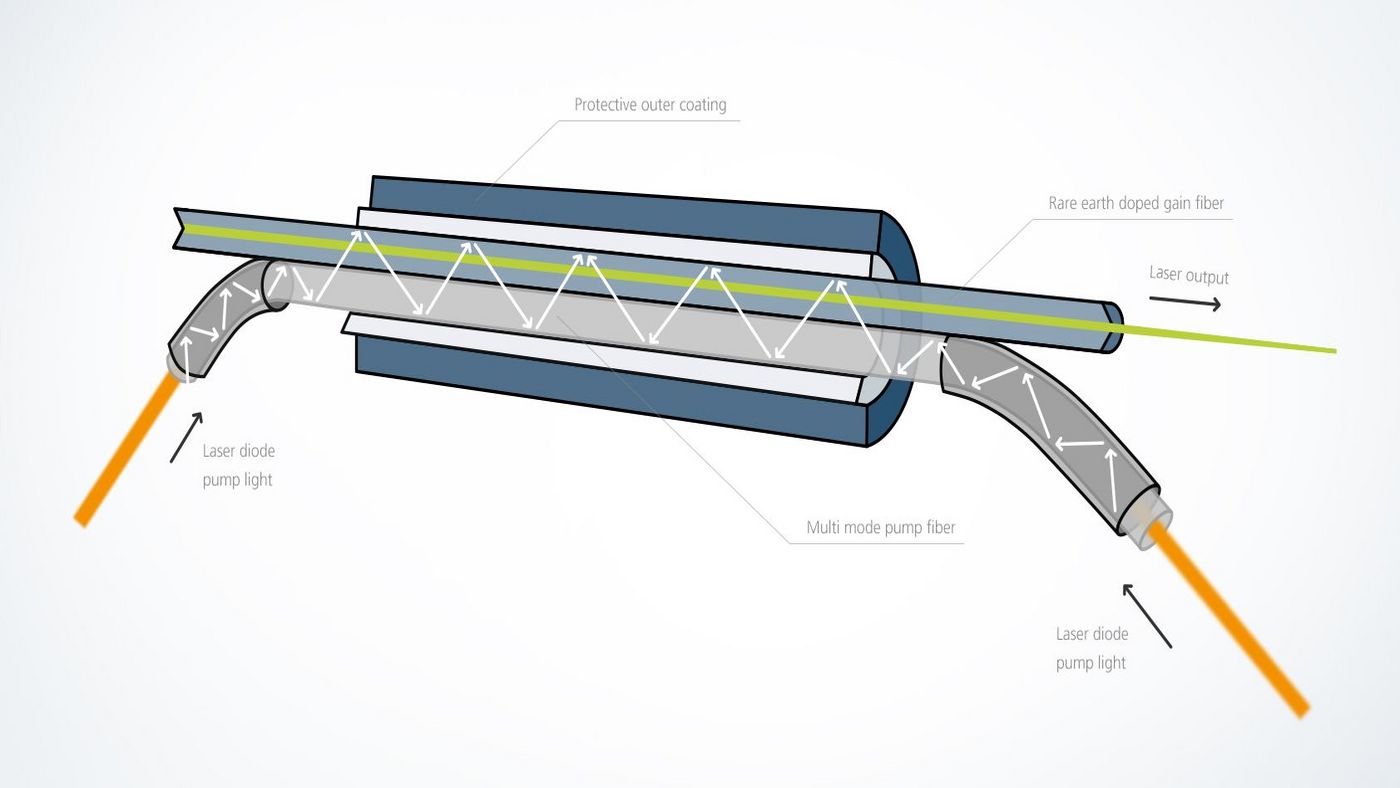

All lasers have three key elements in common: An excitation source, a gain medium, and a resonator. The excitation source uses externally supplied power to put a gain medium into an excited state. This excited state of a laser medium is characterized by a so-called population inversion, which enables the medium to amplify light due to a physical process called stimulated emission, first described by Albert Einstein (LASER = “Light Amplification by Stimulated Emission of Radiation). Fiber bragg gratings inside the fiber act as mirrors around the gain medium to form an optical resonator, which on the one hand traps optical energy inside the resonator for further amplification, but also enables the out-coupling of a certain part of the optical energy in one direction by means of a partially transparent mirror. This out-coupled part of the optical energy is the laser beam that can be used for various purposes.

TRUMPF has developed in-house a proprietary scheme for coupling the light from the pump laser diodes into the active medium of the gain fiber. The scheme, known as ‘GT-Wave’ (see diagram) has the pump fiber held in contact with the gain fiber over its whole length, of many meters. Some of the pump light enters the gain fiber each time the internally reflected rays impinge on the interface. As these rays then cross the rare earth (Ytterbium) doped core, they are partially absorbed and excite the gain medium. Thus over the length of the gain fiber, all the pump light is smoothly and continuously absorbed. This scheme offers advantages of ease of scaling to higher laser powers with addition of extra pump modules, the avoidance of ‘hot-spots’ on the end faces of the gain fiber from usual end pumping schemes and a uniform gain profile from the deposition of the pump energy along the length of the gain fiber.

So a fiber laser is a type of laser which uses fiber doped with rare-earth elements (erbium, thulium, ytterbium) etc. as active laser medium. This differentiates the fiber laser to other types of laser available on the market, where the active laser medium is a crystal (e.g. disk laser) or gas (e.g. CO2 laser).

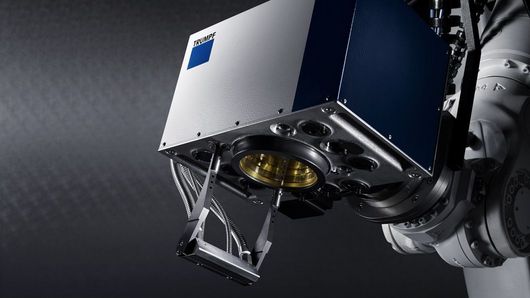

Fiber lasers provide absolute efficiency, precisely control speed and power through accurate management of the beam length, duration, intensity, and heat output.