Fully automated bending perfection - for complex sheet metal parts and maximum productivity in the Smart Factory

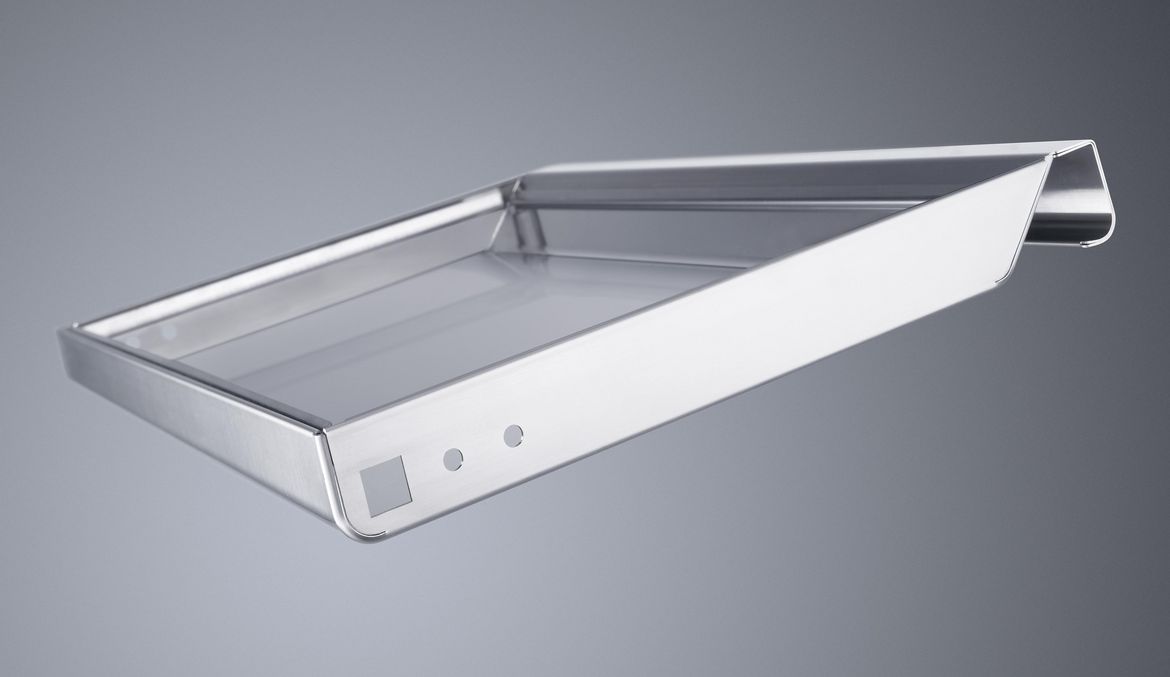

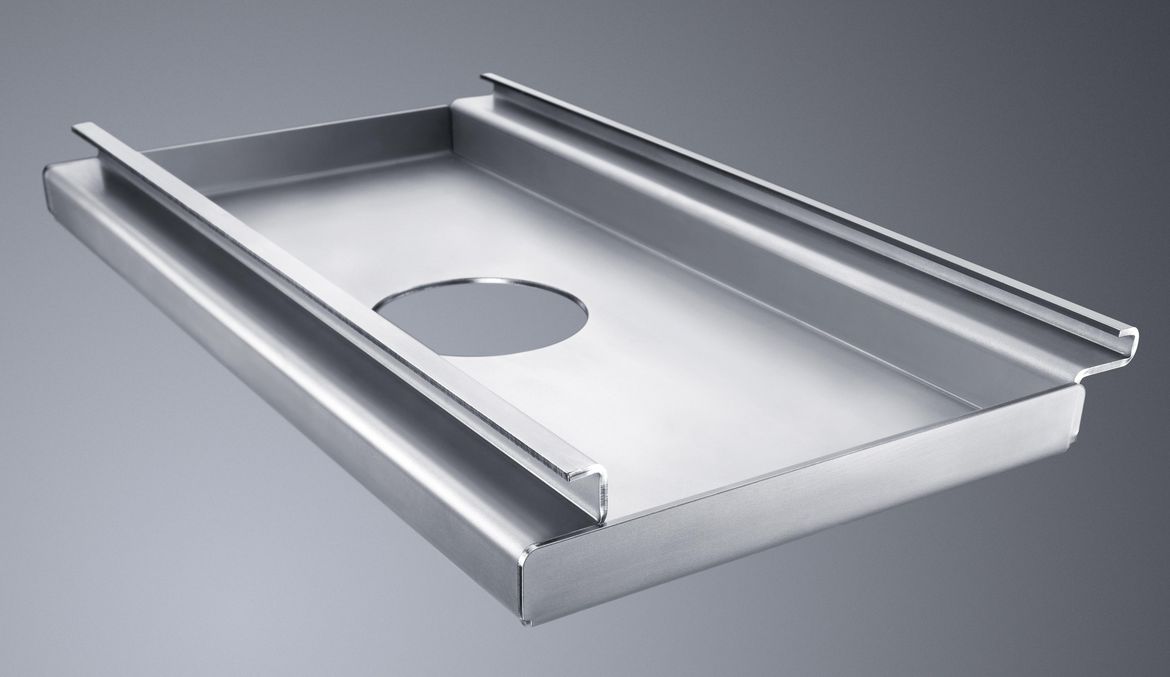

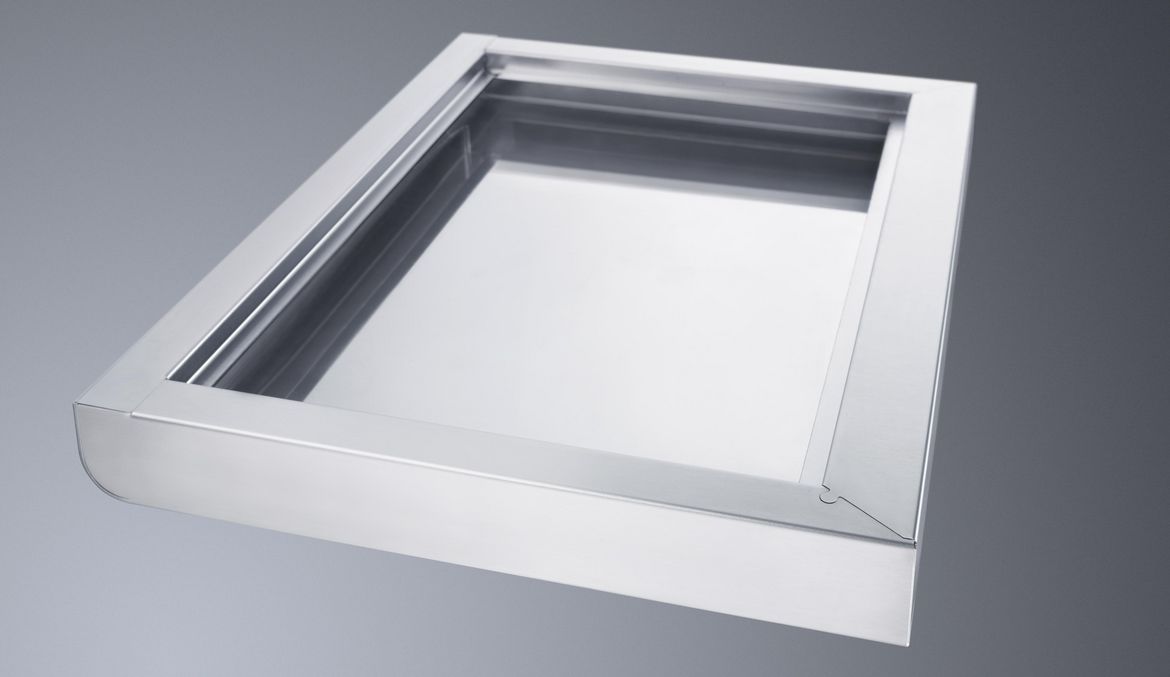

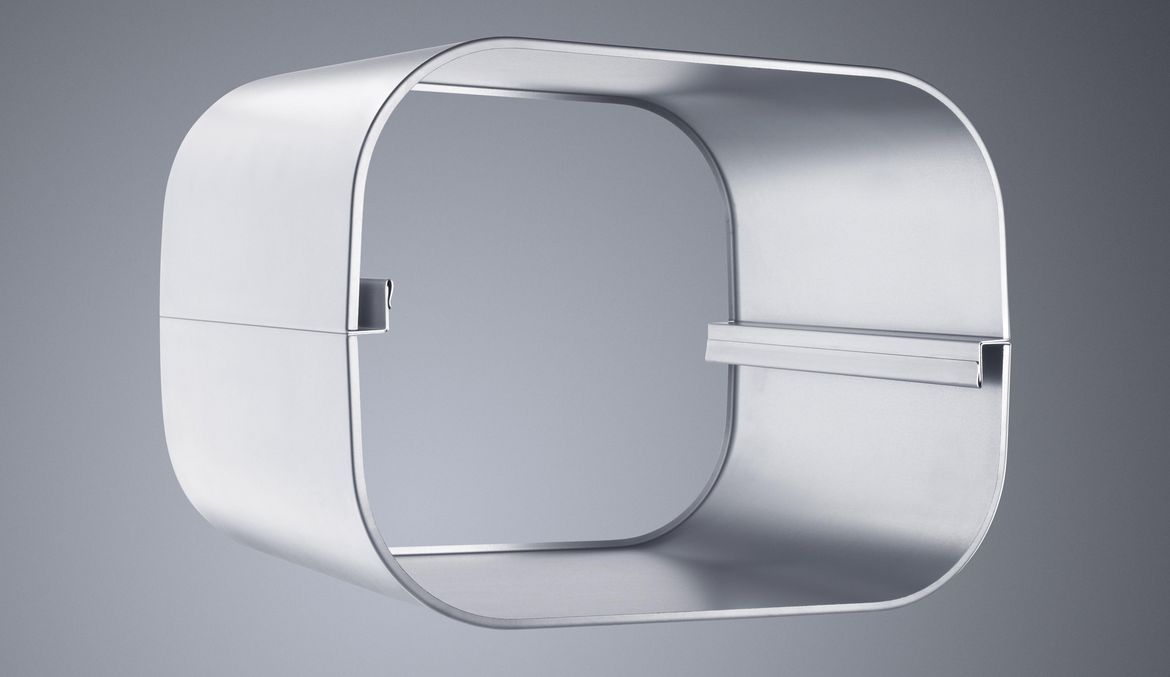

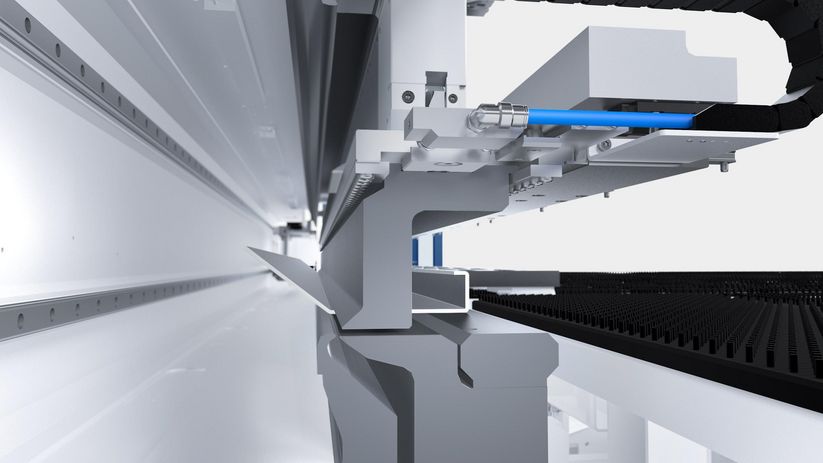

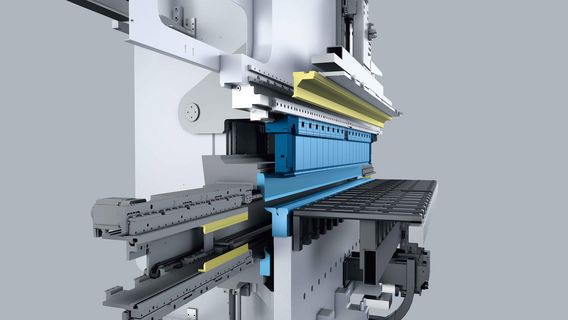

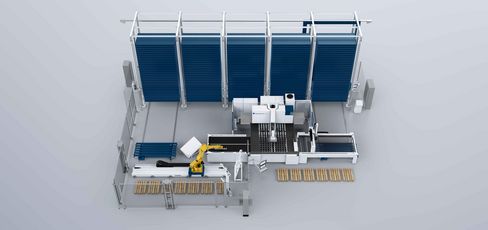

Imagine a production process in which every challenge becomes an opportunity: complex shapes are created effortlessly, perfect surfaces are a matter of course and short cycle times are standard. The TruBend Center Series 7000 sets new standards in panel bending – the process enables mark-free bending for flawless results and offers maximum flexibility for changing lot sizes, materials and tasks. Precise and efficient processes are guaranteed, while intuitive automation eliminates uncertainties and makes it easy to get started – without any hurdles. The system can optionally be integrated directly into interlinked production lines, thus increasing the efficiency of your production. Because automation is the future.

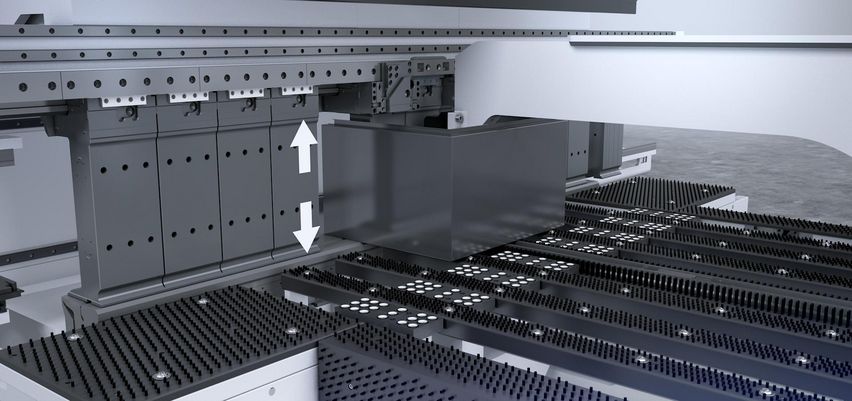

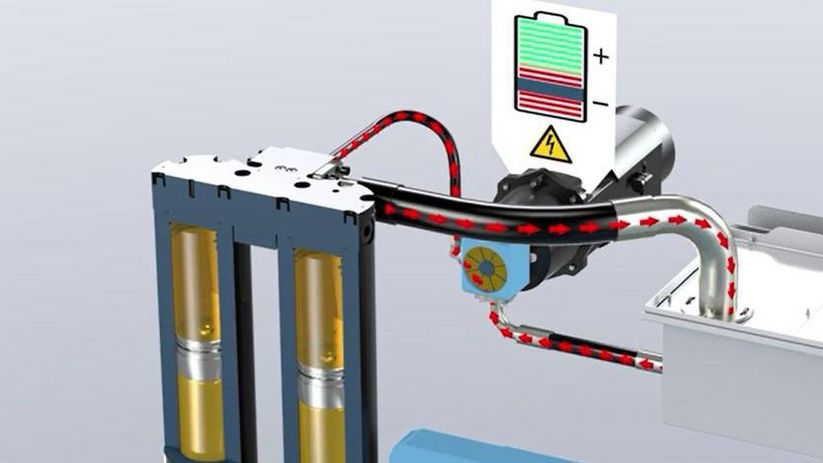

Because automated material handling, flexible gripper systems and tool changers and a wide range of software enable networked, automated processes.

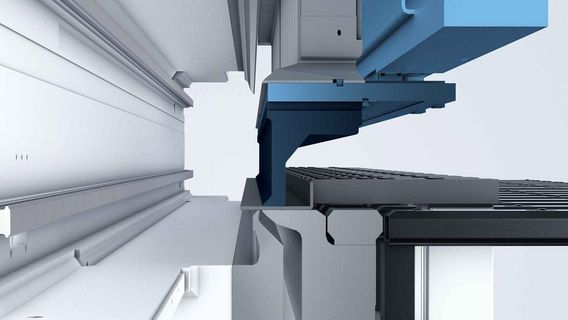

Because the fully automatic manipulation of the parts, and fast edge direction changes enable maximum efficiency and short cycle times.

Because intuitive operation and simple offline programming with the TRUMPF TecZone Bend software make even complex sheet metal parts accessible.

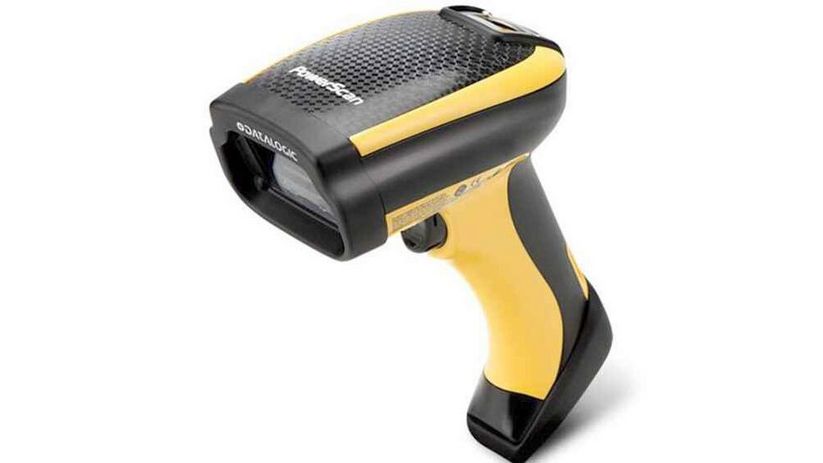

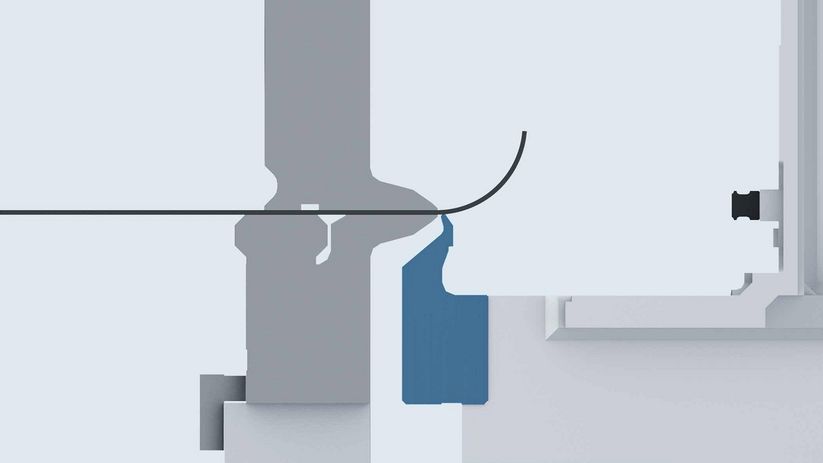

Because the patented angle sensor ACB laser automatically corrects every bend, ensuring high part quality in the long term.

Because fast solutions count in everyday production, technical support, targeted training and high-quality TRUMPF bending tools ensure smooth processes.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- 3 mm möglich bei einer max. Länge 2000 mm

- 3 mm möglich bei einer max. Länge von 1400 mm