Parameters

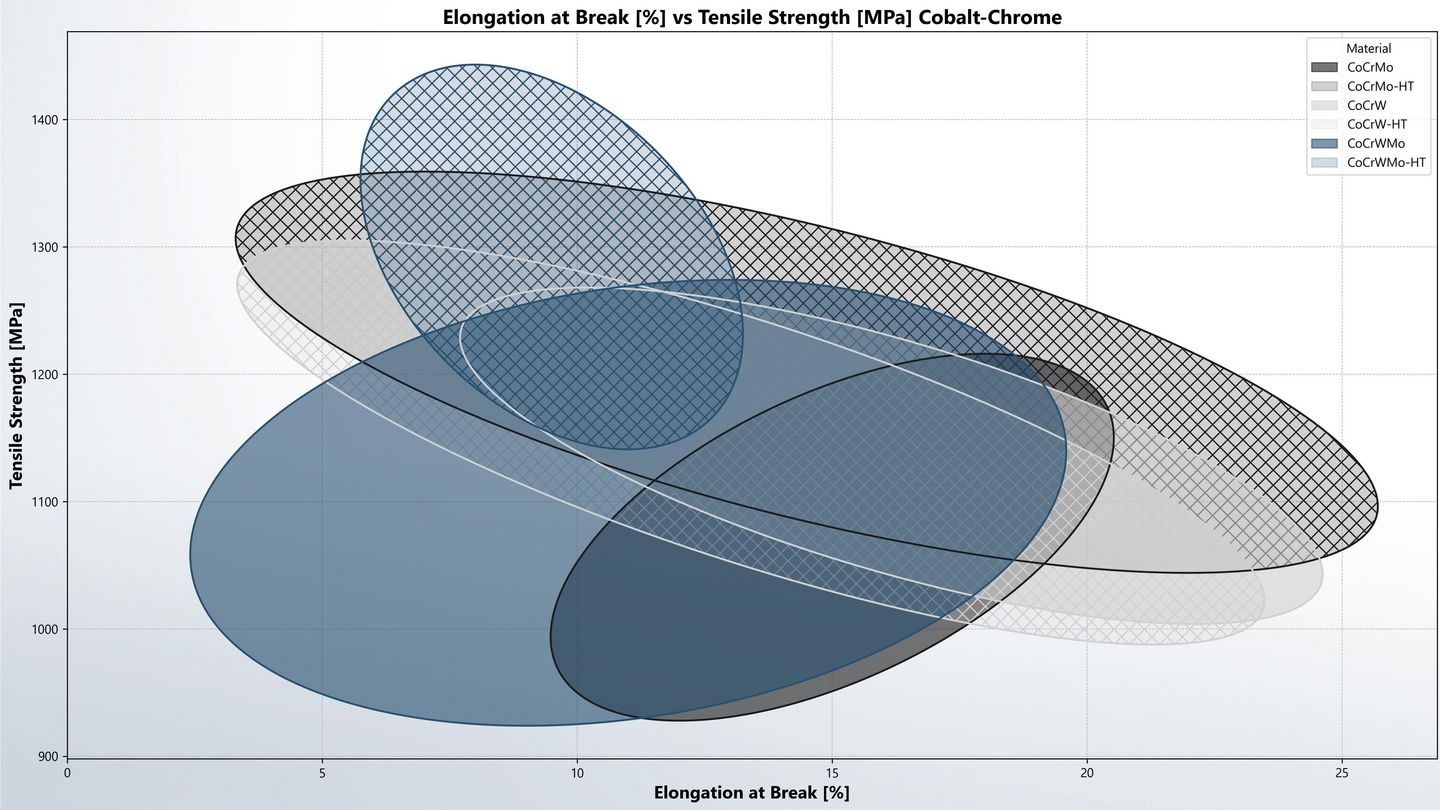

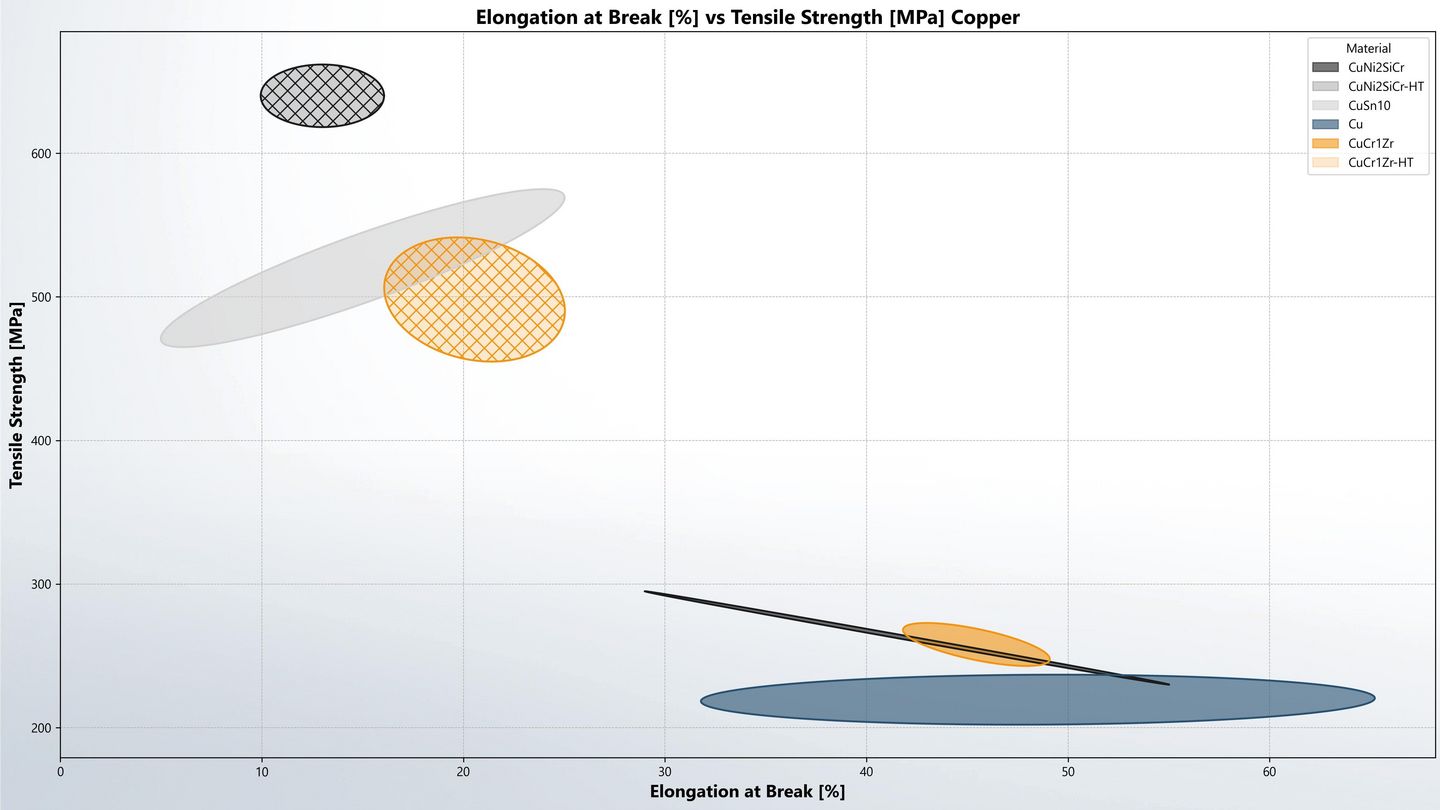

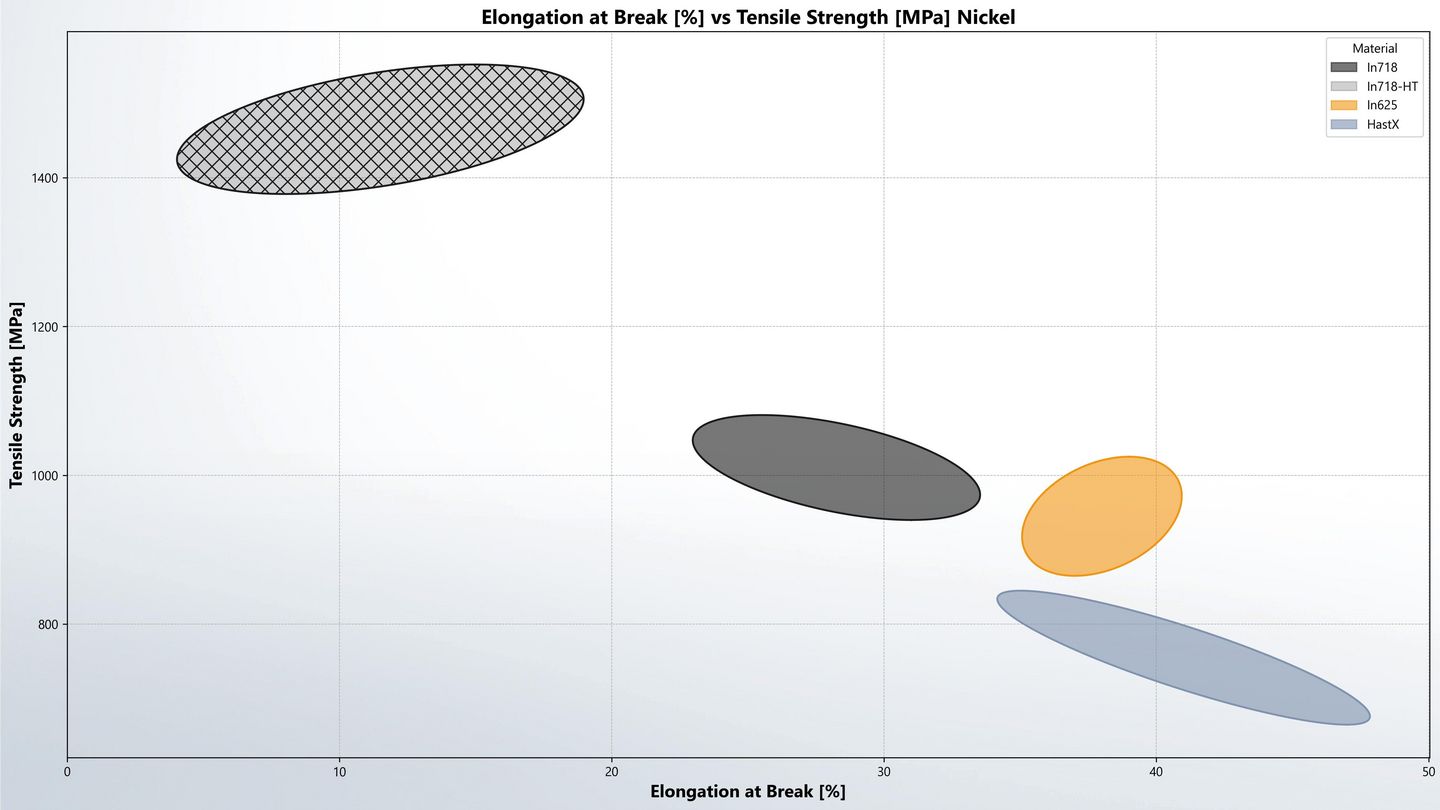

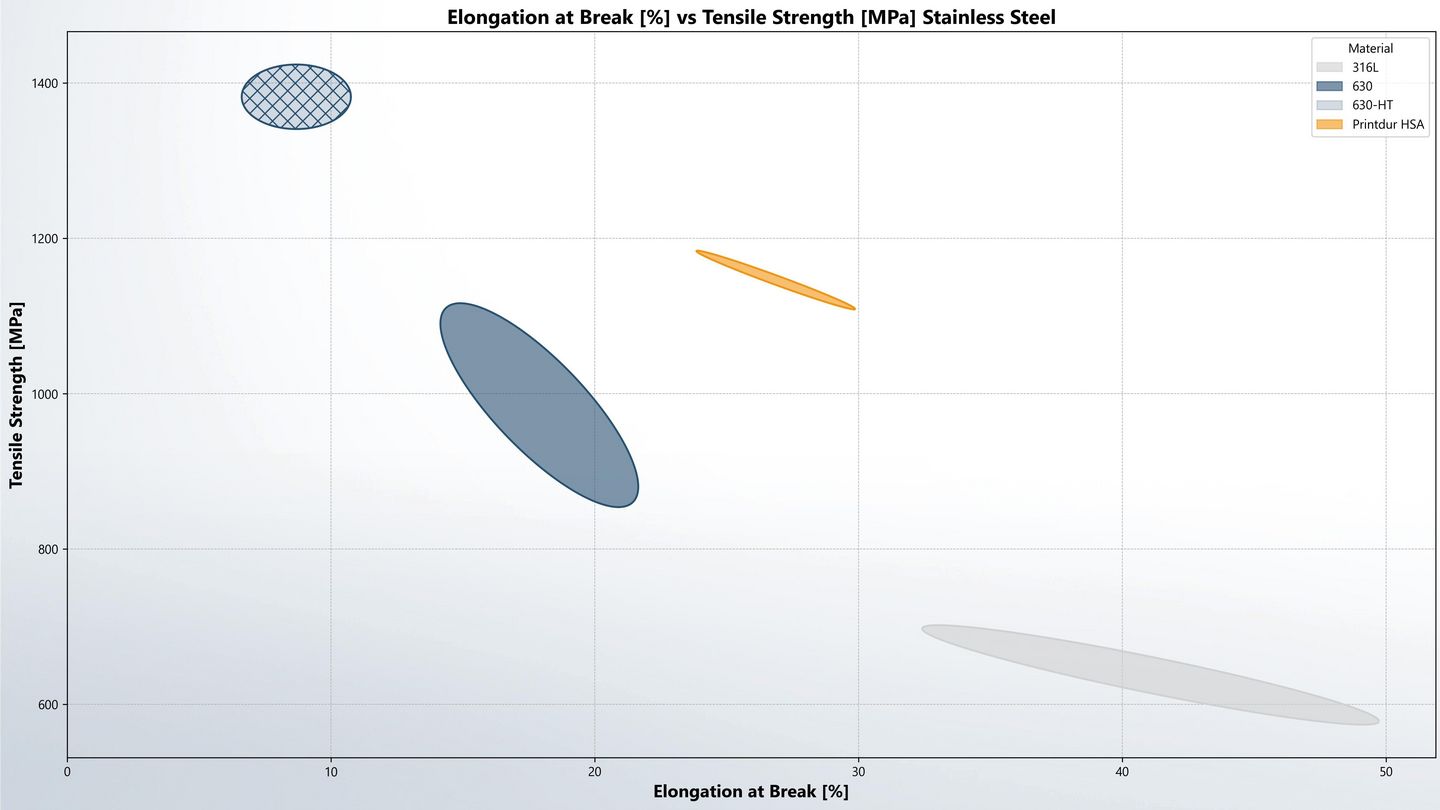

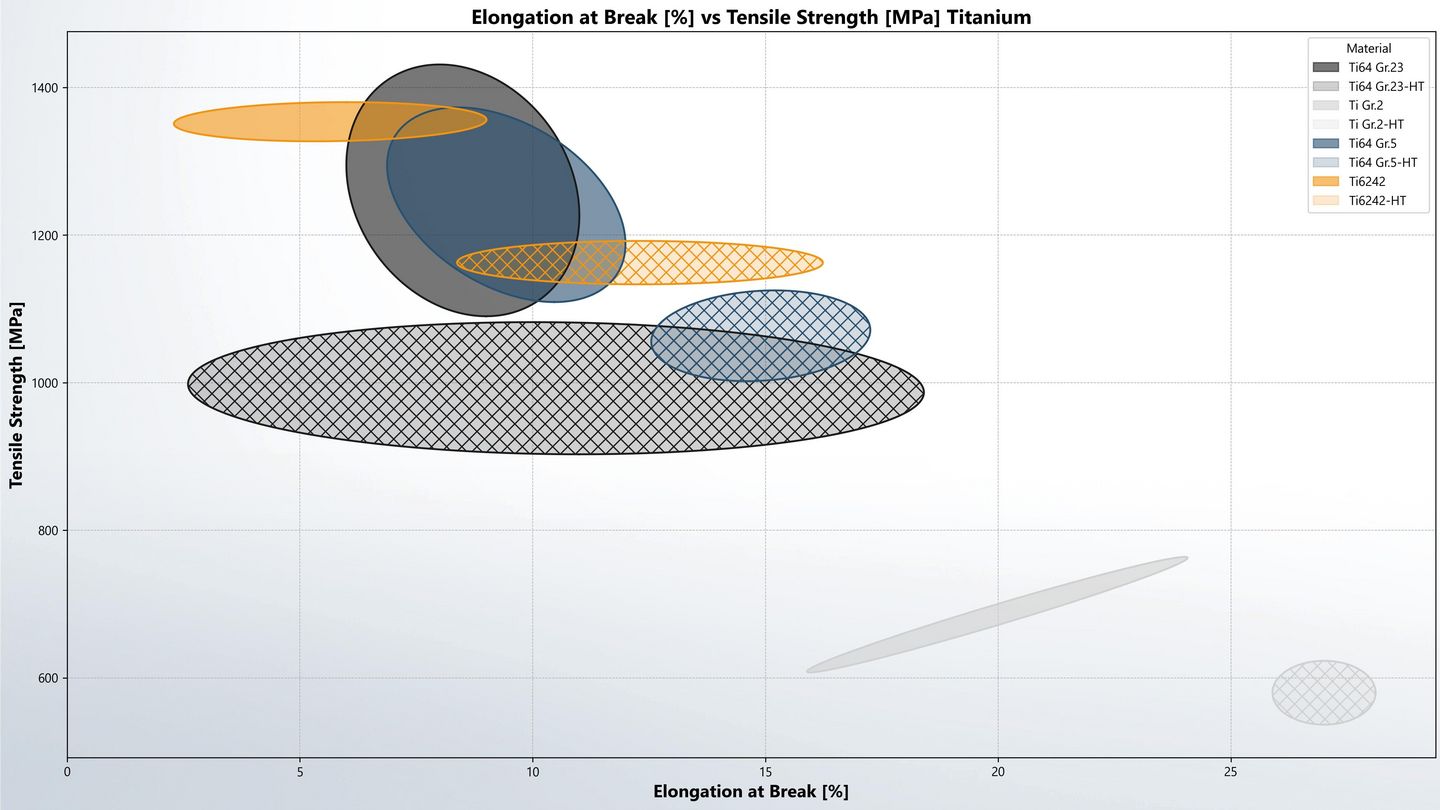

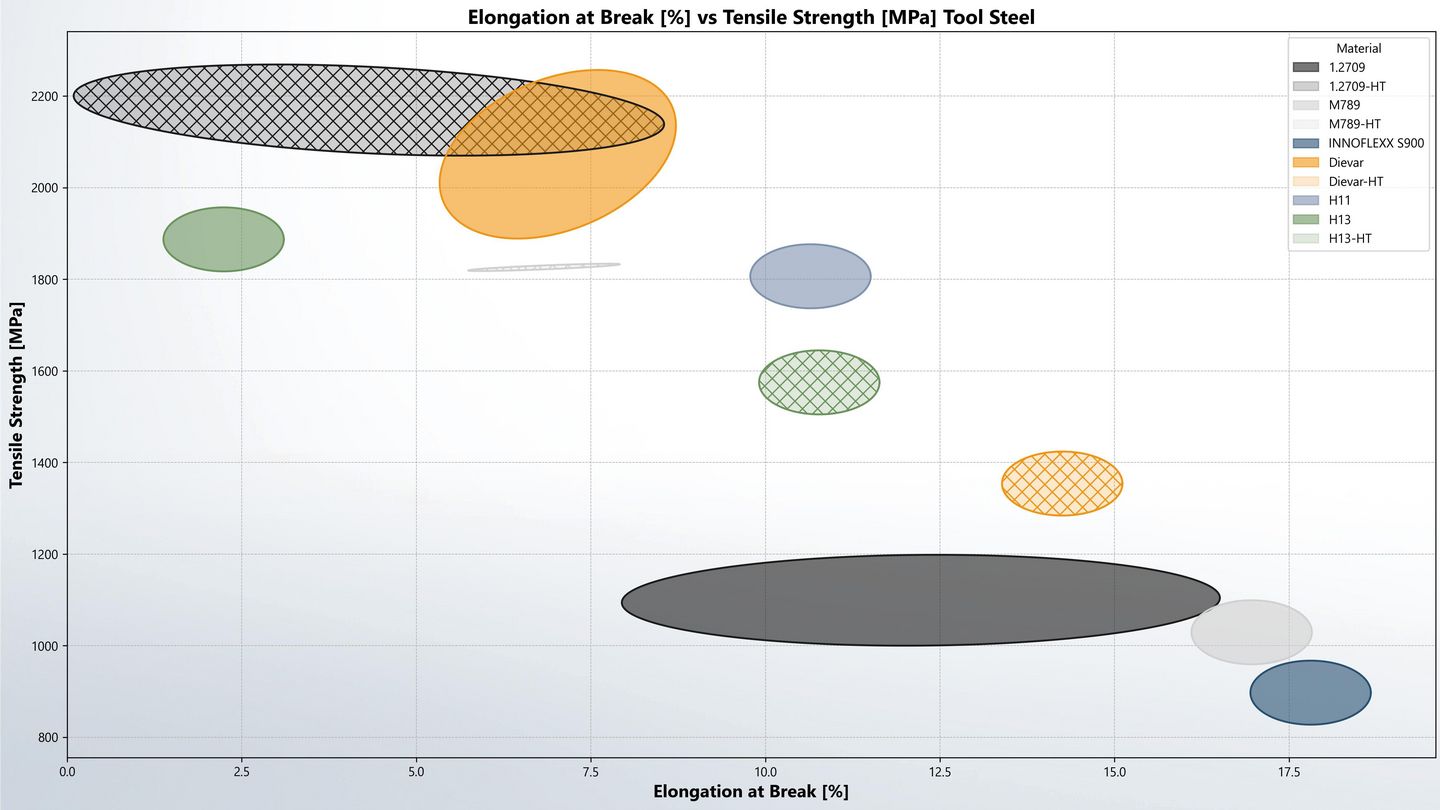

Parameter settings are essential in metal additive manufacturing because they directly influence the quality, mechanical properties and reproducibility of the printed parts. Each machine and material requires specially developed parameters to ensure optimal results. Below is a concise summary of the main properties of commonly used materials, in combination with applicable heat treatments in metal additive manufacturing.

Overview of material properties

Access further details about our parameter data

Welcome back!

We are unlocking access to exclusive content for you!

We are currently reviewing your data...

Just one more step to gain access!

Many thanks for your interest in our exclusive content. Please open your inbox and confirm your address. Then you'll receive full access. Please check your spam folder as well.

Access not possible

Unfortunately, your registration for our exclusive content was not successful. Please contact us at info@trumpf.com or use the contact form.

Unfortunately, an error has occurred. Please try again later.