Commercial vehicles and transport

From tanks to ship panels and even chairlift mounts, TRUMPF's tools process an enormous range of materials in the transport industry.

Globalisation is a major driver throughout the transport industry. With its power tools, lasers and machine tools, TRUMPF provides complete solutions for processing thin and thick sheet metal in this industry. By repairing engine components using 3D printing, industrial customers can also save a lot of time and money compared with conventional methods.

Agricultural and construction machinery

Structural frames, exhaust pipes, driver's cabs, mounts and brackets in agricultural and construction machinery are all made from sheet metal. The laser tube cutting machines from TRUMPF cut the extremely long profiles which are typical of this industry, and simplify downstream process steps such as welding or assembly. Laser welding offers major time savings here, while still ensuring visually top-quality seams in exterior housings. With their large open heights and press force of up to 1,000 tonnes, TRUMPF bending machines are efficient powerhouse models for processing the very large, high-tensile steel parts which are often found in the commercial vehicles sector.

Shipbuilding

To handle high-power applications in shipbuilding, TRUMPF can combine laser welding with another welding process. In this way, large sheet metal plates measuring up to 30 metres long and 15 millimetres thick can be welded when building cruise liners, for example. TRUMPF power tools are highly valued by the shipbuilding industry, particularly for preparing welding edges, implementing visible edges and for deburring work. The industry also benefits from laser metal deposition – in contrast to conventional manufacturing methods, significant savings in material costs and process costs can be achieved when repairing a piston groove for the ship's engine, for example.

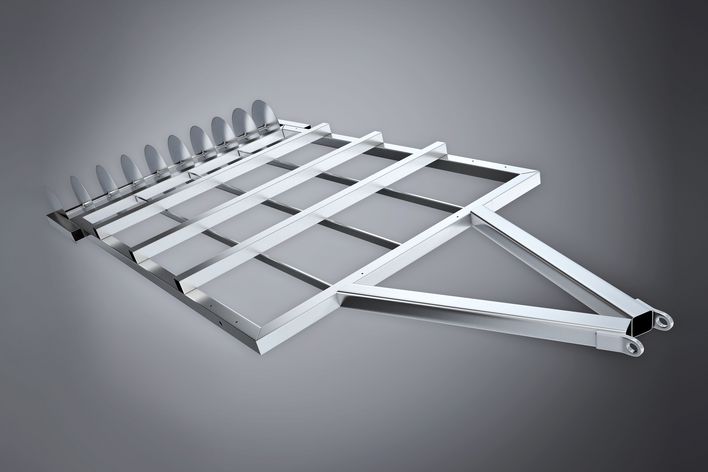

Cable car construction

All major global manufacturers of cable cars use power tools from TRUMPF. The tools can be used flexibly, even for a lot size of just one. This is a major advantage for customers from the cable car construction industry, as they mainly require project-specific components for skiing and hiking regions. For example, TRUMPF tools can prepare weld seams on contours for guide rollers on cable cars and chairlifts.

Rail vehicles

Manufacturers of rail vehicles need to achieve large lot sizes as many wagons often need to be supplied simultaneously for an order. To this end, TRUMPF bevellers process long sheet metal parts, whilst edge trimmers chamfer and round off contours. When it comes to repair work and customised solutions, customers also benefit from our power tools, which are quickly ready for use.