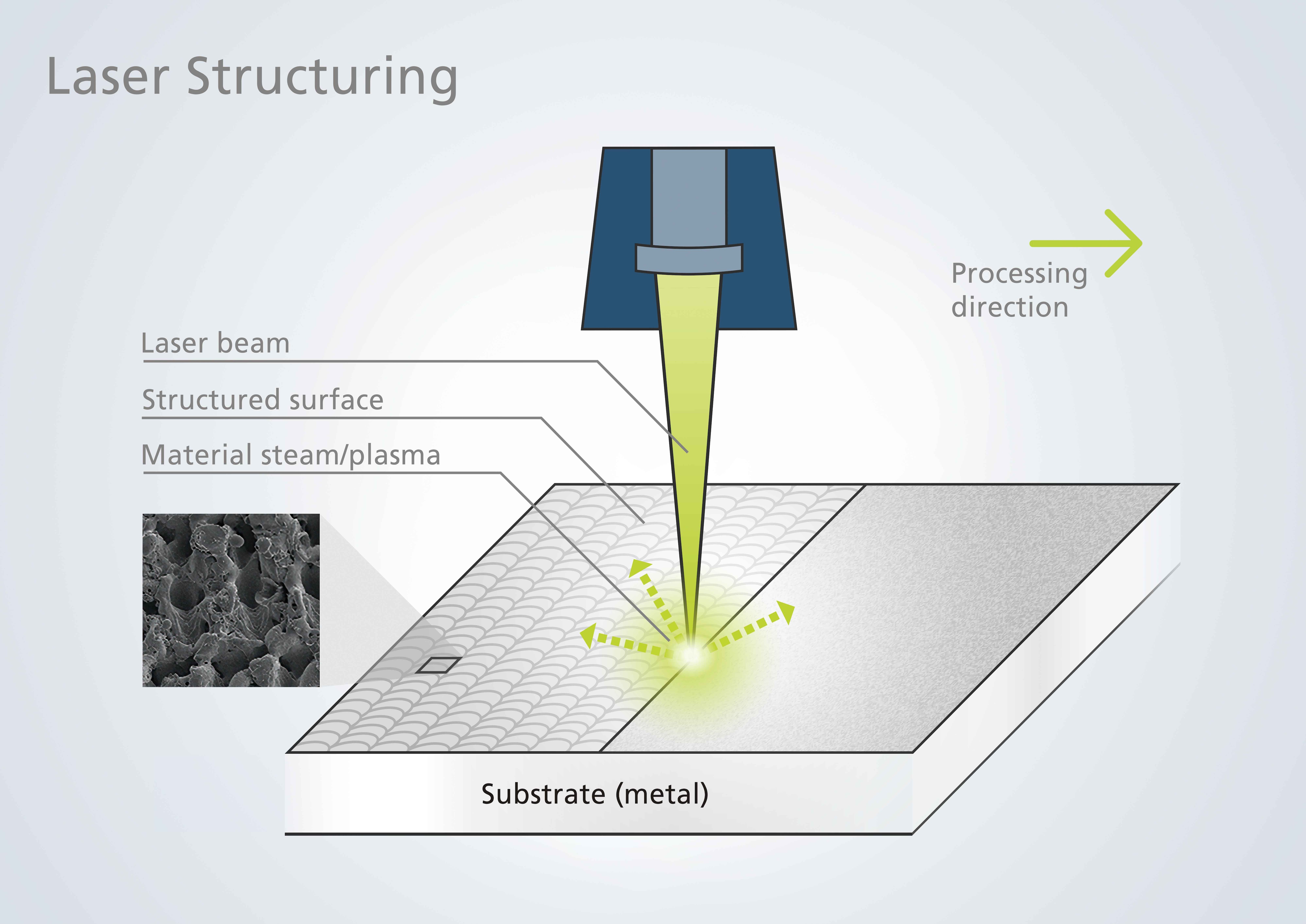

In laser structuring, regularly arranged geometries are generated in surfaces in a reproducible way using laser radiation (usually pulsed). The laser beam melts the material in a controlled manner and solidifies into a defined structure thanks to appropriate process management.

1. The laser radiation hits the workpiece surface.

2. The laser radiation heats the absorbing material.

3. Structures are generated as the melt solidifies.