Series production is beneficial in many areas including in the forging industry. For this reason, forge heating units are integrated into induction forge heating systems directly in production. Considerable advantages are achieved over traditional furnaces. Low space requirements and no power supply issues are just two of these. Furthermore, inductive forging means no effluent gases, no combustion products and no excessive heat radiation.

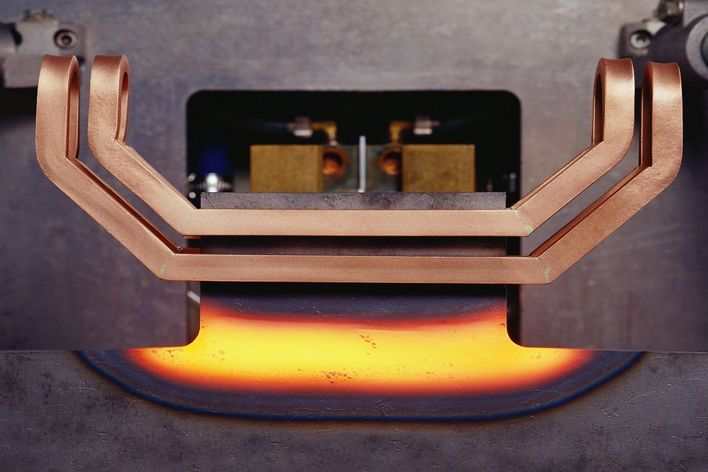

Induction forging

Reaching the correct deformation temperature quickly and environmentally friendly

The benefits of induction forging are:

- No case decarburization and no formation of coarse grains

- Less scaling due to short heat-up times

- Increased service life of forging dies

- Reduced the number of rejects due to even temperature

- Immediate operational readiness, short set-up times

Products

TruHeat HF Series 1000 / 3000 / 5000

High power, compact format

TruHeat MF Series 7000 (G2)

The combination makes it unique

Contact