Quick programming, safe welding

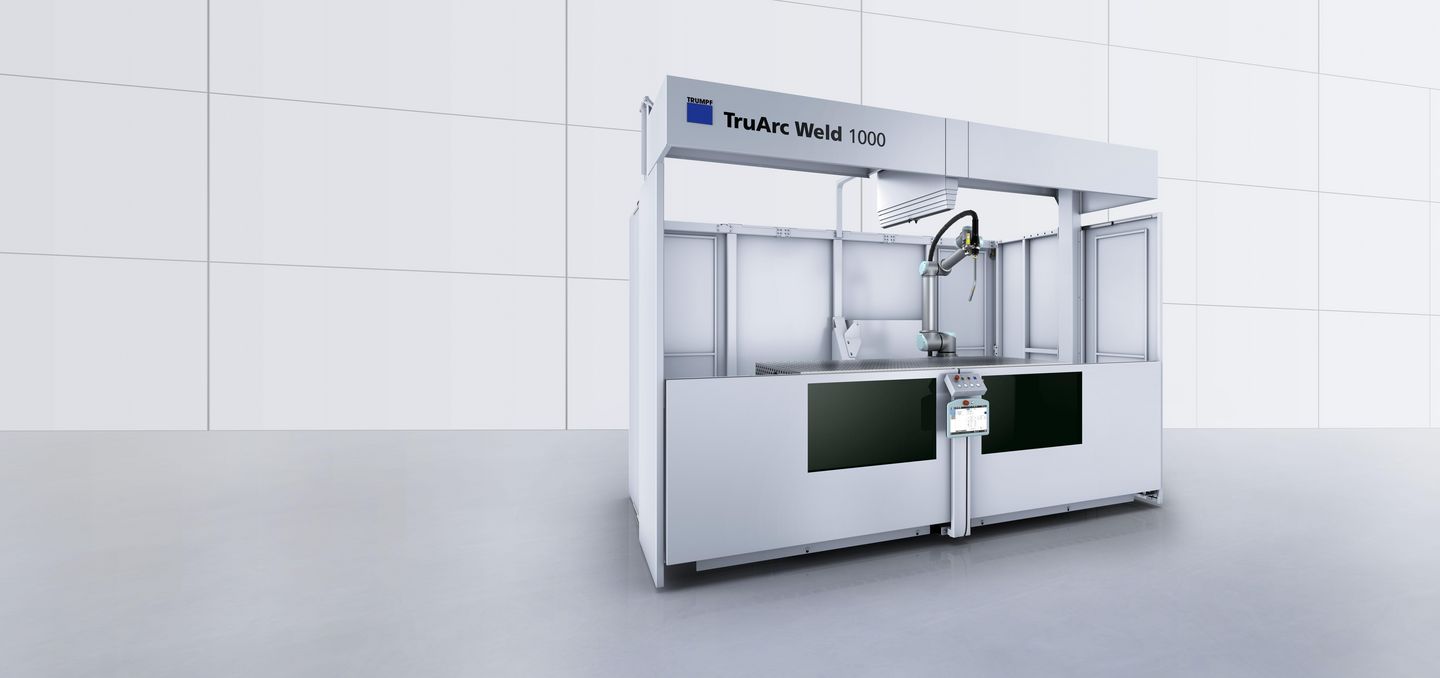

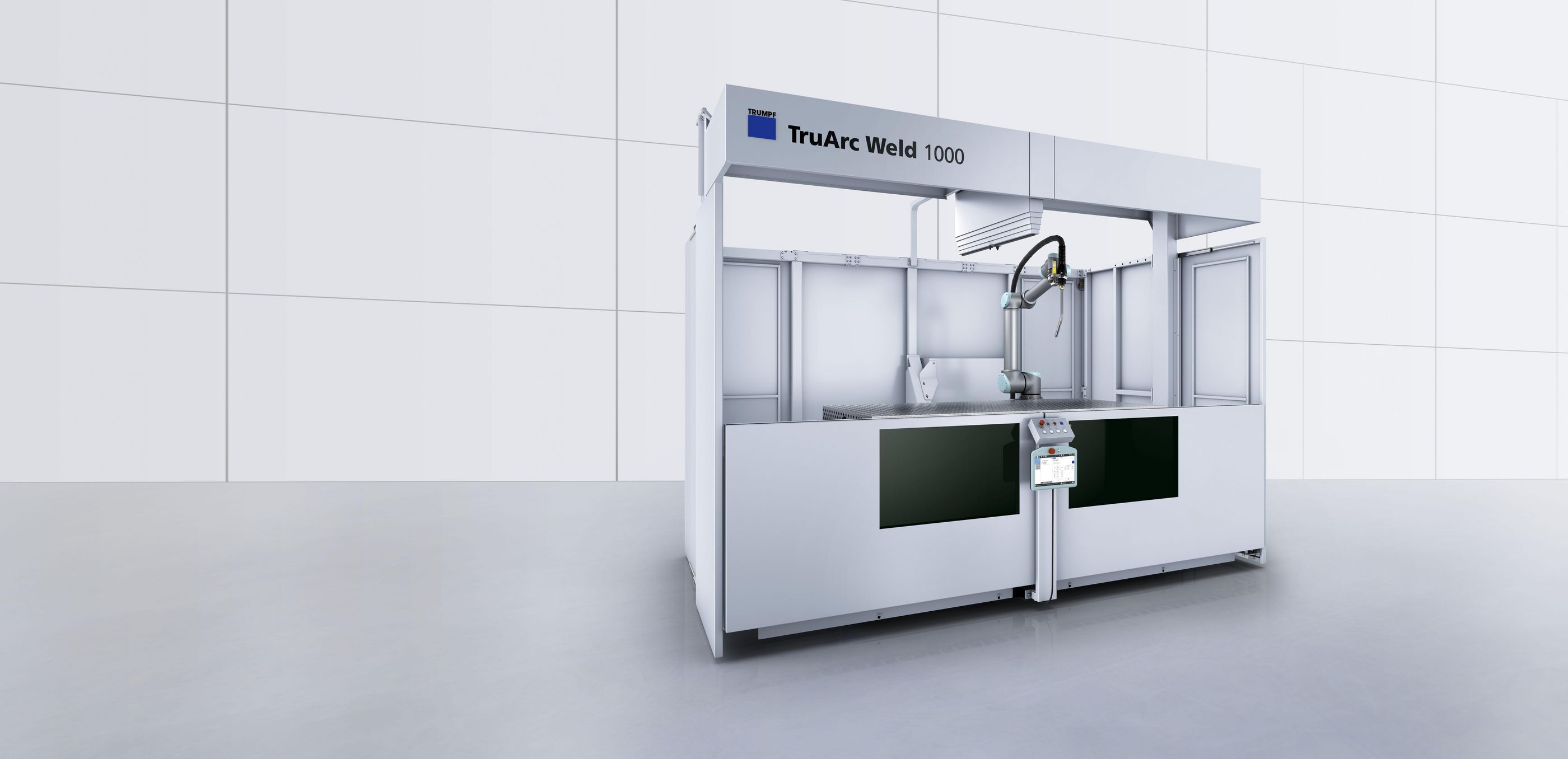

The welding cell is a fully equipped machine tool, tested by the Technical Supervisory Association (TÜV) and certified with CE. This includes an exhaust system, housing with anti-glare protection and safety equipment in line with TRUMPF standards. You can launch, program and operate the welding cell with very little training - video tutorials will do the job. You can utilise the welding cell in one- or two-station operation, depending on the component and lot size. This means, for example, that you can either process a larger component or smaller components in larger batches parallel to production.

Using the operating unit on the welding torch and simple programming directly at the robot control

Safety cabin with anti-glare protection, self-cleaning exhaust system, LED lighting and collaborative robot

Set the machine up at the desired location and start operation within just a few hours

Thanks to high-performance equipment from Fronius and set-up parallel to production using two-station operation

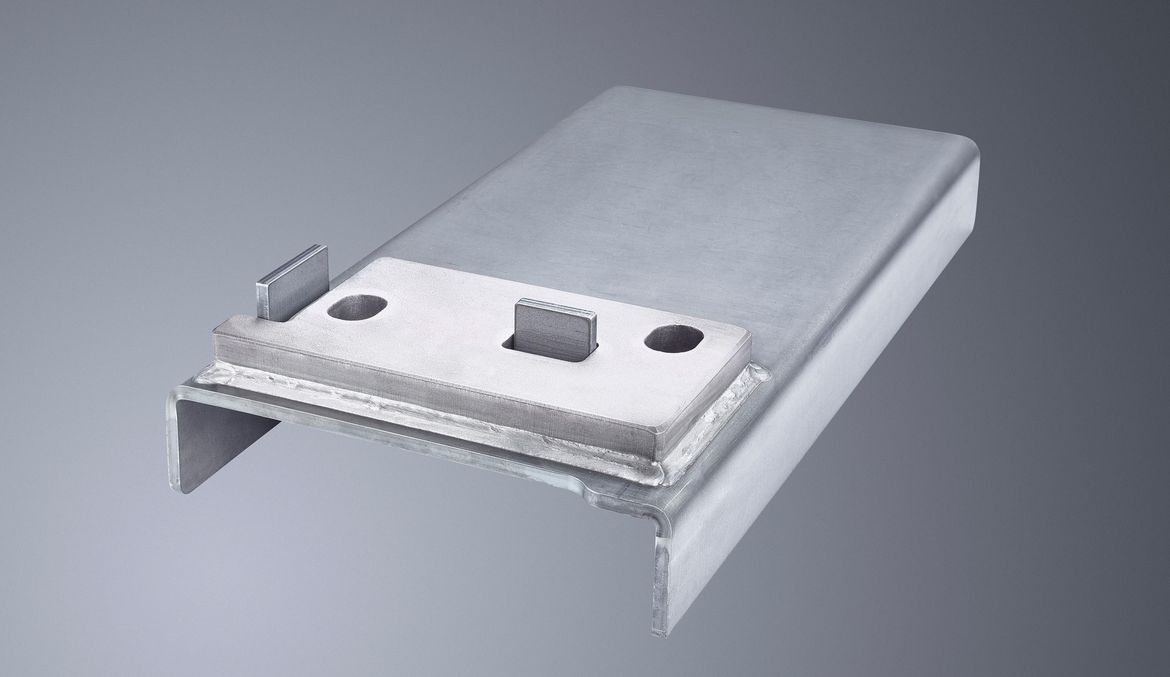

Console

Console made of mild steel, 25 mm plate on 8 mm curved sheet metal with five weld seams. Even for just one piece, automated welding of this component is 21% faster (including programming) than manual welding.

Transport securing device

Transport securing device made of 6 mm mild steel. Thanks to this component, you can save 63% with automated welding compared to manual welding, starting from a lot size of 8.

Junction box

Junction box made of 3 mm chromium nickel-steel. The CMT welding process from Fronius applies very little heat to the component. Thanks to its consistent surface shingling, the weld seam satisfies high visual demands.

Aluminium I-joint

This sample part shows CMT-welded aluminium as an I-joint with a thickness of 1 mm.

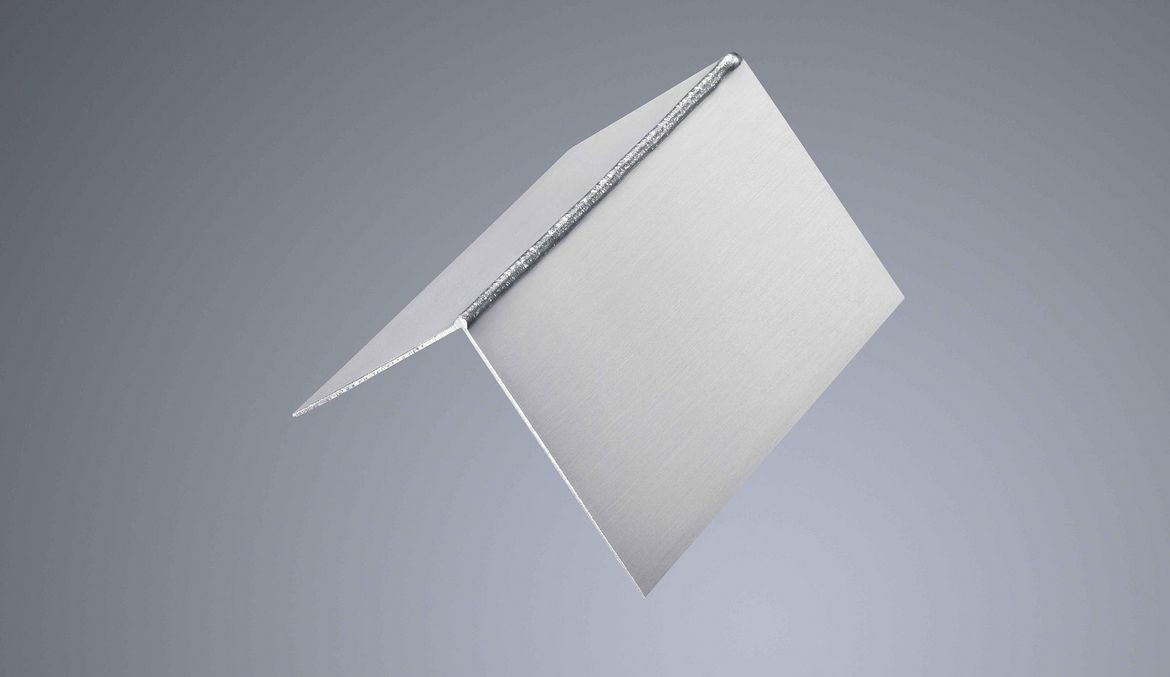

Stainless steel corner joint

This sample part shows welded stainless steel as a corner joint with a thickness of 1 mm.

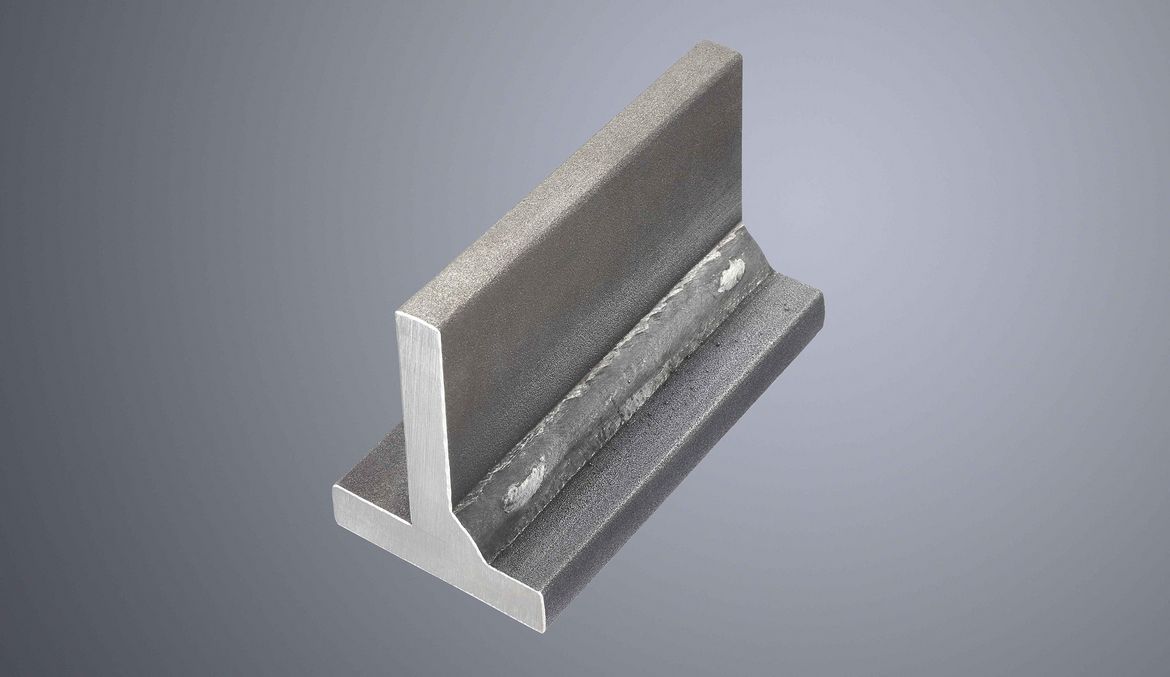

Mild steel T-joint

This sample part shows welded mild steel as a T-joint with a thickness of 8 mm.

|

TruArc Weld 1000

|

TruArc Weld 1000

|

|

|---|---|---|

| Axis data | ||

| Type | Collaborating industrial robot arm | Collaborating industrial robot arm |

| Number of axes | 6 | 6 |

| Range | 1300 mm | 1300 mm |

| Repetition accuracy | +/- 0.05 mm | +/- 0.05 mm |

| Welding source | ||

| Type | FRONIUS TPS 320i C PULSE | FRONIUS TPS 320i C PULSE |

| Welding current range MIG/MAG | 3 A - 320 A | 3 A - 320 A |

| Dimensions and weights | ||

| Cabin dimensions | 3605 mm x 2454 mm x 2818 mm | 3605 mm x 2454 mm x 2818 mm |

| Weight | 2940 kg | 2940 kg |

| Work area | ||

| Typical maximum part size (with closed telescopic centre separation) | 600 mm x 600 mm x 600 mm | 600 mm x 600 mm x 600 mm |

| Typical maximum part size (with open telescopic centre separation) | 2000 mm x 600 mm x 600 mm | 2000 mm x 600 mm x 600 mm |

The technical data of all product versions as a download.

Smart Seam Tracking is revolutionising teaching on the TruArc Weld 1000. With this intelligent online seam monitoring, all you need to do is bring the welding torch to near start position, the Cobot takes care of the weld upset distance and torch orientation. The welding torch remains perfectly set up across the entire seam and the welding path is adjusted live during welding.

Combination of intuitive operating unit on the welding torch and simple programming directly at robot control for minimum programming times. The design of the machine's central operating unit is simple and clear.

Safety cabin with integrated exhaust system, automatically opening anti-glare protection and lighting. The extendible partition wall divides the work area for two-station operation if required.

The cabin-free machine version is suitable for projects with particularly large components. No safety cabin or exhaust system, but still the proven performance and precision. Maximum flexibility for your requirements.

Collaborative robot UR10e with six axes and force moment sensor. The linear axis positions the robot on the left or right.

High-performance welding equipment from Fronius: TPS 320i C PULSE welding source including welding package PMC, ultra-slim 350 ampere torch and external wire feed system.

3D work table with hole pattern D16 in a 50 x 50 mm grid and hardened surface. The table's dimensions are 2000 x 1000 x 100 mm.

User-friendly loading of heavy and large components and devices is possible with this option. To do so, the cab cover is opened individually over the two stations and the component is loaded into the machine interior by crane.

The optional technology package CMT welding ensures higher process reliability and energy-reduced welding with fewer weld spatters and little distortion with the TruArc Weld 1000.

Pendulum welding is particularly beneficial for thick sheet processing. You can prevent a lack of fusion with wide weld seams.

Seamless integration of many TRUMPF machines into your own software environment is very easy. We have the right solution for every combination, whether it be integration into Oseon or a connection to monitoring and analysis tools. A connection to third-party software systems is also possible with our interfaces based on the OPC UA standard.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.